Membrane technology in controlling micropollutants and pathogens

The challenge posed by micropollutants and pathogens has been the subject of considerable interest over the past few decades. We hosted a free online discussion event, attended by 30 people from across the world, on 14 April 2021 to assess the current status. Read our full report on 'Discussing membrane technology: micropollutants and pathogens' below.

The discussion was hosted by Graeme Pearce (left) of Membrane Consultancy Associates and Simon Judd of Judd Water and Wastewater Consultants, who between them have well over 50 years of experience in membrane process technology as relating to water and wastewater treatment.

Watch the full discussion at:

Discussing membrane technology: micropollutants and pathogens

Initial introduction by Graeme Pearce

In his opening synopsis, Graeme Pearce introduced the three key themes of pathogenic bacteria and viruses, perfluoroalkyl substances (PFAS) and microplastics, discussed in chronological order with regards to their initial entry into the public consciousness.

Graeme noted that process technologies for pathogen control are essentially mature, including methods for testing their integrity (such as pressure decay tests for hollow fibre membranes) and, in the case of these HF membranes, their subsequent repair when required. Membrane implementation for pathogen rejection was driven by legislation introduced in the 1990s. However, as subsequently noted in the discussion, the performance of membrane technology in terms of pathogen rejection − in reuse applications in particular – is still subject to some debate.

Graeme outlined the status of PFAS, which represents a major sub-category within the persistent mobile toxic compounds group of organic micropollutants − or trace organic chemicals (TROCs). There are over 7,000 PFAS chemical types, and they (along with other high-profile TROCs) have been recognised as posing a significant health threat − even at very low concentrations − since the early 2000s. They are not substantially biodegradable, with some having half-lives of hundreds of years, and can only be removed by adsorption or reverse osmosis. Despite being ubiquitous in the environment, with some being discovered seven miles down in the deepest oceans, legislation and implementation of removal technologies are still in their infancy.

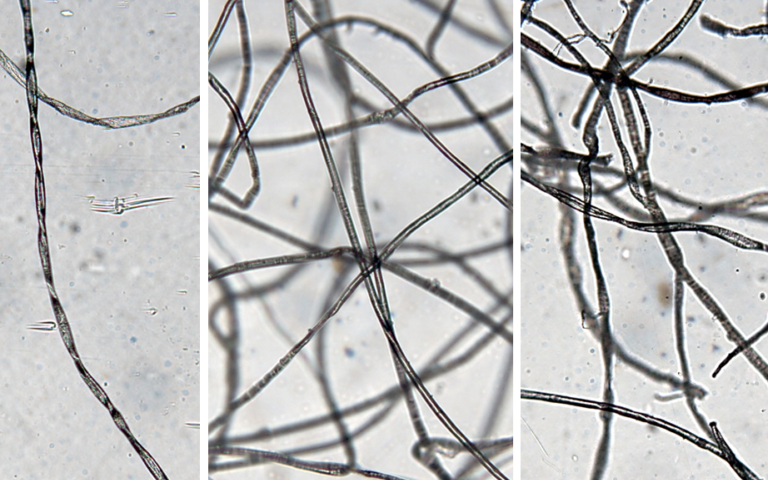

Finally, Graeme discussed microplastics. These are either breakdown products from plastics or fibrous material from textiles, and are typically greater than 0.1 µm in size. Their toxicity and long-term impacts are yet to be fully appreciated, though some evidence exists of reduction of fertility in marine life and increased mortality of earthworms. They are readily removed by membrane filtration (ultrafiltration or microfiltration) but, as with any other membrane process, the concentrated waste stream generated requires further treatment to eliminate these substances completely.

PFAS

Simon Judd pointed out that PFAS in wastewater treatment processes can be expected to be largely associated with the sludge (as with viruses). They do not appear to be significantly degraded by either anaerobic digestion or even the newer hydrothermal processes, but have been shown to be largely destroyed by incineration at elevated temperatures.

Graeme advocated the combination of advanced catalytic oxidation with membrane technology to achieve effective breakdown of PFAS, pointing out that it is the kinetic barrier to the destruction of the chemicals which poses the greatest challenge. It was acknowledged, however, that membrane catalytic processes have been researched for many years – dating back to the 1990s or earlier – without any significant implementation of these technologies.

A very informative contribution was made by Jochen Kallenberg of Dryden Aqua. Jochen pointed out that Switzerland has already implemented regulation, following a joint working group with Germany. The regulation is very pragmatic, being based on 24 target chemicals (as opposed to >300 as apparently being considered by German regulators), in municipal wastewater with required removal stipulated as either 60% or 80%. Polishing with activated carbon either individually or in combination with ozone is recommended for this. Granular activated carbon (GAC) has been shown to successfully achieve the required treated levels of PFAS, with operating cycles of at least two months between regeneration. An alternative is to dose powdered activated carbon (PAC) into the return activated sludge (RAS) line, but this then obviously adds to the solids waste.

Steve Katz (Suez) observed that PAC added to the MBR process has been shown to be effective for removal of trace organics, by retaining them in the bioreactor for degradation. Oxidants in combination with PAC may also be effective, with downstream membrane clarification. It was commented that abrasion of the membrane by the PAC may present a challenge in UF/MF applications, demanding careful selection of the appropriate PAC grade, but that this was not an issue in MBRs. For in-situ dosing of MBRs with PAC, as pointed out by Steve, the PAC particles become bound within flocs and consequently do not abrade the membrane.

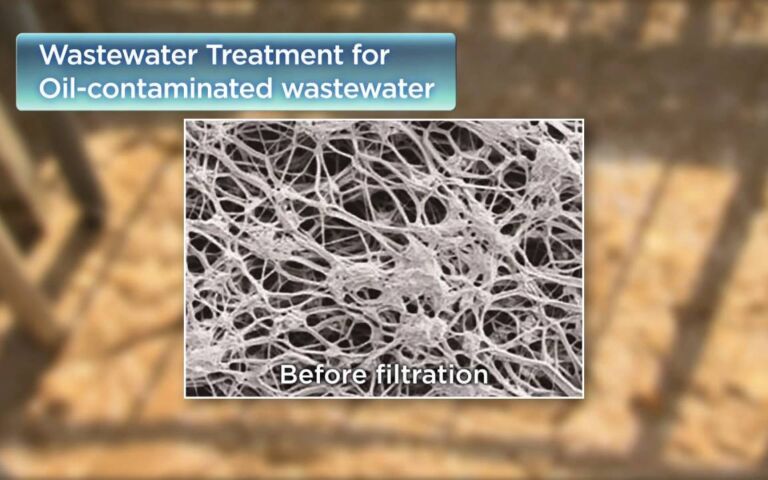

Amanda Bauchop (Passive Ltd) remarked that within the oil and gas (O&G) sector specialist proprietary adsorbent materials have been developed for oil removal from water, where the oil fraction presumably contains the bulk of the micropollutants. It is not known whether these adsorbents have been tested for micropollutants specifically, however. As with ion exchange beads these adsorbents are regenerable without using heat, but there is a loss of capacity with successive regeneration cycles requiring the spent material to be dumped. Graeme observed that selective adsorbents for PFAS have been researched but are not considered economically viable. However, as with all other commodities (an example being the flat sheet immersed MBR membranes in the early noughties), cost of supply is to an extent determined by demand.

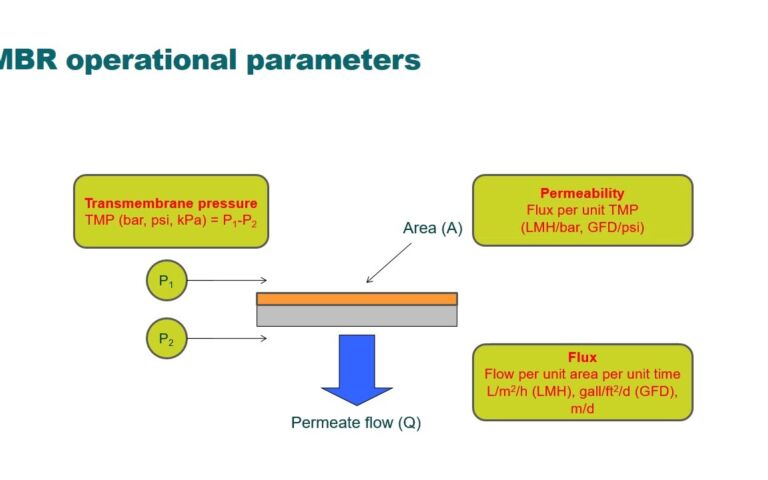

An interesting contribution was made by Sebastian Andreassen of Cembrane regarding ceramic membrane prices. Sebastian observed that ceramic membrane costs are generally steeply declining, partly down to the increasing number of players in the market in response to the increased demand. Fabrication costs have decreased by around one third due to automation of production. Nevertheless, the largest cost reduction, in terms of cost per m3 of treated water, associated with the technology relates to the process performance. Current flux rates for potable water applications of ceramic membranes are in the 600−800 LMH range in some cases – around an order of magnitude higher than those for a conventional polymeric membrane.

Graeme highlighted a large US project based on LG RO membranes where PFAS compounds have, as expected, been shown to be effectively removed. However, the management of the concentrate, and specifically its disposal, then becomes an issue. The disposal challenge is increased in the case of saline feedwaters in arid climates.

According to Simon, resource recovery from RO brines in general has conventionally focused on recovery of the NaCl specifically, and then converting the salt to chlorine and caustic soda by the chlor−alkali process. The prices of these reagents is highly unstable, making it hard to make a case based on economic viability. However, in purifying the salt, there will be waste streams which will presumably contain the PFAS and other micropollutants in concentrated form which, as indicated by Graeme, may then make some of the high-end oxidative processes more viable.

Pathogens

Simon pointed out that viruses are largely associated with (hydrophobic) solids: generally 98−99.5% are bound with the solids in the sludge. If a large concentration of solids with a large surface area is presented to the viruses in the mixed liquor then there is more chance of the viruses, along with any other hydrophobic pollutants, being removed through adsorption onto the surface of the solids. Conventional adsorbents (e.g. PAC) are particularly selective, but are considerably less expensive than the selective ones.

Steve Katz provided an update on the crediting of MBRs for pathogen removal by the USEPA. MBRs form part of multi-stage treatment schemes where individual unit operations are assigned log removal values (or 'credits') by the regulator. A recent guidance document has emerged in this regard: the Waterval work from Australia provided supporting evidence for assigning baseline credits from testing. This work was used as the basis for the US study to propose conservative Tier 1 LRVs of 1.0 for viruses and 2.5 for protozoa, and to develop validation protocols for assigning higher LRVs. This has provided clarification for implementing MBRs in advanced reuse processes.

The subject of MBR bacterial rejection performance for marine applications was taken up by Wei Chen (Wartsila). The International Marine Organisation (IMO) stipulate discharges from ships must satisfy a performance standard of 100 count/100 mL. This is more challenging than the US municipal wastewater discharge standards. In the Alaska region the standard is even more stringent at 14 count/100 mL. On cruise ships, the standard is met using MF with downstream UV, or UF alone (configured, for example, as multitubes). However, the rest of the ship industry has been slow in implementing appropriate technologies to meet these standards. The IMO currently provides no regulatory framework for wastewater recycling. Some cruise lines have tried to implement greywater recycling for general technical (non-potable) use, but progress in this area is hampered by the lack of a legal framework.

The subject of reuse on land in the UK was then taken up by Anna Nel (Severn Trent Water) in discussing green recovery, of which indirect potable reuse (IPR) forms a part. In IPR the wastewater is treated, discharged into stream or reservoir, then abstracted for potable use. This, rather than direct reuse without intermediate environmental discharge, arises from UK Drinking Water Inspectorate (DWI) stipulations. It then means that the wastewater contaminants, including the micropollutants and pathogens, impact on the environment. The pollutant load can be considerable: in some cases the effluent makes up 40% of the river flow. This suggests that advanced treatment for micropollutant removal should be applied to the wastewater discharge, rather than just to the abstracted water for potable use, to remove the micropollutants. The treated water may then also be reused by industry. This relies on industrial users in the vicinity of the works to take the treated wastewater, which can be a significant constraint. A bigger issue, however, is the lack of regulation for micropollutants. UK water companies are having to plan for assumed water quality regulations for these contaminants which currently have not been promulgated.

Microplastics

Amanda observed that the O&G industry is subject to increasingly stringent legislation, and are also challenged by significant quantities of microplastics in intake water streams. This then means that the water cannot be used for the period when microplastic levels in the intake are high. These microplastics presumably contribute to the COD levels in the rejected water, since the microplastics are ultimately oxidizable. Given the very significant amounts of water used by the sector, there is the potential for employing UF membranes for removing the microplastics. Graeme estimated that 99.8% recovery of the water could be achieved by a two-stage UF process, producing a low-volume, highly-concentrated waste stream. This stream would nonetheless present a problem on a site as small as an oil platform. However, the O&G industry has progressed substantially in the past decade in addressing such challenges.

Perhaps fittingly, there were no further comments offered from the audience on microplastics. Clearly, the monitoring, assessment and removal of this pollutant is a work in progress.

Finally, it would be wrong to end this piece without acknowledging Ropru Rangsivek of Watercare Service Limited: still online at the end of the meeting ... at 2am local time, Auckland. That's some stamina.