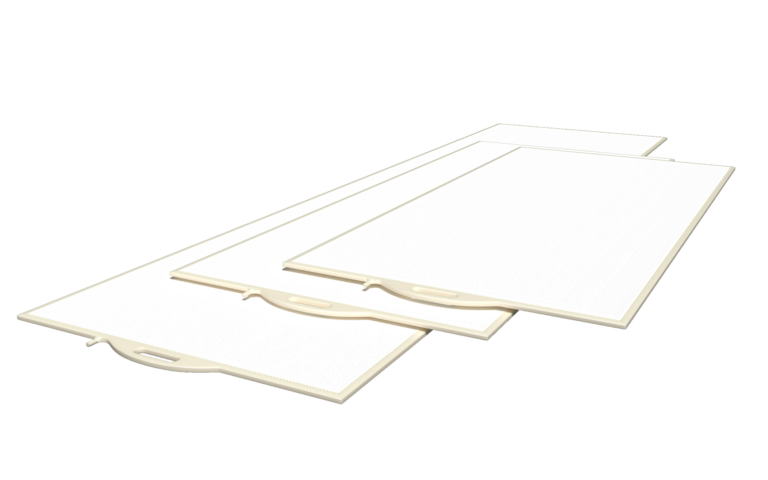

Immersed flat sheet MBR membranes: a summary of commercial products

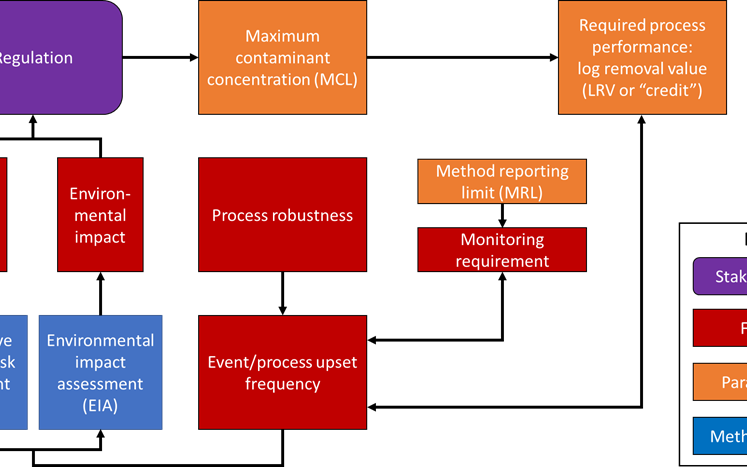

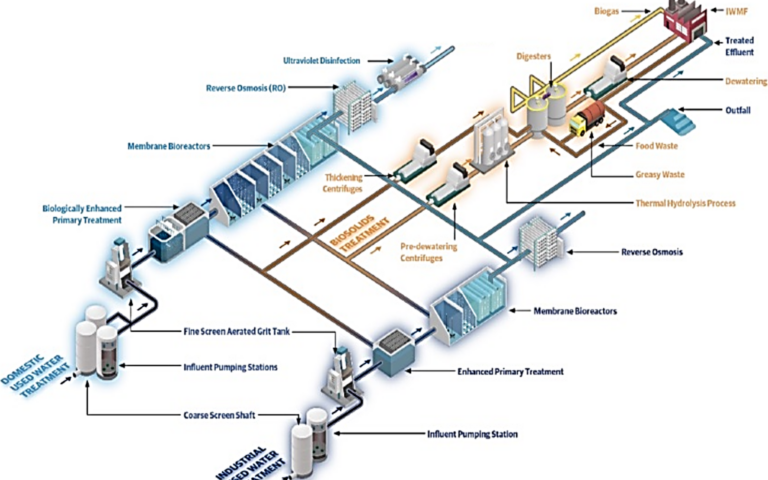

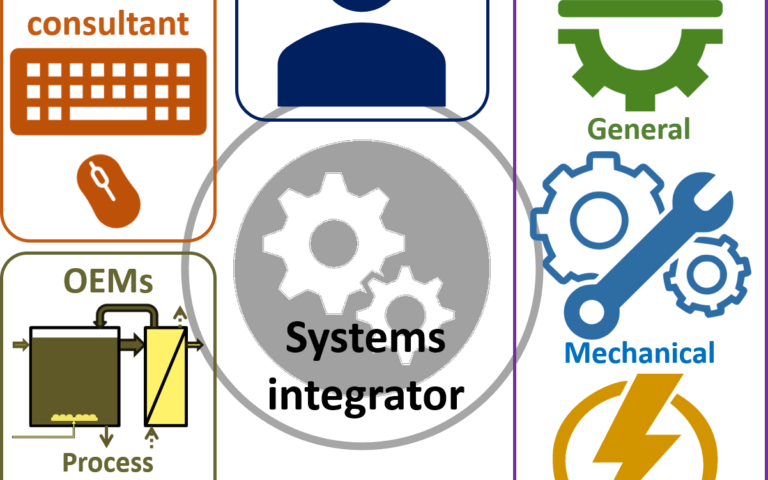

What commercially-available immersed flat sheet MBR membrane products are on the market for wastewater treatment? What are their structures, membrane material & pore sizes, and air scour rates, panel & module sizes including packing density and footprint?

Read article