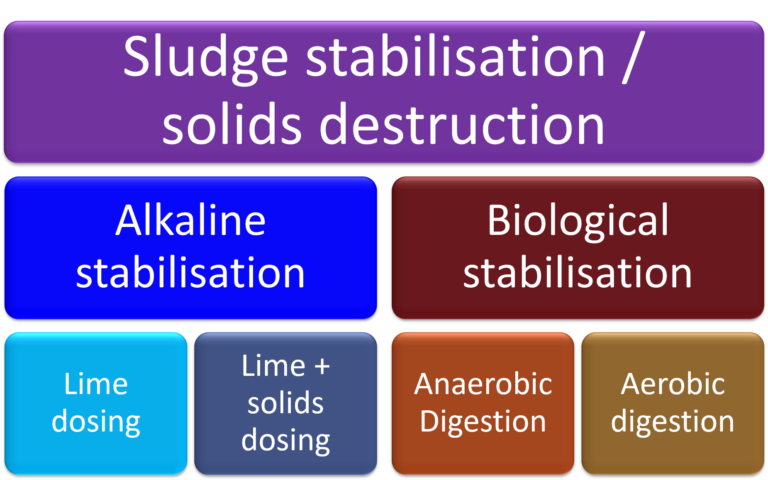

About sludge stabilisation

Sludge stabilisation processes are those which reduce its odour and putrescence and its level of pathogenic organisms. This is generally achieved either chemically or biologically.

For alkaline stabilisation, a basic chemical reagent such as lime − sometimes supplemented with a granular or powdered solid − is dosed into the sludge. Biological stabilisation uses micro-organisms which develop naturally within the sludge under the reactor conditions to biochemically degrade the organic material.