The MABR−MBR demonstration plant at Ulu Pandan, Singapore

Simon Judd visited Singapore's Integrated Validation Plant project at Ulu Pandan. Recognised as the 'Water/Wastewater Project of the Year' at the 2018 Global Water Awards, this project currently focuses on exploring advanced technologies like MABR and AGS−MBR to achieve process intensification, energy efficiency, and optimized used water treatment processes.

1. Water and Singapore

Singapore is widely recognised as having one of the most advanced national water management, conservation and reuse schemes in the world. In addition, some of their tourist attractions make spectacular use of water – for example, the indoor waterfall in the Cloud Forest dome at the Gardens by the Bay, the Oculus at the Marina Bay Sands complex, and the evening light shows at the bay front.

Municipal water supply and wastewater treatment in the country is managed by PUB, Singapore’s National Water Agency. The 12,500 m3/day-capacity Integrated Validation Plant (IVP) began operation at the Ulu Pandan Water Reclamation Plant site in 2017. This research facility forms a key part of developing and testing wastewater treatment technologies prior to full-scale implementation.

2. MBR technology implementation in Singapore: a brief history

MBR development in Singapore began in 2003 with the now-decommissioned Bedok Water Reclamation Plant (Bedok WRP) site, where three 300 m3/d pilot plants were installed (Lay et al, 2017). The success of those trials, which effectively demonstrated the superiority of the MBR−RO process over the established classical CAS−MF/UF−RO reuse scheme, led to the construction of a 23 MLD demonstration plant at the Ulu Pandan site in 2006.

A key performance parameter in MBR technology is specific energy consumption (SEC). The lowest SEC attained from the original Bedok pilot trials was around 1.3 kWh/m3. Successive trials at the Ulu Pandan demonstration plant led to establishing a SEC consistently below 0.5 kWh/m3 through optimising the membrane flux, membrane and process aeration, and key process operating conditions such as the SRT, corresponding MLSS concentration and the DO set point (Lay et al, 2017).

In 2013, the WRP at Jurong, a conventional tertiary polishing scheme based on coagulation−sand filtration, was converted to an MBR scheme. This 68-MLD plant, together with the Ulu Pandan WRP, delivers water for industrial (non-potable) use. The conversion reduces both space and chemicals consumed.

In 2015−16, the large WRP at Changi was retrofitted with MBR technology, placing membrane modules into the existing bioreactor process trains. This boosted the plant capacity by 15%. Subsequent optimisation of the aeration for one of the four lanes at Changi was demonstrated to reduce the SEC to around 0.4 kWh/m3 (Lay et al, 2017).

The latest large wastewater reuse construction project is at Tuas (TWRP) to the west of the country, and is fed by both industrial and municipal effluent streams. Both streams are to employ MBR technology as the biological treatment step, with an enhanced primary sedimentation step employed for each stream.

3. The IVP at Ulu Pandan

The Integrated Validation Plant (IVP) project aims to assess and validate innovative water reuse technologies for potential deployment, such as at TWRP. Originally modelled with Tuas WRP in mind, it was designed to maximize energy recovery and efficiency. Since 2021, the focus has shifted to exploring advanced technologies like MABR and AGS (aerobic granular system)−MBR to achieve process intensification, energy efficiency, and optimised water reuse treatment processes. Recognised as the 'Water/Wastewater Project of the Year' at the 2018 Global Water Awards, IVP continues to integrate new process systems to meet these goals.

3.1 Process design

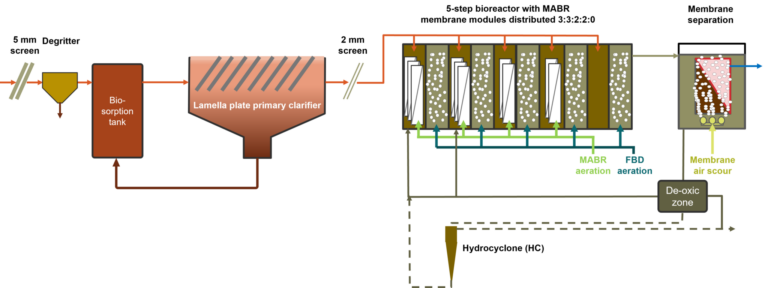

The IVP has two parallel trains, one being a conventional bioreactor with membrane separation and the other with an MABR as the bioreactor. For the MABR train (Fig. 1), the RAS (return activated sludge) is returned to the anoxic zone of both basins 1 and 2, while for the conventional train it is returned only to the basin 1 anoxic zone.

The IVP process treatment scheme has two trains for the liquid flow, each comprising:

- band screen (5 mm)

- cyclonic degritter (Fig. 2a), with classifier (Fig. 2b) for the collected grit

- 'biosorption tank' (Fig. 3): an enhanced sedimentation process in which biomass is introduced into the biosorption tanks by recycling primary sludge to assist with removal of organic carbon and fine solids through adsorption

- rapid sedimentation, with lamella plates (Fig. 4) and mechanical scraper for scum removal

- band screen (2 mm rating)

- step-feed bioreactor with five basins

- MABR technology (Fig. 5) retrofitted into one of the two trains in March 2024, and comprising ten hollow fibre (HF) modules distributed 3−3−2−2−0 across the five basins, and

- membrane separation (Fig. 6), comprising two trains, each with eight cassettes consisting of 48 modules.

The sludge processing comprises:

- a de-oxic zone fed by the MBR RAS at a return ratio of 1Q and providing an HRT of 5 hrs for DO removal/diminution, and

- a hydrocyclone (HC) to recover and concentrate dense solids from the bottom of the deoxic zone outlet stream, and the HC underflow (outlet solids fraction) is returned to the first anoxic basins.

A novel aerobic granular system (AGS) is currently being tested at the site. The proprietary AGS is a three-step auto-controlled sequencing batch reactor (SBR) comprising (a) simultaneous fill and draw, (b) aeration, and (c) rapid settling assisted by granulation of the sludge solids.

It is expected for the AGS−MBR system to achieve the following benefits:

- reduction in energy consumption compared to current IVP step-feed bioreactor with aeration energy and recirculation energy

- reduction in sludge production compared to typical step-feed bioreactor operating at a short to moderate SRT, and

- treat excess wastewater during wet weather conditions (up to 3Q) to regulated discharge standards.

The AGS can be fed from either:

- the raw (i.e. coarse-screened and degritted) feedwater, and/or

- the settled primary effluent.

The AGS-treated effluent can either be fed to the MBR or discharged, depending on the quality achieved. The AGS excess sludge solids can be fed to the MBR.

3.2 Process operation

Details of the study have previously been reported at the 2018 IWA Congress (Tao, 2018).

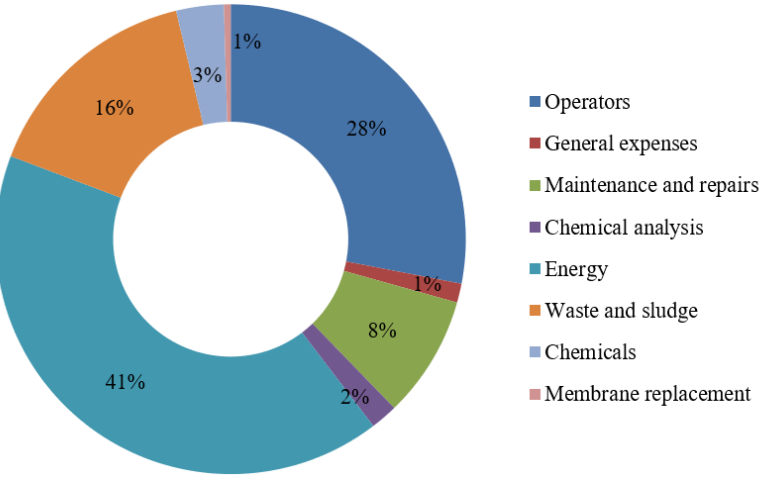

The biological step is operated at an HRT of 5h and an SRT of 5−10d. This contributes to a very low MLSS of 2 g/L in the biological tank and 4 g/L in the membrane tank at the recirculation ratio of 1Q. The low membrane tank MLSS concentration, combined with a relatively conservative net flux of 20 LMH, permits a very low membrane specific aeration demand (SADp). This is instrumental in sustaining the low SEC.

The success in suppressing membrane fouling and clogging has been demonstrated by:

- sustained operation at an MBR membrane permeability between 200 and 240 LMH/bar for the majority of the time, and

- no requirement for chemical recovery cleaning since operation began in August 2017.

3.3 Outcomes

3.3.1 Scoping trials

The original trial, reported in 2018 and featuring in our report of the IWA World Water Congress & Exhibition 2018 − conducted without the MABR installed − established a benchmark SEC for the five-pass step-feed bioreactor process with the advanced primary treatment. Outcomes of this study, for optimised membrane air scouring, demonstrated:

- a membrane air scour SEC (SECm,a) of 0.043 kWh/m3, based on a SADp in the region of 2 Nm3 air per m3 permeate, and

- an overall energy consumption below 0.25 kWh/m3, with biological process aeration contributing about 43%.

The membrane air scour has subsequently been reduced further to a SEC below 0.04 kWh/m3 without detriment to the sustainability of the process. No recovery cleaning has been applied since process start-up – a period of seven years – and the TMP has risen by only 6 kPa over that period.

3.3.2 MABR

The retrofitted MABR has been in operation since March 2024. Through adjusting the MABR membrane aeration rate, the system has achieved a steady-state nitrification rate between 2.2 and 3.2 gN-NH4/day per m2 membrane area.

Treated ammonia concentrations have been consistently below 5 mg/L from an influent concentration of ~40 mg/L. The average removal has been 94% over the course of the year.

A key measure of MABR treatment efficiency is the specific process air flow in Nm3 air per kgNH4 load, which indicates the amount of air needed for nutrient removal. Rates between 35 and 65 Nm3/kgNH3 have been recorded, with the values decreasing with decreasing MLSS concentrations and the lowest values below 40 Nm3/kgNH3 associated with MLSS concentrations of around 2 g/L.

3.3.3 AGS

The AGS was seeded with conventional activated sludge instead of granular sludge. Despite this, the plant achieved the design hydraulic load of 2,000 m3/day and required treated effluent quality (BOD = 20mg/L, TSS = 30mg/L and NH3 <5mg/L) two weeks after start-up – much earlier than the anticipated six weeks. The sludge settleability was confirmed by the SVI5/SVI30 ratio of ~1.0 – corresponding to the target value.

4. Conclusions and forward plan

Compared to the conventional biological + MBR process, the MABR–MBR process has the potential to demonstrate:

- a 20%–30% increase in bioreactor treatment capacity

- a 5%–10% reduction in aeration energy.

A key outcome from future studies will be the determination of emissions, specifically nitrous oxide (N2O). According to the peer-reviewed literature (Kinh et al, 2017), the counter-diffusional biofilms associated with the MABR technology generate lower N2O emissions than the co-diffusion biofilms of MBBRs during simultaneous nitrification and denitrification.

We await the outcomes of future research with interest.

5. Acknowledgments

Grateful thanks to Tai Liyun (Principal Specialist, Liquid Treatment, Used Water Treatment Ops Tech) and Gu Yangshuo (Principal Specialist, Solids Treatment, Used Water Treatment Ops Tech) of PUB for their time, hospitality and patience.