Membrane bioreactors − flat sheet configurations

About flat sheet configurations

Flat sheet (FS) membranes are one of the three types of membrane technology configuration.

FS membranes have planar configuration and are predominantly rectangular. They are designed to be immersed in the membrane tank, and scoured with air to maintain the flow of sludge through the membrane channels.

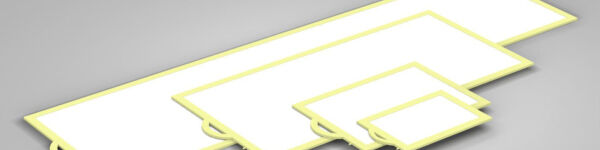

The element may be referred to as a ‘sheet’, ‘cartridge’ or, most commonly, a ‘panel’. The panels can either be rigid/semi-rigid or flexible, the flexible panels being thinner.

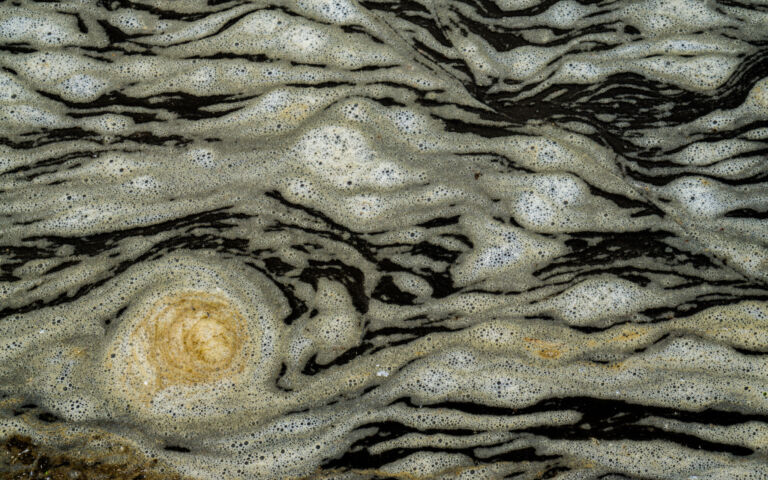

Rigid panels have a 4−6 mm-thick plastic backing plate to which the membrane’s edge is welded on both sides. The membrane is separated from the rigid backing plate by a thin spacer. Water flows from outside to inside the panel through the spacer material and the permeate collected either from the permeate outlet tube(s). The panels are loaded into a ‘cassette’ which holds a large number (50−200) panels, the permeate outlet tubes of which are connected to one or two manifolds.

The flexible panels comprise a single piece of material containing both the membrane and the spacer material, and as such are sometimes described as ‘composite’ membranes. For these materials the spacer is only 2−3 mm thick. The permeate is collected from either the centre of the side(s) of the panel, rather than from individual permeate outlet tubes for each panel.

For all FS products the sludge is air-lifted up through the membrane channels by air bubbles provided from a coarse-bubble aerator placed underneath the module.

Modules (ie collections of elements) may be stacked to provide a double deck, with further stacking possible for a few products.

Flat sheet membranes are used almost exclusively for immersed MBRs for both industrial and municipal applications, where they are sometimes favoured for smaller installations on the basis of their operational simplicity.

Examples of reference installations using flat sheet configurations include Swanage STP and Al Ansab STP.