Which MBR?

Simon Judd has over 35 years’ post-doctorate experience in all aspects of water and wastewater treatment technology, both in academic and industrial R&D. He has (co-)authored six book titles and over 200 peer-reviewed publications in water and wastewater treatment.

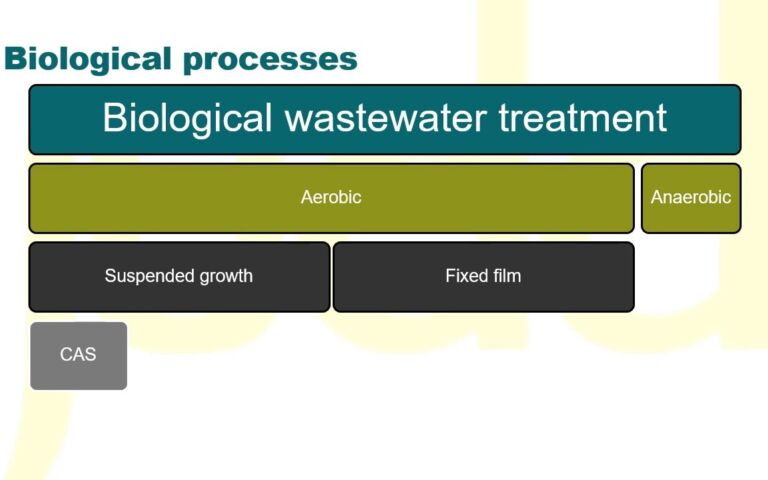

The choice of MBR technologies is, it would appear, a series of dichotomies or dilemmas: anaerobic vs aerobic, immersed vs sidestream, ceramic vs polymeric, flat sheet vs hollow fibre (for immersed), pumped vs air-lift (for sidestream). You could just flip a coin. However, if one is going to resort to more rational methods, then it is perhaps worth considering what's already out there in the marketplace.

The most prominent configuration in terms of volume of treated water is the immersed hollow fibre (iHF), which seems to be the technology of choice for large flows (>50 MLD). Currently, all of the 20 largest MBRs are iHF based, though this will change when the plant at Canton in Ohio is completed next year.

In terms of the numbers of installations, the immersed flat sheet (iFS) tops the list. Both these immersed configurations are favoured over the more established pumped sidestream technology (sMBR), normally based on multi-tube (MT) membranes, on the basis of lower energy demand. However, the lower footprint of the membrane separation component of the pumped MT sMBRs, along with their operational flexibility and perceived robustness, means that they are often favoured for industrial effluent applications.

So, what about anaerobic systems, ceramic membranes and air-lift sidestream? All of these are minor players currently. There are probably fewer than 30 MBRs in total based on ceramic membranes. This may well change if the cost of ceramic membranes continues to fall, but polymeric materials (and PVDF in particular) currently overwhelmingly dominate.

Anaerobic MBRs have been around for at least 20 years in some guise or other but their viability tends to be limited to very high loads and cases where nutrient removal is either not a requirement or else can be addressed by a downstream aerobic process. There are thus perhaps fewer than 20 anaerobic MBRs installed globally.

Air-lift (or air-scoured) sidestream technologies, on the other hand, would appear to be more generally applicable since they operate at a similar energy demand as the immersed configurations and so are viable for municipal wastewater treatment, which remains the dominant market sector for MBRs. It is unclear how many A-L sMBR installations there are in the world but they are offered by a number of different technology suppliers and there may be as many as 100 or more.

So, the choice, as ever, comes down largely to cost. And there are, of course, different ways of costing. Low annual operational costs will result in reduced whole-life costs (since over the life of a plant it is the operational costs which generally make up the greater proportion of the total outlay) and for small plants 'low operational costs' generally equates to low manual intervention.

For a large municipal MBR the choice is likely to be an iHF. For a small, biorefractory industrial effluent stream on a site where there is just about enough space to swing a cat and little staffing then a ceramic sMBR may be considered viable. If capital cost is the be-all and end-all, then it's down to the price tag on the individual technologies and the respective positions taken by the client, consultant and supplier. And that's why we have creative accountancy, though it didn't work out so well in October 2008.