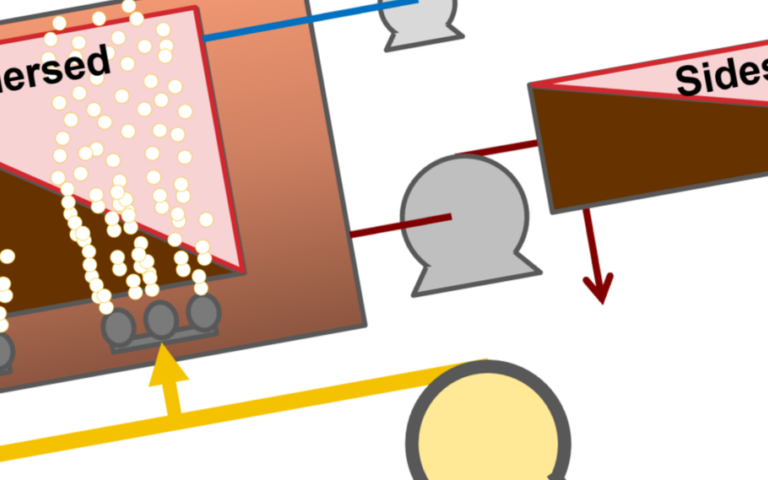

MBR membrane configurations − an overview

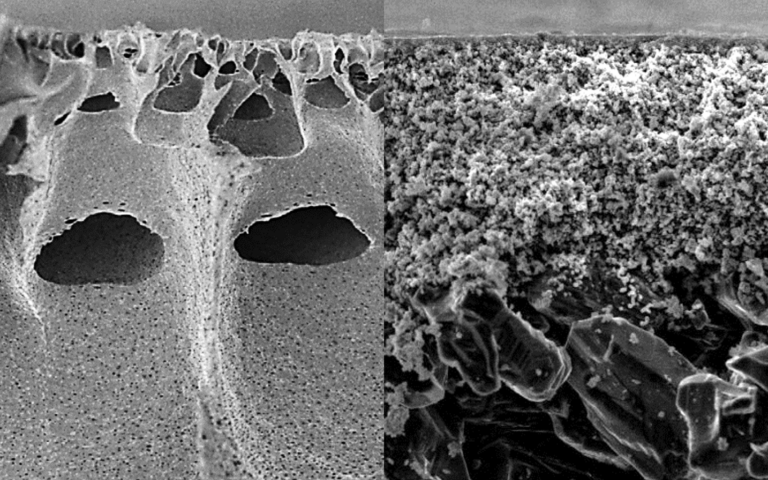

Flat sheet and hollow fibre membranes are used almost exclusively in immersed MBRs for both municipal and industrial applications. Multitube and multichannel systems tend to be used for treating smaller flows of more highly concentrated industrial effluents.