Applications of membrane bioreactors in wastewater treatment

When would you use an MBR?

It is generally recognised that MBRs become an attractive treatment option when:

- space is limited, and/or

- a high treated water quality is required (for example for water reuse).

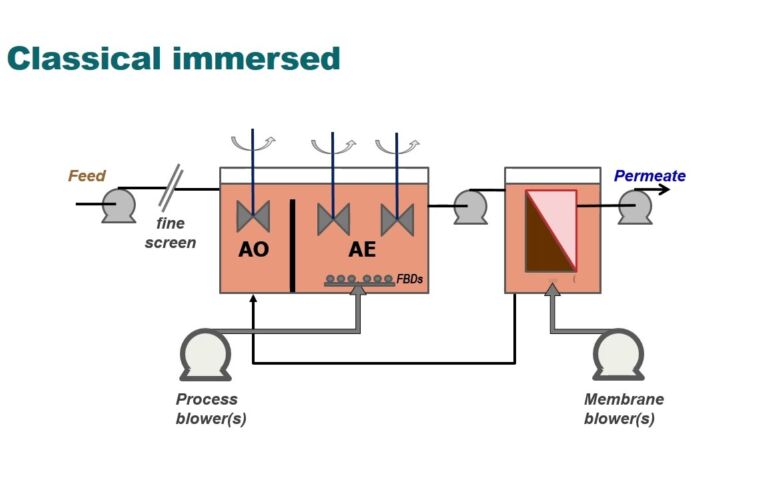

In the past, the relatively high cost of MBRs compared with the classical ASP meant that membrane bioreactors were generally employed for relatively small flows.

However, increasingly stringent environmental legislation coupled with decreasing capital (specifically membrane) and operating (primarily energy) costs have meant that MBR installations steadily increased in size over the course of the first 20 years of their implementation. There are now a substantial number of municipal MBR plants over 100 megalitres/day (MLD) in peak daily flow (PDF) capacity.

MBRs have been implemented across a number of industrial sectors. Not surprisingly, wastewaters most conducive to treatment by MBR technology are those with a readily biodegradable organic carbon content.

The food and beverage sector has seen extensive take-up of MBR technologies − both for sidestream and immersed configurations. However, wastewaters which are highly recalcitrant (i.e. sparingly biodegradable) have also been successfully targeted for treatment by MBRs since the long solid retention times attainable allow more effective biological treatment than that achieved by conventional biological processes. These include landfill leachate and pharmaceutical effluents.

On the other hand, waters containing free (i.e. suspended) oil − either vegetable or mineral in derivation − are somewhat more challenging since membranes are extensively fouled by such materials. In such cases, pretreatment − either by plate separation, dissolved air flotation or both − is required to protect the membrane.