Microbial fuel cells: something for nothing?

Simon Judd has over 35 years’ post-doctorate experience in all aspects of water and wastewater treatment technology, both in academic and industrial R&D. He has (co-)authored six book titles and over 200 peer-reviewed publications in water and wastewater treatment.

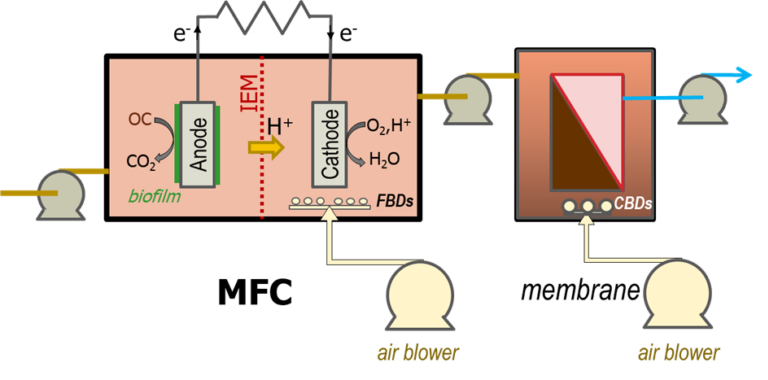

On the face of it, there would seem to be a lot to like about coupling microbial fuel cells (MFCs) with MBRs. When placed in wastewater, MFCs can generate electrical energy by creating an anaerobic region around the anode and an aerobic region around the cathode. If the aerobic cathodic region can be coupled with an immersed membrane separation process − which is naturally aerobic due to the application of an air scour − then you have an MBR with supplementary electrical energy – seemingly provided at no extra cost.

Microbial fuel cells were first conceived in the early 20th century by the botanist (and reverend) Michael Cressé Potter. Their practical application to wastewater treatment, however, only really began in the early 2000s when various research articles on the subject were published.

Coupling MFCs with MBRs is an even more recent development, perhaps dating back no more than 10−12 years. In this time, there have been dozens of studies, most of them reporting the benefits offered by such systems in terms of:

- improved biological treatment (nitrification, organic carbon removal, etc)

- reduced membrane fouling, and

- power density in mW per m2 electrode area.

Different configurations have been tested at bench scale, of varying levels of complexity and incorporating a range of materials. In general, the electrodes have been either carbon-based (graphite rods or particles, activated carbon, carbon felt/cloth/brush) or stainless steel. In some cases, electrically conducting membranes have been developed as the cathode to combine the cell electrode with filtration.

So, how do these systems measure up in terms of improved performance over regular MBRs?

Improved biological treatment may well be measurable but it is perhaps not practically significant. One of the key attributes of MBRs is that they are able to provide very high water quality, both because of the highly effective solid−liquid separation provided by the membrane and the uncoupling of the solid and hydraulic retention times. The latter allows sufficient nitrification and BOD removal for most practical applications without necessitating further enhancement.

Often, the reduced fouling propensity is emphasised as a key output from these MFC−MBR studies. But fouling is not a major limitation on efficient MBR operation for municipal wastewaters, in contrast with clogging. And if fouling reduction is the main benefit, then it is debatable that implementing an MFC will be more cost effective than alternative options such as chemical dosing, quorum quenching or simply installing more membranes.

Which leaves the electrical power generation element of the process – a truly ingenious and novel attribute. The power density can be translated to specific energy consumption (SEC) in kWh per m3 treated water, although few authors appear to report this more practically relevant metric. Those that do indicate that the SEC produced is somewhere in the region of 0.002−0.05 kWh/m3. This compares with a SEC of 0.5−1 kWh/m3 normally associated with MBR treatment of municipal wastewater, based on a modern, optimised system.

And therein lies the rub. It is debatable whether the energy benefit offered by MFC−MBR systems is significant enough to offset the costs associated with the MFC system itself. It’s also uncertain as to whether the energy benefits are sustainable for real wastewaters under conditions of extended operation. Current research literature seems to be based largely on limited-term practical tests conducted at bench-scale, and much is based on analogue feedwaters. There doesn’t appear to have been an extended pilot trial with a representative municipal wastewater feed.

It’s unclear whether there has ever been any cost or life cycle analysis of these systems. There doesn’t seem to have been any report that considers the actual capital cost (or embedded carbon, in the case of life cycle analysis) associated with either implementing a complete MFC−MBR system or retrofitting an MFC to an existing MBR. And yet there must be a cost associated with the materials used for the electrode, the creation of an anaerobic zone and, if required, adaptation of the membrane separation component itself.

The MFC−MBR technology is ingenious, fascinating and offers potential for low-energy wastewater treatment. But it is currently unclear how much latent electrical energy can be recovered from the wastewater, and what the cost is of retrofitting the electrodes and other components of the MFC to existing MBR installations. It would be a simple enough task to compare the present value of the energy saved over the life of the installation to the capital cost of fitting the MFC.

There are, of course, many examples in the research literature of novel developments which have been extensively explored at bench scale without too much consideration of the practicalities. But this technology offers a perfect example of where some pragmatic, applied research could add real value – by conducting a simple cost benefit analysis comparing MFC implementation with a regular MBR.

It may seem pedantic, but surely no-one buys anything without knowing how much it costs.