Solids loading in MBRs – a load off your mind …?

Simon Judd has over 35 years’ post-doctorate experience in all aspects of water and wastewater treatment technology, both in academic and industrial R&D. He has (co-)authored six book titles and over 200 peer-reviewed publications in water and wastewater treatment.

Probably the greatest enigma of immersed membrane bioreactors (iMBRs) is the fact that they work at all. This might sound a little flippant: most iMBRs certainly operate pretty well most of the time under the appropriate conditions.

And those conditions are, for the treatment of regular municipal wastewater by an immersed hollow fibre (iHF) membrane, around 25 litres per h per m2 membrane area (LMH) and a mixed liquor suspended solids (MLSS) concentration of 10−12 g/L.

Membrane scouring is normally about 0.2−0.4 Nm3/h air flow per m2 membrane area, which means that about 10−15 L air is needed for every litre of permeate. The mixed liquor is transferred between the biological tank and the membrane tank at a rate of 4−5 times the permeate flow, such that the mean solids concentration in the membrane tank is 20−25% higher than that of the biological process tank.

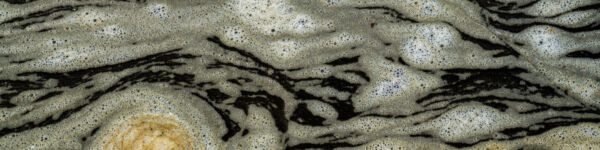

But here’s the thing. The above numbers imply that the rate at which the solids arrive at the membrane surface (i.e. the solids loading) is around 250 g per h per m2 membrane area. That’s six kilograms of nasty, sticky, squidgy solids hitting each square metre of membrane surface every day.

It’s instructive to compare this to potable water membranes used for direct filtration (i.e. coagulant dosing followed by membrane filtration without intermediate clarification using a media filter, DAF or some-such). There are a number of such plants installed in the UK and elsewhere around the world, normally treating surface waters, and it is not unknown for them to clog in pretty much the same way as MBRs.

At this point, it’s necessary to defer to the extensive experience, broader knowledge and higher intelligence of Nic Booker, who has worked in potable water membrane filtration for longer than either he or I care to remember, or admit. According to Nic, anecdotal evidence from some of the UK installations suggests that clogging issues arise at well below 1 g per h per m2. At higher loading rates the normal backwash and cleaning protocols appear to be insufficient to sustain operation without solids accumulating in the fibre bundle. This is with regular backflushing at an appropriate flux and duration.

System hydrodynamics

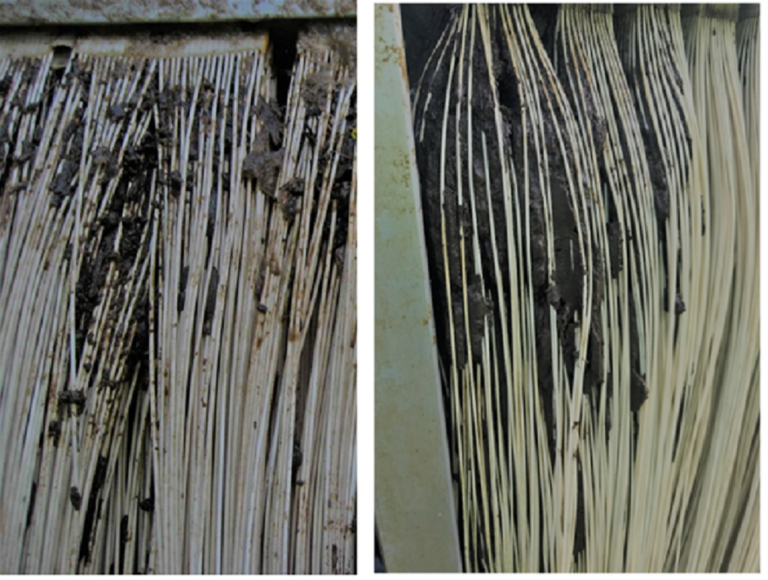

So, why is this? The solids don’t significantly differ physically between the two applications: they are both flocculant in nature and so are predominantly water with organic matter and a little inorganic material. The clogged solids actually look very similar in the fibre bundle. The membrane technology doesn’t greatly differ in the case of the immersed systems; at least two technology suppliers offer the same membrane fibre for both potable water and MBR applications. And yet there is apparently a two orders of magnitude difference in the sustainable solids loading between the two applications.

The answer would appear to be down to the system hydrodynamics. The potable water membranes operate at a higher flux – perhaps around 40 LMH or more – and, in most cases, limited or zero controlled crossflow. Immersed MBRs, on the other hand, operate at 20−25 LMH and sufficient air scour to apparently clear the solids from the fibre bundle (or, in the case of the flat sheet configuration, from the membrane parallel flow channel).

So it is the ratio of the crossflow, and the associated shear forces, provided by the air scour to the flux which is critical. There is still a solids loading threshold: according to Zsirai et al (2014) things start to go pear-shaped at around 18 g/L MLSS. However, increasing the aeration rate and reducing the flux can again produce sustainable operation (which is why there are membrane thickeners for MBR sludge using exactly the same technology as that of the iMBR).

The importance of the air scour will be apparent to anyone unfortunate enough to have suffered a blower power failure or clogged aerator in an iMBR. Those six kg/m2 per day of solids really do end up on the membranes, and it probably doesn’t even take a day for this to have a profound impact on the permeability.

So, rest easy. All is well, as long as those pesky solids can be shifted away from the membranes. Just don’t switch off the blowers.