'What are MBRs?' - our new pocketbook

Our new 'What are MBRs?' pocketbook combines print and digital tools and is suitable for newbies and specialists alike. 10% discount only from The MBR Site

Distillery effluent treatment with anerobic MBR technology

Behind the scenes at the Glenmorangie site

Sponsored content

MBR features

Search our in-depth feature articles on MBRs. Practitioners with experience of operating membrane bioreactor technology and academics researching this specialist area share their expertise.

About MBRs

A membrane bioreactor (MBR) is a wastewater treatment process where a perm-selective membrane is integrated with a biological process – a suspended growth bioreactor.

A membrane bioreactor is essentially a version of the conventional activated sludge (CAS) system. Whereas the CAS process uses a secondary clarifier or settlement tank for solid/liquid separation, an MBR uses a membrane. This provides a number of advantages relating to process control and product water quality.

Municipal & industrial treatment

There is no significant difference in the design of the MBR technology for a process treating industrial rather than municipal wastewater. The key differences between the two applications are that, for industrial effluents, there are:

- higher concentrations of organic matter

- more temporal variation in the concentrations of pollutants (seasonally and diurnally)

- very significant variations across different industrial sectors, the most biorefactory effluents being from landfill leachate applications

- no requirement for the removal of pathogenic micro-organisms, unless the effluent is combined with a sewage stream.

Highlights in this section

MBR costs

A full needs analysis is required before selecting a membrane bioreactor system, first of all to confirm that an MBR will be the most cost effective solution for a particular requirement, taking everything into account. Secondly, to ensure an MBR is the most appropriate choice of technology for the circumstances.

Highlights in this section

Design and Operation

Operation and maintenance (O&M) parameters for an MBR include:

- membrane side − flux, pressure, permeability, recovery, membrane aeration rate, and physical and chemical cleaning cycle times and protocols, and

- biological side − hydraulic and solids retention time, and sludge recycle rate(s).

Highlights in this section

Explore more content…

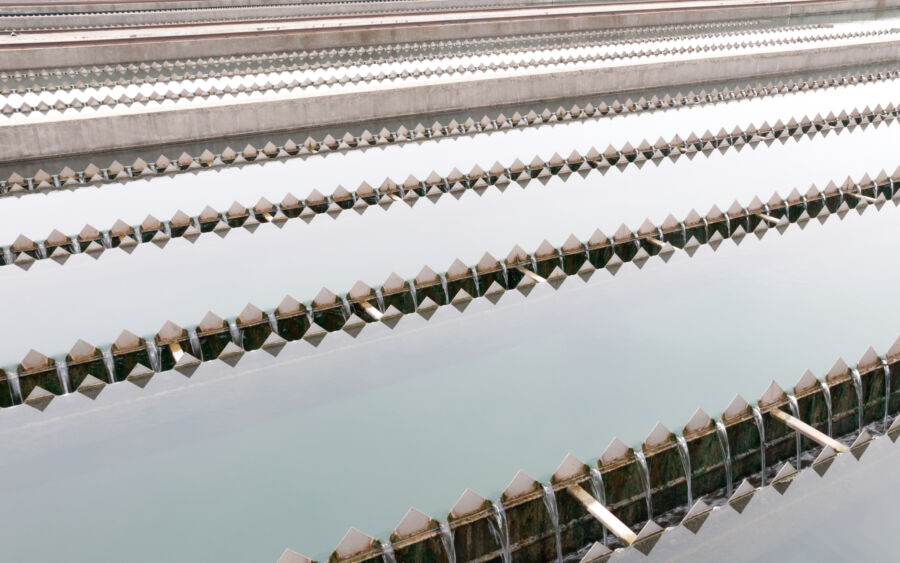

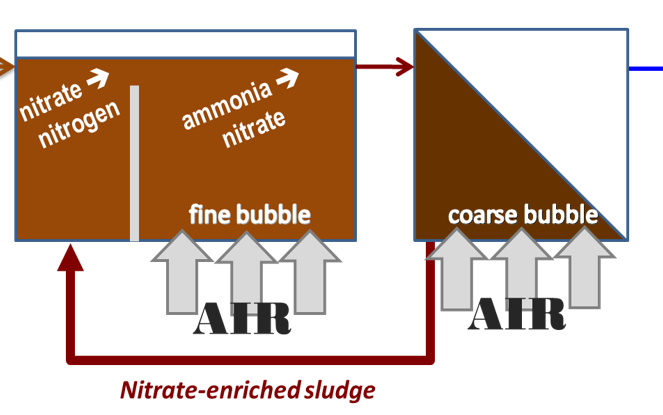

The MABR−MBR demonstration plant at Ulu Pandan, Singapore

Singapore's Integrated Validation Plant project at Ulu Pandan focuses on exploring advanced technologies like MABR and AGS−MBR to achieve process intensification, energy efficiency, and optimized used water treatment processes.

What are MBRs?

If you're new to MBRs, read our introduction to membrane bioreactors - and explore all our MBR Basics pages

Can anaerobic MBRs produce reusable water from sewage?

Yu Huang, Paul Jeffrey and Marc Pidou consider whether anaerobic MBRs and non-potable water reuse are a good match

Comparing MBR technology with the MBBR and CAS: how do the numbers stack up?

Using the Transcend modeling platform to benchmark conventional activated sludge with two alternative process technology options available for wastewater treatment