What are membrane bioreactors?

An introduction to MBRs

What are MBRs? Our new pocketbook combines print and digital content...find out more‘Membrane bioreactor’ (MBR) is generally a term used to define wastewater treatment processes where a perm-selective membrane, eg microfiltration or ultrafiltration, is integrated with a biological process − specifically a suspended growth bioreactor.

MBRs differ from ‘polishing’ processes where the membrane is employed as a discrete tertiary treatment step with no return of the active biomass to the biological process.

Almost all commercial MBR processes available today use the membrane as a filter, rejecting the solid materials which are developed by the biological process, resulting in a clarified and disinfected product effluent.

A membrane bioreactor is essentially a version of the conventional activated sludge (CAS) system:

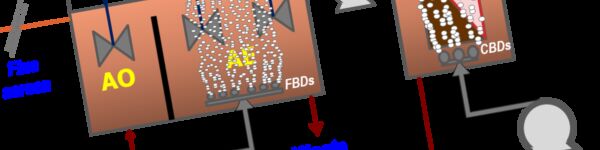

Fundamentals of MBR design − the immersed membrane bioreactor (iMBR) process

While the CAS process uses a secondary clarifier or settlement tank for solid/liquid separation, an MBR uses a membrane for this function. This provides a number of advantages relating to process control and product water quality.

Watch our video for a brief introduction to MBR technology key parameters: