Immersed vs sidestream MBRs − flux and shear

Flux and shear in MBRs

All membrane processes require a means of controlling membrane surface fouling and channel clogging. This is achieved through a combination of shear and membrane cleaning.

Shear is the force created when an air or liquid stream flows parallel to the membrane surface, which helps to limit the degree of fouling. Cleaning is either through physical or chemical means.

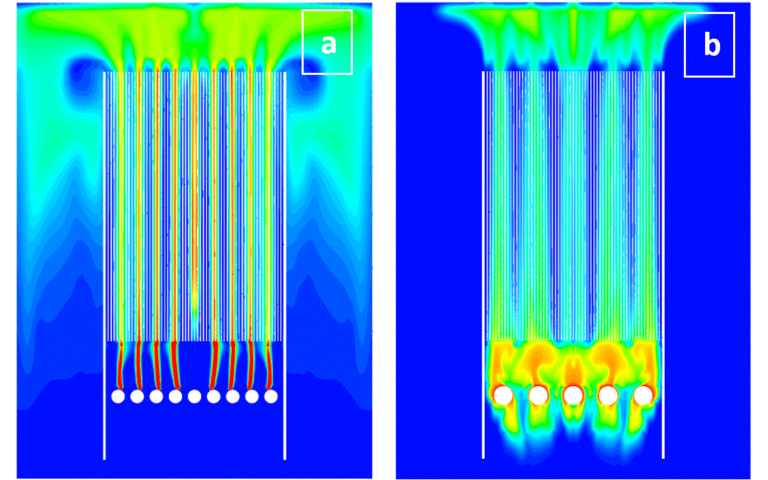

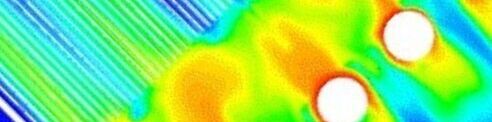

When MBRs were originally commercialised in the later 1960s/early 1970s, they were the pumped sidestream type where shear is created along the membrane surface by the sludge being pumped at a crossflow velocity of 2−4 m/s. In the case of immersed systems, the shear is created by the action of the air bubbles.

The flux (the permeate flow per unit area) through the membrane would be expected to increase with increasing shear. However, the rheology (the way in which a fluid flows) of MBR sludge is extremely complex, particularly for immersed systems, for the following reasons:

- the viscosity of the sludge changes with the shear applied, unlike water which has a constant viscosity

- the flow for immersed systems is intermediate in nature: it is neither fully turbulent nor fully laminar, and

- the aerated sludge in immersed systems has three phases: the air bubbles, the liquid and the floc solids.

These three things combine to make immersed systems extremely difficult to define rheologically, so making mathematical modelling very challenging, and meaning that it is hard to predict the behaviour of the sludge and the likelihood of fouling and, in particular, clogging.

Shear is arguably the most critically important aspect of MBR system design. For all membrane separation systems the ultimate aim is to generate sufficient shear to provide a sustainable flux with as little energy as possible. In general, the energy demanded to do this − in terms of energy (in kilojoules or, more usually, KWh) per unit permeate volume − decreases with decreasing flux.

Lower fluxes therefore normally offer an energy benefit. However, there is an associated cost penalty, since a lower design flux implies an increased membrane area requirement.

Design net fluxes (see Key MBR operation and maintenance parameters − membrane side) for municipal iMBRs are normally in the region 20−25 LMH, depending on the precise MBR membrane technology, the nature of the feed and the overall plant design.