Distillery effluent treatment with anerobic MBR technology: the Glenmorangie site

Simon Judd, Director at Judd Water & Wastewater Consultants, visits one of the earliest UK examples of anaerobic MBR (AnMBR) technology treating industrial effluent

1. Background

A few weeks back we found ourselves loitering outside the Visitors Entrance of the iconic Glenmorangie distillery (Fig. 1) near Tain on the beautiful North East coast of Scotland (and, conveniently, just a few yards off the NC500 route). Unlike the other punters in the vicinity, we weren’t there to view the whisky-making process − and, presumably, enthusiastically sample the end product. We had instead arranged to see one of the earliest UK examples of anaerobic MBR (AnMBR) technology, in this instance designed to treat the 500-or-so m3 of industrial effluent generated daily from the process.

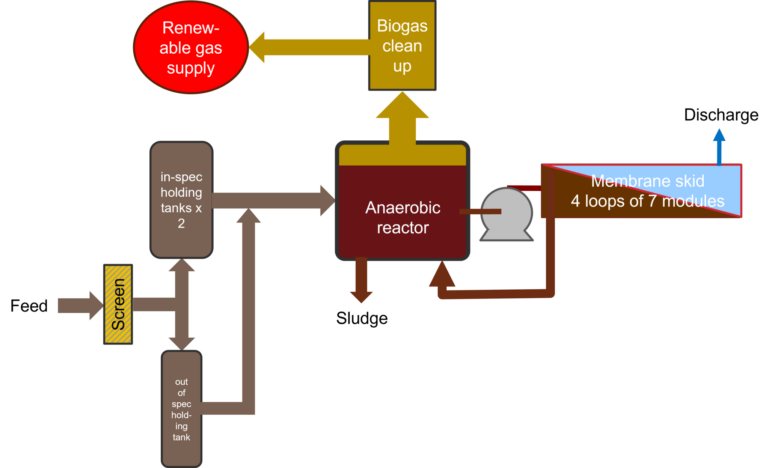

The AnMBR effluent treatment plant at the distillery site was commissioned in 2016. The process essentially comprises a conventional outdoor anaerobic digester (AD) integrated with sidestream multitube (MT) membranes (Fig. 2), the membrane skid being housed in a dedicated building. The process was designed by Aquabio/Freudenburg and has been operated by Alpheus since 2020.

2. Treatment process

The effluent enters the works to a single 0.7 mm-rated rotary screen (Fig. 3) before being fed to a small monitoring tank of around 6 m3 capacity (Fig. 4) and which contains probes for measuring the water quality (pH, oxidation-reduction potential and temperature). In-spec water is fed to two tanks of ~150 m3 capacity each (Fig. 5), offering a total equalisation time of around 14 hours at the mean inlet flow of 500 m3/d. Out-of-spec effluent is directed to a third tank of the same shape and size (but a different colour). This out-of-spec effluent is blended back into the flow from the in-spec tanks over an extended period to provide overall in-spec feedwater to the downstream anaerobic process.

The feedwater is heated (or, if necessary, cooled) to 35−40°C prior to being fed to the 2100 m3 anaerobic reactor (Fig. 6). Heating for both the reactor and the feedstock is provided by waste heat from the distillery. The reactor mixed liquor is jet-mixed using two pumps each providing recirculation at 200 m3/hr (400 m3/hr total), equating to a reactor residence time of approximately five hours.

The AD generates around 200 Nm3/h of biogas from the effluent flow of up to 10 m3/h and a design COD load of 14500 kg/d. The biogas, which normally contains up to 60% methane and ~40% carbon dioxide along with significant low levels of hydrogen sulphide, was originally chemically scrubbed using a caustic soda solution. This process has been recently replaced by a new biological scrubber (Fig. 7) that uses a biological process to provide effective removal of hydrogen sulphide to improve sustainability and minimise chemical use. The process is effective in reducing hydrogen sulphide down to trace levels through biochemical oxidation to sulphuric acid. There is also a supplementary odour control column, required to reduce odours in the vicinity due to the proximity of the distillery visitor centre.

The cleaned biogas is stored in a 650 Nm3-capacity spherical gas bag (Fig. 8), from where it is directed back to the distillery where its latent thermal energy is harnessed.

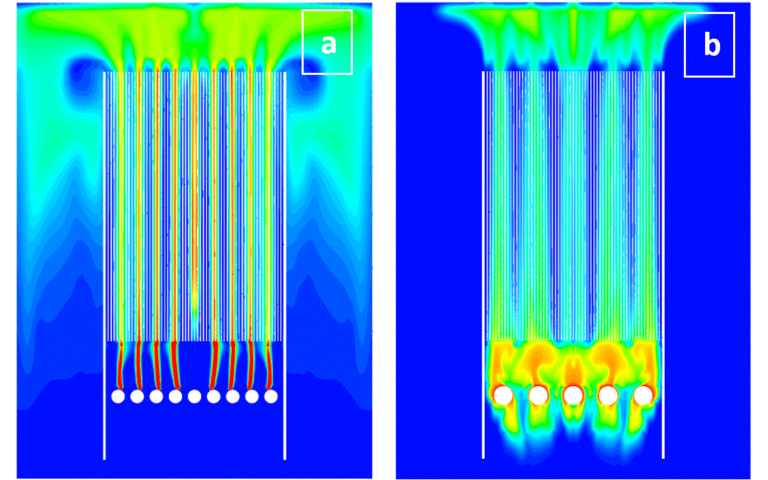

The digestate from the AD is fed to a membrane skid comprising four lines (or loops) of seven MT membrane modules, 28 in total, in the classic serpentine configuration generally used for pumped systems (Fig. 9). The modules, supplied by Berghof, are 4 m-long and the standard 200 mm external diameter. Each module contains 523 membrane tubes of 8 mm internal diameter, and are rated at 45°C maximum temperature. The modules are subject to a stringent maintenance cleaning schedule in order to extend their life as long as possible.

The membranes are operated in low-energy (‘LE’) mode, at a relatively modest crossflow velocity of 0.5 m/s and a commensurately low transmembrane pressure (TMP) of up to 2 bar. The crossflow is provided by four recirculation pumps (Fig. 10), one per loop, each rated at 250 m3/h at 42 m head.

Operation under these filtration conditions of crossflow velocity and TMP generates an average flux of 11 LMH, and a corresponding mean permeability of 6 LMH/bar, for filtration through the MT membranes. This compares with much higher fluxes of 50−80 LMH for the corresponding aerobic process (Judd, 2014), illustrating the widely recognised greater challenge posed by anaerobic mixed liquors compared with aerobic ones.

The sidestream process configuration permits flexibility of membrane operation, with the number of loops online at any time being adjusted in accordance with the influent flow. The influent flow is in turn determined by the mixed liquor height in the AD tank. Membrane loops switched to offline at low influent flows are rinsed with water ready for re-introduction when required at higher flows. The ability to rapidly bring the membrane loops on and off line represents a key attribute of sidestream MBR processes.

The modules are backflushed every 30−40 minutes and maintenance-cleaned daily. Details of the complete chemical cleaning protocol are considered proprietary by the operators.

Permeate from the membrane separation step is stored in a 400 m3 tidal tank (Fig. 11) for discharge to the Dornoch Firth at sea level height, allowing discharge when the tide is coming in or going out as well as at high tide.

The struvite precipitation potential of the effluent is high enough to demand acid dosing of the permeate to avoid scaling problems in the pipework and the downstream tidal tank.

3. Performance

The plant has met the overall performance requirements, removing 98% of the influent BOD (Fig. 12) while meeting 20% of the energy demand of the whisky-making process from the recovered biogas. The nutrient-rich solid waste stream discharged from the AD is employed for local agriculture as a fertiliser for grassland fields.

A few unexpected challenges over the course of the five years of operation by Alpheus have included:

- an extended hibernation period brought about by the pandemic, and

- the mechanical upset of four of the membrane modules which appears to be due to some sort of pressure shock.

The pandemic led to the shutdown of the plant for 2 months – a carefully planned process that was devised and implemented to address this unexpected challenge. The team managed to get the plant up and running again within 21 days, demonstrating the robustness of the process in this regard.

Although a pressure shock of some unknown origin is suspected, apparently affecting just four of the 28 membrane modules, the precise root cause has not been identified so it's not possible to know this with any certainty. The remaining membranes have otherwise retained their permeability thanks to the O&M protocols adopted, with no other membrane replacement required since the commissioning of the plant. The normal membrane life at this site thus appears to exceed eight years.

4. Participation in landmark research programme

The site has been the focus of a previous pilot-scale research project (part of a larger European Horizon 2020 programme on resource recovery from industrial effluents) devoted to the recovery of high-quality water and nutrients from the treated wastewater.

The recovered water can potentially be demineralised using reverse osmosis, and subsequently used for internal cleaning processes within the distillery, conserving freshwater supplies.

The recoverable nutrients comprise phosphorus and ammonia. The phosphorus, along with some of the ammonia, is precipitated as struvite which can then be used as a fertiliser. The remaining ammonia, also a potential fertiliser, can be extracted as a gas by air stripping, which makes use of waste heat in the bioreactor effluent. This approach could potentially recover 122 and 47 tonnes per year of struvite and ammonia respectively from the distillery effluent.

5. Acknowledgements

Our grateful thanks to Glenmorangie, to Alpheus − who operate and maintain the Glenmorangie site − and in particular to Colin Wilson of Alpheus for taking time out to show us around the plant. Colin has played a key role in operating the plant since 2018. As a proud owner of a 1200cc Triumph Scrambler, he obviously appreciates good engineering.