Membrane ageing – factors determining membrane replacement

Simon Judd has over 35 years’ post-doctorate experience in all aspects of water and wastewater treatment technology, both in academic and industrial R&D. He has (co-)authored six book titles and over 200 peer-reviewed publications in water and wastewater treatment.

It’s widely believed that membrane replacement represents the second largest contribution to the operating cost of an MBR or UF/MF filtration plant after energy demand. In reality, it’s probably the third largest in most cases, but we’ll deal that some other time.

There is little doubt, though, that membrane life is of keen interest to membrane technology practitioners. Budgeting for membrane replacement is a thorny issue: renewing the membranes for an entire installation is a tad more pricey than just getting in another couple of IBCs of hypochlorite for membrane cleaning. Many municipalities capitalise membrane replacement cost, i.e. include it as an item in the original investment costs, which demands that its timing is predicted with reasonable accuracy.

Sadly, membrane life is not something that can be easily investigated within the constraints of a standard three-year PhD programme and, as a result, relatively few studies of this topic exist. However, one way of determining membrane life is to trawl through the suppliers’ data on membrane renewal for actual sites. This was the approach taken by Côté et al (2012) for a single membrane supplier of MBR membranes, and it provided some useful and encouraging insights in suggesting a projected membrane life in excess of eight years. Given that this work is now eight years old it would be most illuminating to get an update.

As far as more conventionally scientific papers are concerned, there have been a few studies based on accelerated degradation of membranes by oxidative chemicals (Causserand et al, 2015; Zhang et al, 2017; Fu and Zhang, 2019). These have attempted to ascertain the impacts of chemical cleaning on membrane structure, chemistry (primarily through spectroscopic analysis) and/or mechanical strength. There have also been mechanical strength measurements of membranes sampled from operational sites, such as Ayala et al, 2011 for flat sheet MBR membranes. While these have all indicated and, in some cases, quantified the extent of performance deterioration, not many have come up both with a reasonable estimation of membrane life and the factor(s) which determine it.

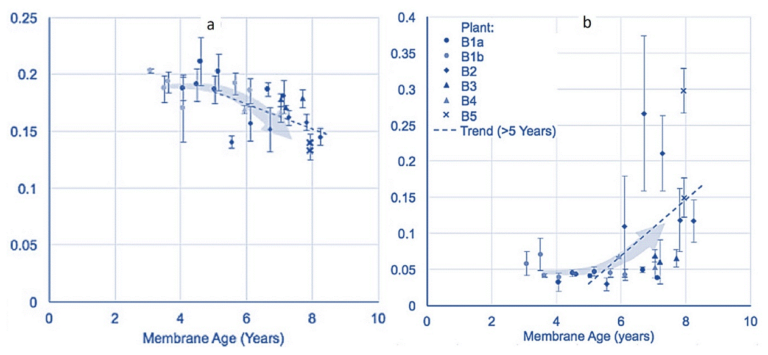

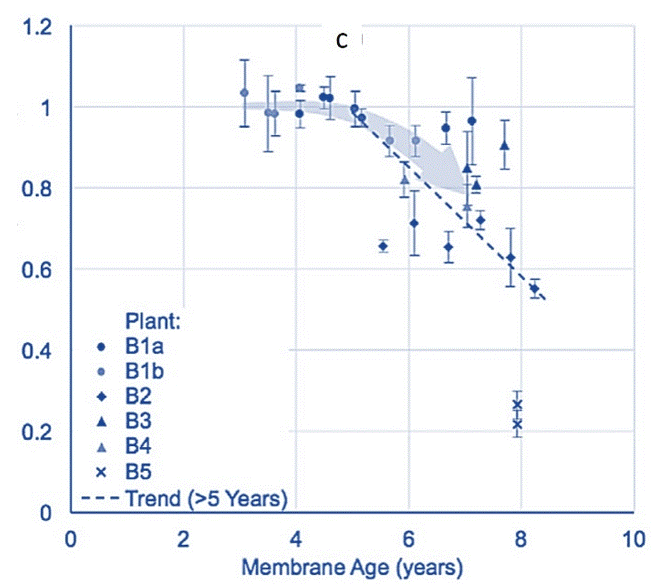

Which is why the recent work carried out at the University of British Columbia by Shona Robinson under the watchful stewardship of Pierre Bérubé is of particular interest. These investigators conducted both mechanical strength (Fig. 1, top left) and fouling rate (Fig. 1, top right) measurements on membrane fibres sampled from various potable water installations, all based on the same membrane material (Robinson and Bérubé, 2020). They discovered membrane permeability starts to decline after around five years or so of practical use, and that this threshold loosely correlates with the loss of some unspecified hydrophilic additive from the membrane (Fig. 1, bottom).

This work to some extent corroborates the earlier findings of Mavukkandy et al (2016) and Causserand et al (2015), who both found the leaching or degradation of the pore-forming additive polyvinyl pyrrolidone (PVP) to impact on membrane permeability. However, most crucially, Robinson and Bérubé’s work has revealed roughly how long it takes for the additive to start to disappear from the membrane surface in practice and subsequently affect permeability.

It seems that, as a result of the loss of the additive, the membranes reach a period of what the authors refer to as 'middle age' – between five and eight years – where their performance declines and becomes noticeably lower than that measured for the first five years of operation. So, as is the case for the rest of us, middle age appears not to treat membranes too kindly. And although the membrane is still very much usable after this period, the permeability is reduced and the fouling propensity greater.

Although their work was based on drinking water, it is reasonable to suppose that the same phenomenon arises in MBRs – although the timings and quantitative impacts may differ. Whether this can then be used to inform both membrane cleaning protocols and membrane manufacture remains to be seen, but it is certainly a step in the right direction.