Biotreatment process configurations in membrane bioreactors

Aerobic, anoxic and anaerobic treatment

The contaminant removal achieved by any biological process is dependent on whether oxygen is present, and in what form. Aerobic processes require dissolved oxygen to convert organic carbon to carbon dioxide and ammonia to nitrate (nitrification). These both represent biochemical oxidative ‘aerobic’ processes.

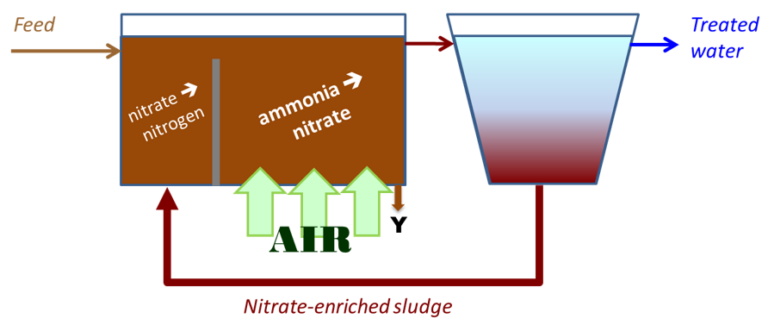

In the absence of dissolved oxygen, organic carbon may still be oxidised if an alternative source of oxygen is present − from an oxyanion and specifically from nitrate (NO3-). This then presents a means of removing nitrate, a nutrient, from the wastewater.

Nitrate formed from nitrification of ammonia can be converted to nitrogen gas by biochemical reaction with organic carbon, a process known as ‘denitrification’. This can only take place if dissolved oxygen is absent but nitrate is present − conditions described as ‘anoxic’.

Returning the treated nitrate-rich sludge to an anoxic zone in front of the aerobic treatment step thus allows the nitrate to be removed, a process modification known as the ‘Modified Ludzack-Ettinger’ (MLE) process. A combination of aerobic nitrification and anoxic denitrification permits most of the ‘total nitrogen’ (TN) to be removed.

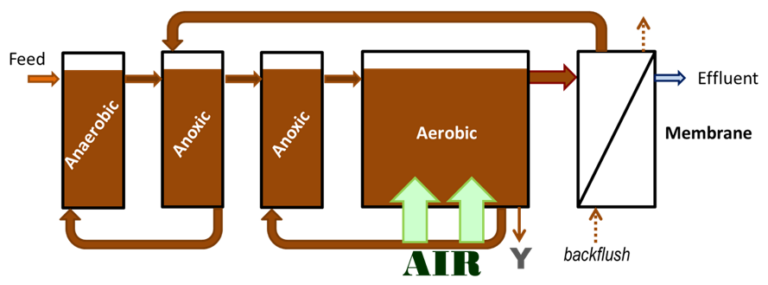

If there is no source of oxygen to allow any biochemical reaction with the organic carbon to take place − either from oxygen or oxyanions − then the conditions are described as ‘anaerobic’. In the treatment of municipal wastewater, anaerobic conditions are applied as a treatment step in assisting the removal of phosphate from the water.

Biological phosphorus removal (BPR) in this manner proceeds through recirculation of the sludge to an anaerobic zone. This promotes phosphate removal in two ways:

- by encouraging the phosphate to be taken by the biomass (the microbiologically active component of the sludge), and

- releasing the biological phosphate as inorganic phosphate, which can then be removed by chemical precipitation.

Anaerobic treatment may also be used to remove organic carbon from effluents. The organic carbon is then substantially converted to methane rather than carbon dioxide, providing an energy source. Anaerobic processes also demand no aeration - a significant contributor to the process energy consumption. However, the biokinetics are significantly slower than aerobic processes, demanding much larger tanks and thus incurring a higher capital cost than the aerobic equivalent.