The 2016 MBR Survey results

Last year, we asked 'What’s the main issue with MBRs?' This time our question focused on the topic of sludge − most of your responses from the previous three surveys had been based around this topic so we felt it was worthy of further investigation.

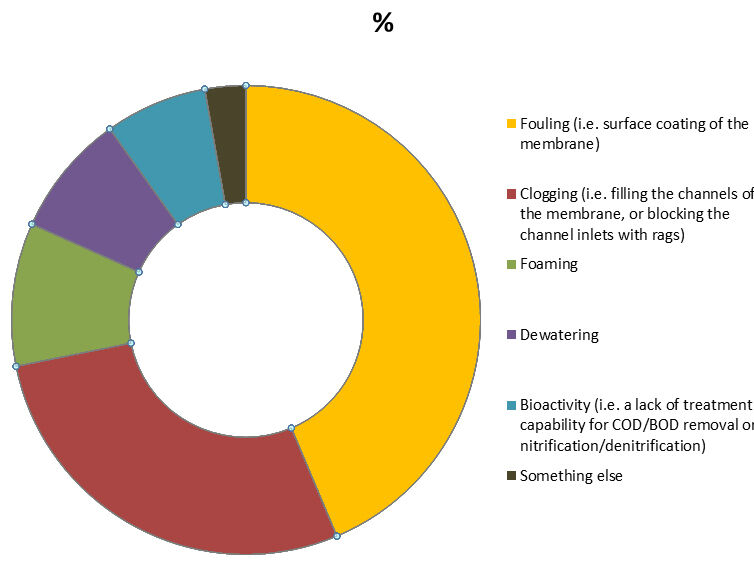

We received 50 responses to the 2016 survey. As might be predicted, the top two issues with MBR sludge quality were identified as fouling and clogging (Fig. 1).

However, unlike in previous surveys, fouling was well ahead of clogging as the primary challenge perceived by most of the correspondents. As has been discussed many times, irreversible membrane surface fouling and membrane channel clogging lead to the same symptoms of stubbornly low permeabilities with a largely ineffective chemical clean. It’s only by removing the membrane that it’s possible to distinguish between the two, with the clogged solids visible between the flat sheets or hollow fibres of the immersed membrane modules (When Sludge Goes Bad, May 2010). Clogging is a lot less of an issue − if one at all − for sidestream modules in pumped systems.

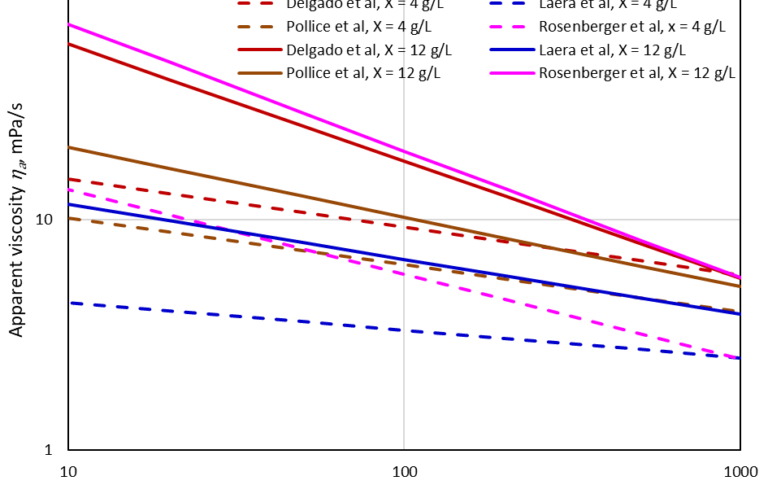

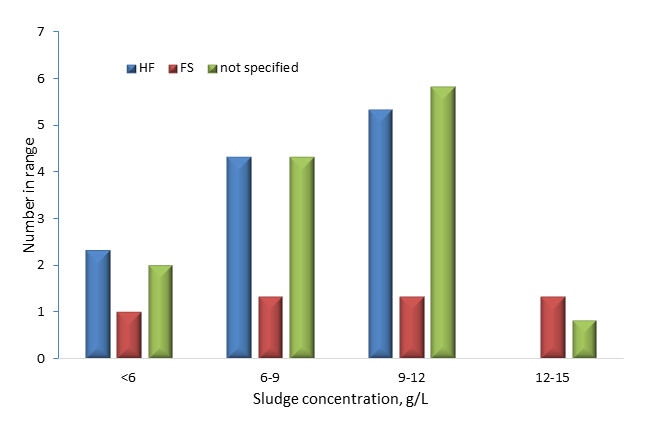

As far as the target value of the sludge concentration in the membrane tank is concerned, there were few surprises (Fig. 2). Some target concentration ranges were quite broad, and in such cases a weighting was applied (leading to half and one-third marks). The majority of the responses referred to hollow fibre MBRs, with only one dedicated to sidestreams (which was added to 'unspecified').

Overall, though, for the two data sets with enough data to form a recognisable trend ('HF' and 'unspecified'), there is around about a 55:45 split between the two regions of 9−12 g/L and 6−9 g/L in both cases, with a mean concentration of between 8.2 and 8.8 g/L. Again, this is not unexpected for HF membranes, though FS and MT membranes might be expected to tolerate slightly higher levels.

There was, naturally, a much smaller sample responding to our third question specifically about remedial measures taken when clogging is apparent. However, this is perhaps the most interesting aspect of the survey, since it indicates whether respondents have actually experienced clogging. In one case, a respondent has mentioned deflocculation of the solids, which is certainly problematic because of the associated release of colloidal material, but this actually promotes fouling rather than clogging.

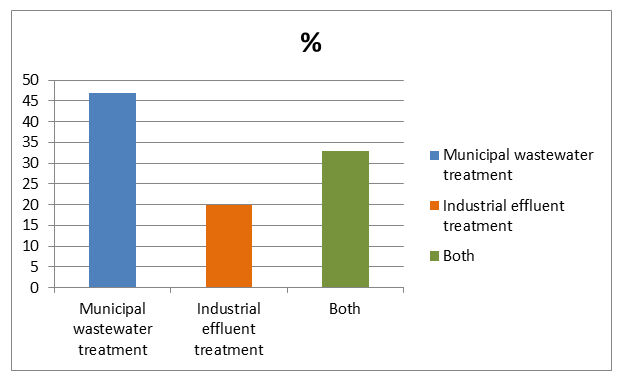

However, it is apparent that about 35% of the respondents to this question have had distinct clogging issues, and another 35% had not. As for remedial steps, it appears that for the most part manual cleaning of the membrane channels is still necessary, though it appears as though the flat sheet technology providers have developed methods for declogging the modules without necessitating removal of individual panels or sheets. It’s worth noting the distribution of applications of interest (Fig. 3): around 20% of the respondents were specific to industrial effluent treatment. This is a shade more than for previous surveys and may perhaps reflect the expanding industrial effluent treatment market.