Hybrid MBR processes

Hybrid MBR processes are those which combine the conventional MBR technology with some other process. Examples of hybridisation include:

- the addition of media to the biological process tank, and possibly the membrane tank, and

- the use of a dense membrane, such as forward osmosis (FO) or nanofiltration (NF) membrane, in place of the usual ultrafiltration or microfiltration membrane

1. Media-enhanced MBRs

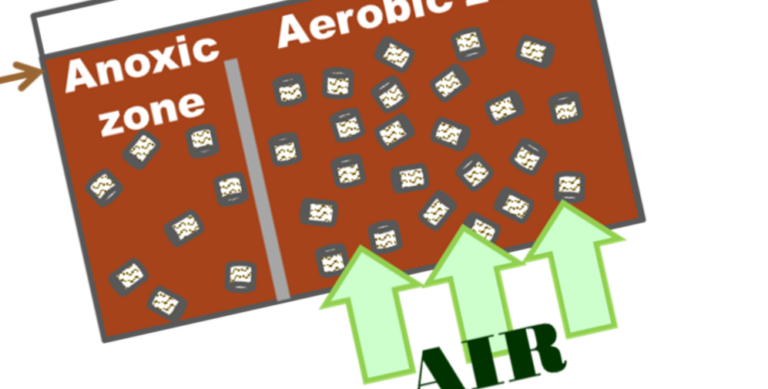

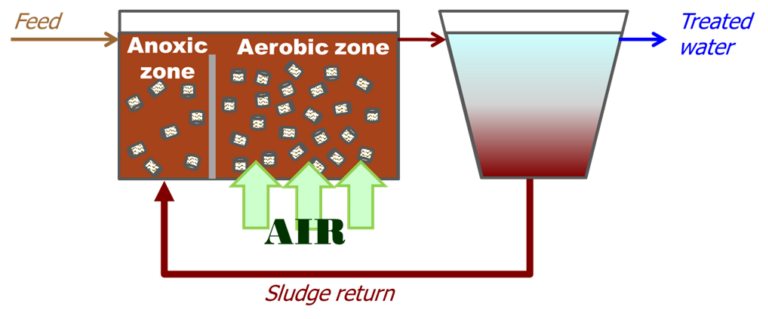

The two main media-based processes which have been coupled with MBRs, as well as with an MABR in the case of one commercial system, are the integrated fixed-film activated sludge (IFAS) process and the moving bed bioreactor (MBBR). These technologies have been in use as discrete advanced biological treatment processes since the early 1990s.

The key difference between the IFAS and the MBBR is that the former has a sludge return line. The MBBR, on the other hand, comprises two sequential tanks without recirculation.

Of the two technologies, the IFAS has been more extensively explored for coupling with an MBR since it is essentially based on the conventional activated sludge (CAS) process. It is unclear as to whether the addition of the media to the MBR provides significant fouling suppression, though there is some evidence of improved nutrient removal.

2. Dense membrane MBRs

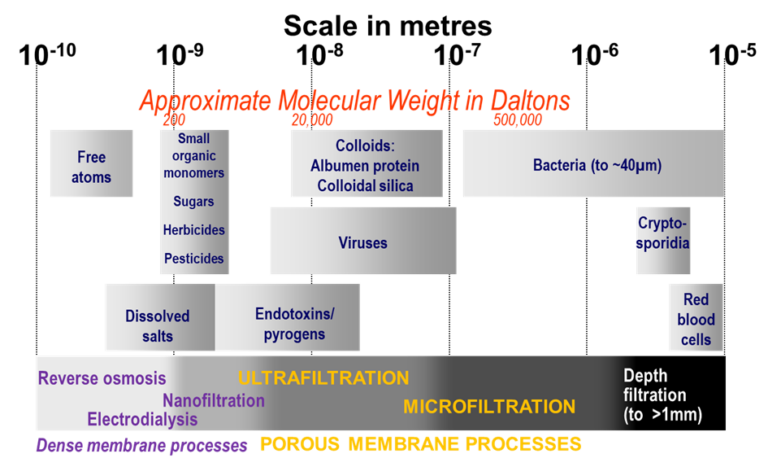

MBRs are conventionally fitted with ultrafiltration (UF) or microfiltration (MF) membranes, otherwise known as ‘porous’ membranes. Porous membranes are capable of rejecting particulate matter and most pathogens in the water, but not dissolved species such as pharmaceuticals and contaminants of emerging concern (CECs), collectively referred to as ‘micropollutants’, or ions. If the micropollutants are neither biodegraded nor associated with the sludge then, in a conventional MBR, they are likely to pass into the permeate product.

Dense membranes are those are capable of rejecting ions or other dissolved charged species. They are used in reverse osmosis (RO), nanofiltration (NF), electrodialysis (ED) and forward osmosis (FO) processes, where the latter two are extractive rather than filtration processes and are much less extensively employed.

The fitting of MBRs with dense membranes is a recent development and is yet to be implemented. The resulting hybrid processes, specifically MBR/NF and MBR/FO, aim to achieve biological treatment and (partial) desalination in a single step. The MBR/FO hybrid is referred to as an ‘osmotic membrane bioreactor (OMBR)’ (see below).

Whilst hybrid MBR processes can potentially offer simplicity and a reduced footprint, the rejection of ions as well as the particulate matter by the membrane leads to a build up of salinity in the mixed liquor. This has two key potentially negative impacts:

- the generation of a saline waste sludge can affect its processing and disposal, and

- the mixed liquor fouling propensity may increase due to the generation of extracellular polymeric substances (EPS).

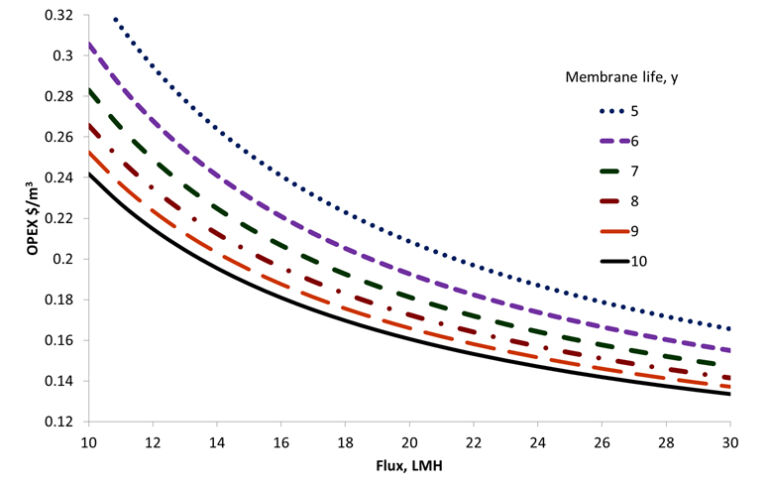

Of greater significance than the above, however, is the much reduced permeability of the dense membrane challenged with the MBR mixed liquor compared with water. For example, reported flux values for an NF/MBR are in the region of 10 LMH (Tay et al., 2018). This is around 50−65% of the flux achieved by an RO for a classic two-stage MBR−RO process. The RO also provides a higher-purity permeate than the NF. Given the relatively low cost of the RO membrane and the simplicity of the RO process operation when placed downstream of a conventional MBR it is perhaps unsurprising that the hybrid NF/MBR has not developed beyond bench-scale studies.

3. Osmotic MBRs (OMBRs)

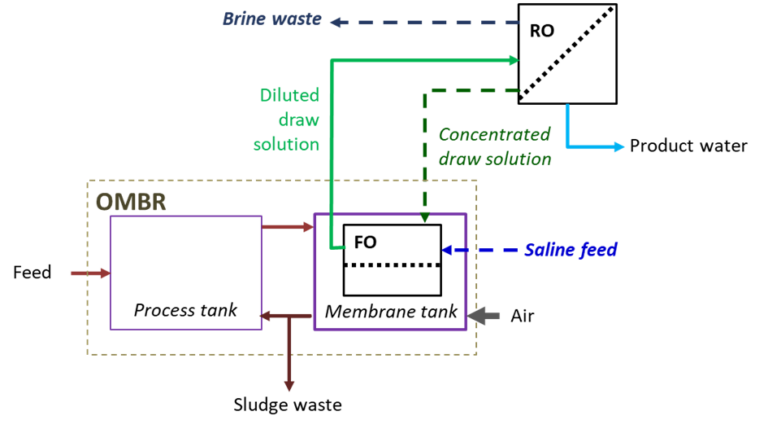

Osmotic MBRs employ forward osmosis (FO) membranes to extract water from the mixed liquor into a ‘draw solution’ on the permeate side of the membrane through the action of osmosis. This is a very low energy process.

The draw solution contains an electrolyte sufficiently high in concentration to generate an osmotic pressure difference between it and the mixed liquor. The extracted water must then be separated from the draw solution through some separation process, the most commonly used being RO. This then incurs a similar energy demand to an RO installed downstream of an MBR in the more conventional MBR−RO process. The OMBR has thus not been implemented for the duty of wastewater reuse specifically.

Whilst the OMBR technology is unlikely to compete with the MBR−RO process for classical wastewater reclamation and reuse duties, it has been demonstrated that it can offer a cost benefit for an ‘open loop’ system (Jalab et al, 2019). This applies when both high-salinity waste brine (from seawater desalination) and low-salinity wastewater streams are available and require processing.

The waste brine forms the draw solution and is diluted by extraction of water from the MBR mixed liquor. The product water is then generated from this stream by permeation through an RO. This system thus makes use of a waste stream (RO brine) to extract the water, avoiding the expense of preparing and recovering a draw solution. It is nonetheless more complicated than the classical two stage MBR−RO process and relies on the close proximity of the RO brine and wastewater streams.