Membrane separation process configurations in MBRs

MBR process configurations

MBR membranes can be designed as two process configurations:

- immersed (iMBRs) and

- sidestream (sMBRs).

The immersed configuration is also sometimes referred to as ‘submerged’ or ‘internal’.

Further process configurations using immersed membranes, based on the way in which the membrane is used, include ‘diffusive’ and ‘extractive’. The diffusive membrane forms the basis of the membrane aerated biofilm reactor (MABR). The extractive MBR system has not reached the stage of commercialisation.

Almost all current commercial MBRs other than the MABRs employ a membrane solely for retaining the sludge in the bioreactor whilst producing a high-quality permeate product.

Membrane bioreactor configurations

The first membrane bioreactors developed in the late 1960s were based on the sidestream configuration. For this configuration, the membrane system is placed outside the biological treatment process tank. The sludge is then pumped through the membranes in ‘crossflow’ mode, normally at an elevated pressure (2−3 bar), and the permeate forced through the membrane under the combined action of the pressure and the crossflow. The unpermeated stream is then returned to the biotank.

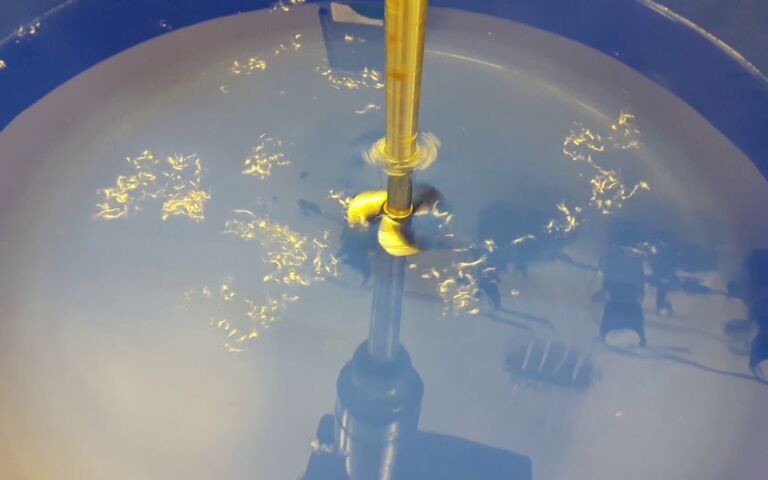

For the more recent immersed configuration, introduced in the early 1990s, the membrane is placed in the biotank and scoured with air introduced by an aerator placed beneath or within the membrane module.

As with almost all membrane separation processes, key to sustaining the flow of water through the membrane is the generation of ‘shear’. This relates to the flow of fluid over the membrane surface, which, for sidestream configurations, is sustained by the flow of sludge and for immersed systems by the action of the air bubbles.

Sidestream configurations are sometimes termed 'external'.