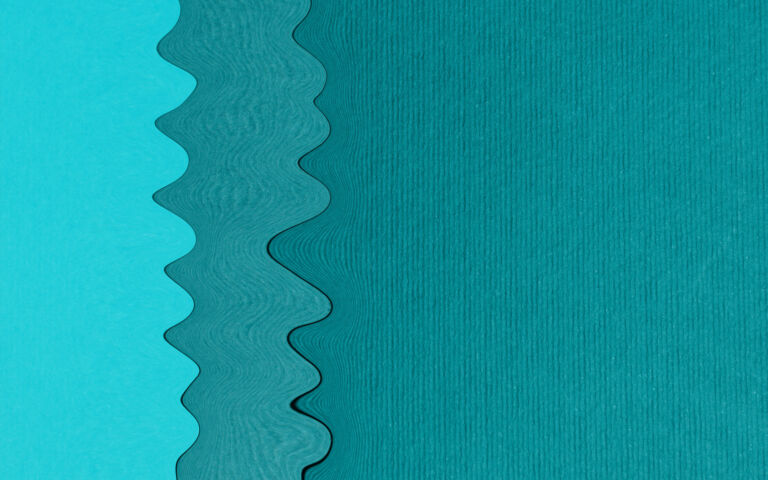

MBR operation & maintenance – dead end vs crossflow

Dead end vs crossflow operation

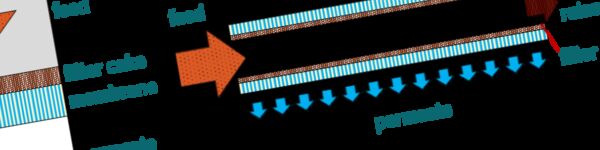

Conventional pressure-driven membrane processes with liquid permeation can operate in one of two modes. If there is no retentate stream then operation is termed ‘dead-end’ or ‘full-flow’; if retentate continuously flows from the module outlet then the operation is termed crossflow and applies to all sidestream systems.

Crossflow implies that, for a single passage of feedwater across the membrane, only a fraction is converted to permeate product. This parameter − the ratio of permeate to feed flow − is termed the ‘conversion’ or ‘recovery’. The recovery is reduced further if product permeate is used for maintaining process operation, usually for membrane cleaning.

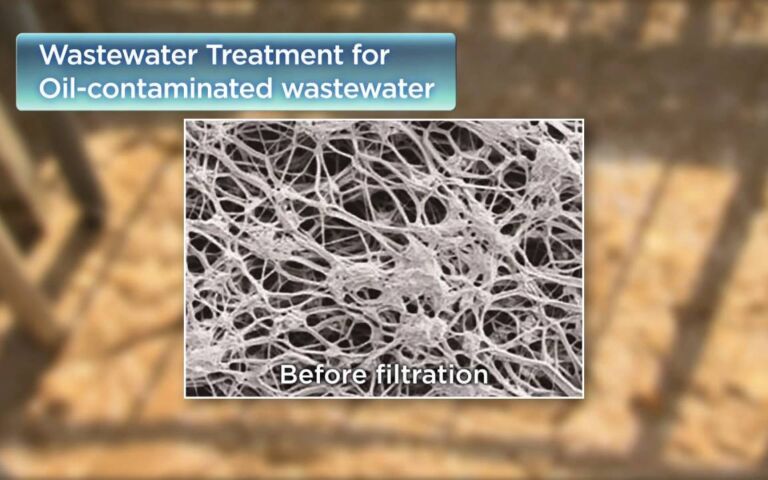

Filtration always leads to an increase in the resistance to flow. In the case of a dead-end filtration process, the resistance increases according to the thickness of the cake formed on the membrane, which would be expected to be roughly proportional to the total volume of filtrate passed. Rapid permeability decay then results, at a rate proportional to the solids concentration and flux (which combine to give the solids loading, demanding periodic cleaning − see Solids loading in MBRs – a load off your mind …?).

For crossflow processes, this deposition continues until the adhesive forces binding the cake to the membrane are balanced by the scouring force (the shear) of the fluid passing over the membrane. This then leads to much slower permeability decline than for dead-end operation, meaning that cleaning is required less frequently.