Media processes − overview

Media/fixed-film processes

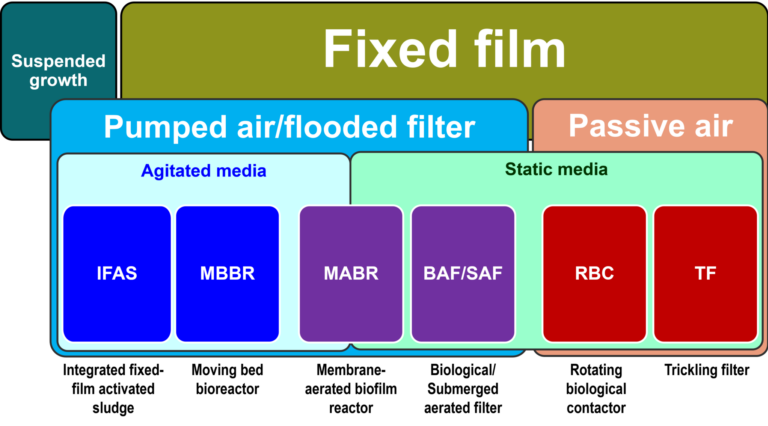

Media processes are those which use materials, sometimes called ‘carriers’, which provide a large surface area onto which biofilms can form. The microorganisms are fixed to a solid surface, rather than being suspended in the wastewater as with the activated sludge processes which include MBRs. Media processes are more generally referred to as 'fixed film'.

The different configurations of the principal fixed-film processes are summarised below. There are essentially two modes of liquid:air contacting (passive or pumped), and two states of media (static or agitated).

| Process | Description |

|---|---|

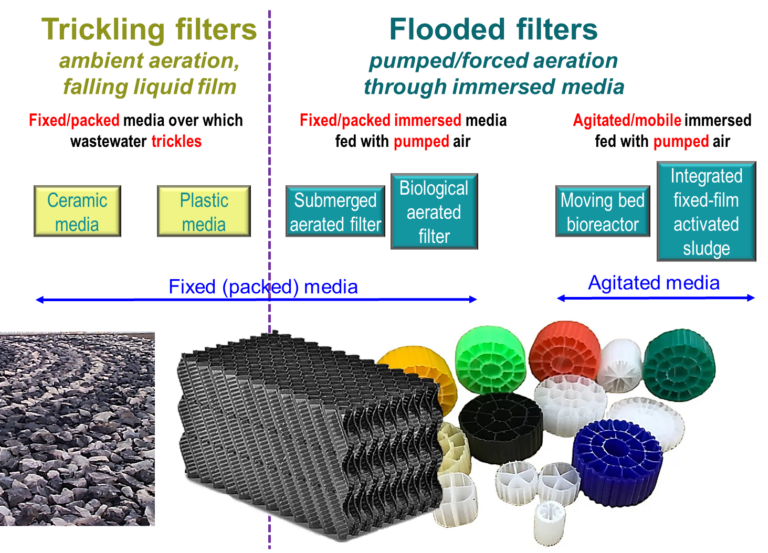

| TF | Operates by allowing the wastewater to trickle over the surface of a fixed media bed. The biofilm attached to the media is sustained by contact with both the wastewater organics and ambient oxygen in the air, with no air pumping required. A small amount of mechanical energy is required for rotating the arms distributing the wastewater over the media. |

| RBC | Operates by forming the biofilm on a series of large slowly-rotating discs which are partially immersed in a trough containing the wastewater. In the course of one rotation the biofilm is in contact with both air-bound oxygen and the organics-laden wastewater. No air pumping is required. A small amount of mechanical energy is required for rotating the discs. |

| BAF/SAF | Operates by immersing structured media as a fixed bed through which the wastewater passes. The biofilm formed on the media is sustained by the organics in the wastewater passing through the bed and the dissolved oxygen (DO). Air pumping is required for maintaining a level of DO. |

| MABR | Operates using a gas-permeable membrane both as an aerator and as the support for the biofilm. The oxygen from the air passing through the membrane passes directly into the biofilm without having to dissolve in the water, as with all other fixed-film processes. The oxygen utilisation efficiency is therefore extremely high, decreasing the aeration energy consumption. |

| MBBR | Operates by immersing loose media in a tank through which the wastewater passes. The biofilm formed on the media is sustained by the organics in the wastewater passing through the bed and the DO. Air pumping is required for both maintaining a level of DO and agitating the media. |

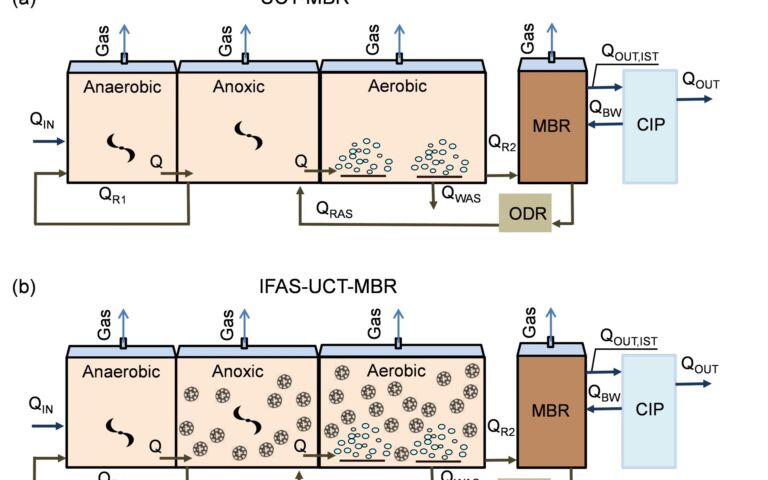

| IFAS | Operates in the same way as the CAS but with media added to the process biological tank to promote biological activity by increasing the surface area of the biofilm. |

Flooded media require bubbling with air to sustain the supply of dissolved oxygen to the biofilm since, in these cases (BAF/SAF, MABR, MBBR and IFAS), the media and attached biofilm are submerged in water. This then incurs an energy penalty associated with aeration – similar to the suspended growth processes.

For passive aeration of the TF and RBC, the biofilm is in intermittent contact with ambient air, achieved by mechanical means. These two processes are lower in energy demand than the flooded media processes because they avoid the requirement to pump air. The RBC uses a slowly rotating disc to achieve ambient aeration; it has closer similarities to the trickling filter than the MBBR or IFAS.

For all fixed film processes the biofilm thickness has to be controlled. An overly thick biofilm has two key adverse effects:

- the biofilm can become anaerobic at the media:biofilm interface, adversely affecting the system microbial ecology and biochemistry, and

- the flow of water through the channels can be impeded, leading to heterogeneous flow, pressure losses and general loss of performance.

Media materials

Both polymeric and ceramic media are used in fixed film processes. For agitated media processes the media must usually be close to being neutrally buoyant to allow them to be agitated by the air bubbles.

In the case of static media processes (BAF/SAF, TF and some of the MABR technologies) the media can be either a continuous 3D structure or individual discrete pieces of material which are packed in place. They may then be agitated for cleaning purposes, as is the case for the BAF during backwashing.

For both the MBBR and IFAS processes the media are agitated by the air bubbles delivered to the bioreactor. In these cases the media must be of a weight which permits them to be distributed throughout the reactor mixed liquor while being aerated.