Our research into membrane bioreactors in aquaculture

Astrid Buran Holan and Per-Arvid Wold

The authors are conducting research into MBRs in aquaculture at the Centre of Fisheries and Aquaculture at NTNU − Trondheim, the Norwegian University of Science and Technology

1. Introduction

As a result of an increasing demand for food worldwide, wild catches do not meet current demand − and aquaculture is the fastest growing agriculture worldwide, supplying a substantial amount of seafood consumed today. The ‘recirculating aquaculture system’ (RAS) is an upcoming production system in intensive fish production, which has many advantages as opposed to flow-through or cage systems. RAS is an on-shore closed system where over 90% of the water is recycled for production of live feed, larvae and fry and on-growing fish.

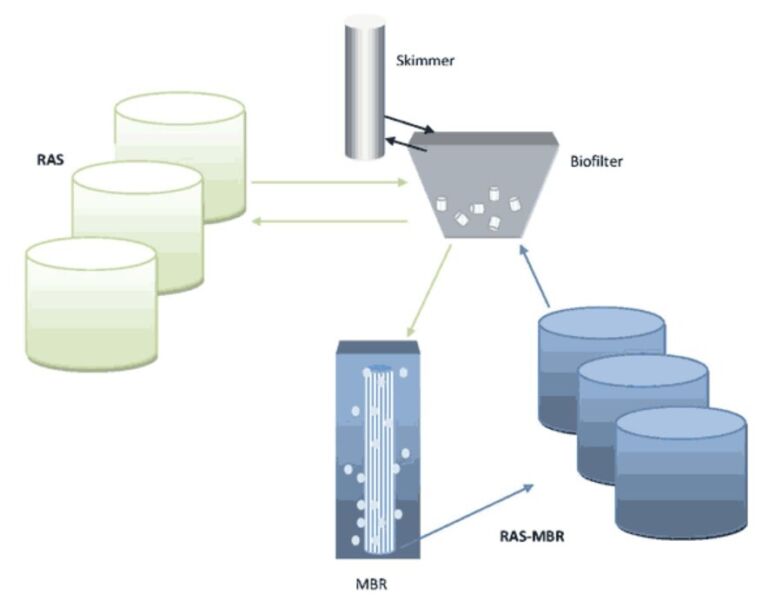

A conventional system comprises production tanks, a skimmer and/or some other device for particle removal, an aeration unit, a biofilter for removal of ammonia, nitrite and dissolved organic material and a disinfection unit like ozone or UV.

2. Benefits of recirculating aquaculture systems

By use of RAS, heat and water can be conserved, which makes it possible to establish aquaculture production in areas where the temperature is low or the water supply is scarce. RAS also eliminates the escape of farmed fish to the natural habitat.

Another increasing problem in the aquaculture industry using cage systems is the loads of biosolids and sludge deposits to the surrounding water area and the sea bed from uneaten food and faeces. Constant surveillance of feeding and water quality in RAS reduces this problem to a minimum.

Finally, RAS is suggested to control the bacterial population by microbial maturation of the water. A stable concentration of substrate as in RAS is a selective force to trigger water maturation and growth of a slow-growing beneficial bacterial community. In flow-through systems, there will be a variable content of microbe substrate, which is a force to trigger blooms of opportunistic and possible pathological bacterial species.

In water treatment systems in RAS of today, solids are filtered and rapidly removed by components for particle removal, usually a skimmer, a microscreen filter or a particle trap, to avoid mineralisation to smaller particles and sudden increase in nutrient in the water.

However, this water treatment leaves the dissolved, colloidal and fine fraction. This fraction will accumulate in RAS and potentially harm the system. Particles tend to dissolve into microbe substrate, lead to increased amount of nitrogen by mineralisation, offer protection from disinfection, smother the gill of the fish, harbor pathogens, clog the biofilters and increase the biological oxygen demand (BOD).

3. Membrane filtration in RAS

Introduction of membrane filtration is a potential technology in the further development of water treatment in RAS. There exist a number of commercial configurations of membranes integrated in municipal and industrial wastewater treatment systems, but not yet in aquaculture. Membranes might have several positive effects for the production in RAS by controlling the build-up of the colloidal and fine fraction of the solids and by that reducing the amount of organic material and particles in the water.

Common live feeds used in marine fish fry production today are the metazoa organisms rotifers (Brachionus ibericus) and the brine shrimp (Artemia sp.), and there have also been some attempts, at least in research, to feed the fish larvae with cultivated copepods for a short period.

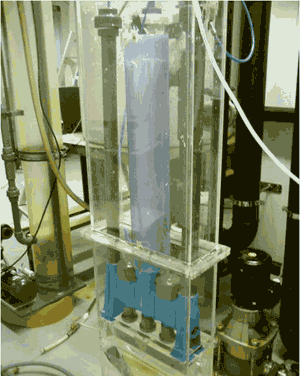

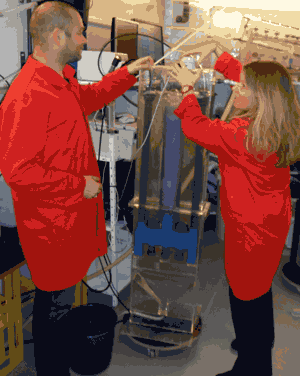

The aim of our project is to investigate the possible beneficial effects of including the MBR into our RAS system, with focus on particle removal and microbial stability. We designed and built a small scale RAS pilot plant (Figure 1) with a membrane bioreactor from Koch Membrane Systems (hollow fibre ultrafiltration membrane unit with 50 nm pore size) (Figure 2) for the production of copepods and rotifers.

The MBR was designed as an inside-out system where water entered the membrane core by applying a vacuum inside the membrane tubes. The system was run for 14 days (copepods) and 17 days (rotifers) and compared with commercial RAS.

4. Preliminary results

Preliminary results suggest that membrane filtration visually affects water quality in the production tanks, and that hydraulic retention time and the amount of water filtrated through the membrane has a great impact on how the membrane actually affects the water quality in the system. The membrane was operated as a dead-end filtration module and seemingly, this resulted in an increased level of dissolved organic carbon in the system.

However, further research is needed to establish the optimal application for MBR in RAS, especially regarding membrane operation, dead-end or cross-flow, hydraulic retention time and system configuration.

We at NTNU are continuing our research efforts in this area, with the intention of publishing our results in due course.