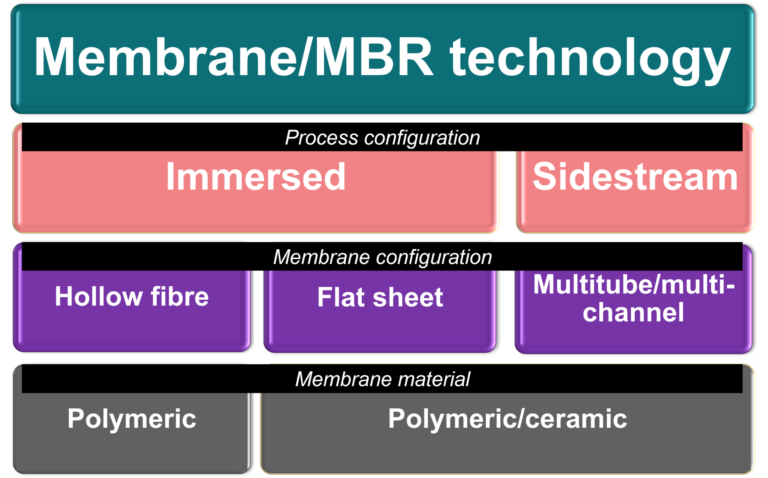

Process and membrane configurations

The word 'configuration' as applied to an MBR can refer to:

- the membrane module, or

- the process.

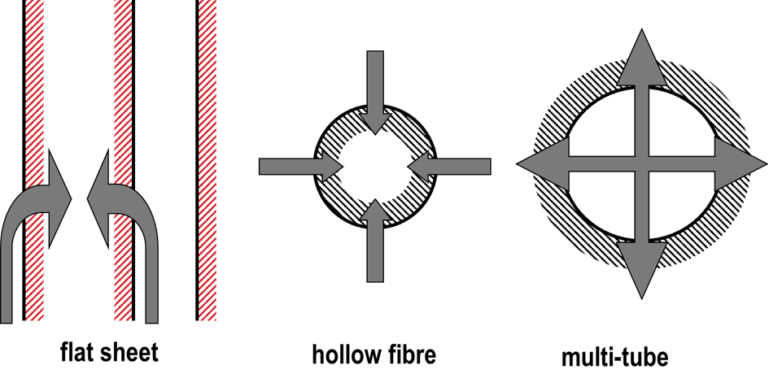

MBR membrane modules are generally grouped into three module configurations:

- flat sheet (FS)

- hollow fibre (HF) and

- multitube/multichannel (MT/MC).

The configuration defines both the membrane geometry and the direction of the flow, which may be either inside to out (for the FS and MT/MC) or vice versa (for the HF). For the HF and MT the inside of the channel is referred to as the 'lumen side' and the outside as 'shell side'.

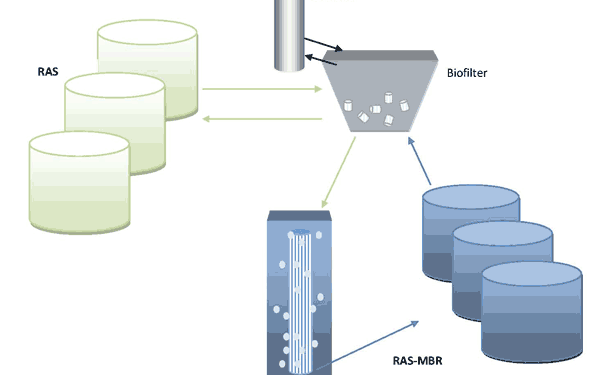

The MBR process configuration refers to way in which the membrane is associated with the biological treatment. There are generally two process configurations:

- immersed (denoted iMBR) and

- sidestream (denoted sMBR).

The immersed configuration is also referred to as 'submerged'.

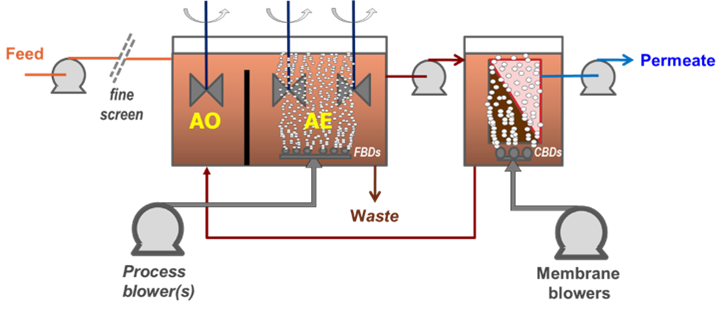

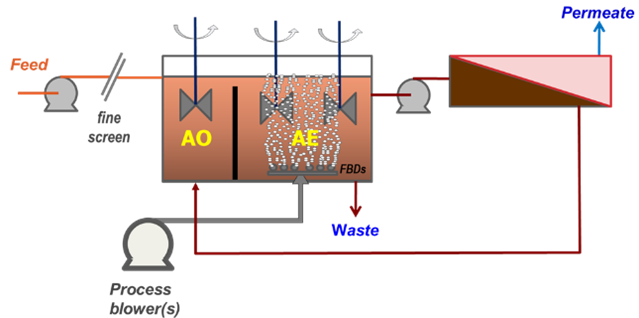

The immersed configuration is characterised by a membrane immersed in its own tank, scoured by coarse bubble diffusers (CBDs) delivering large air bubbles to scour the membrane surface. The sidestream membrane is fed by a pump which directs the mixed liquor through the membrane channels at a relatively high pressure and crossflow velocity.

In general, the FS and HF modules are employed in immersed systems. As such, they can be denoted ‘iFS’ and ‘iHF’ respectively. Sidestream systems generally employ MT modules (hence ‘sMT’).