Reuse of dairy wastewater treated by membrane bioreactor and nanofiltration: technical and economic feasibility

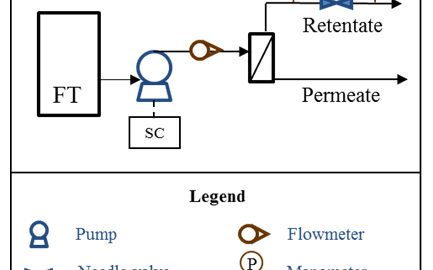

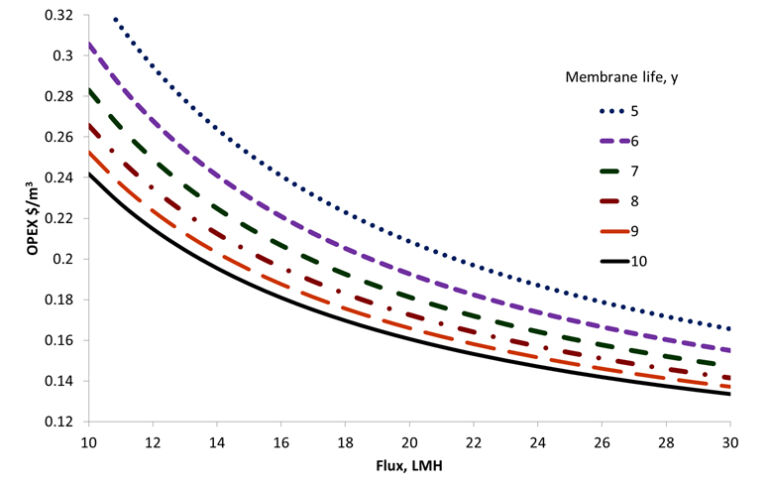

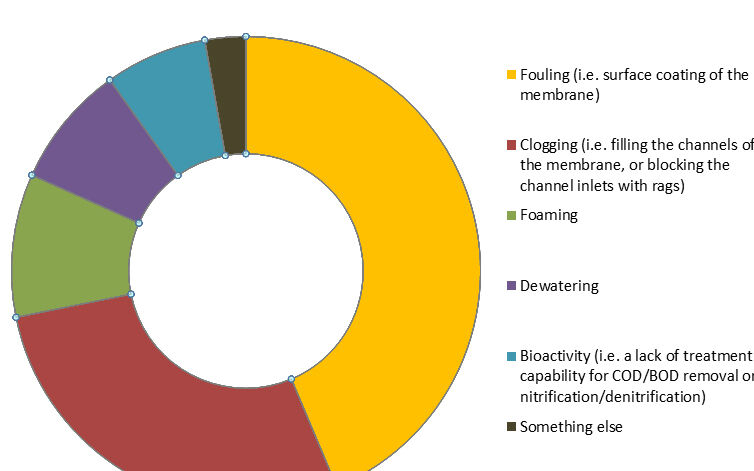

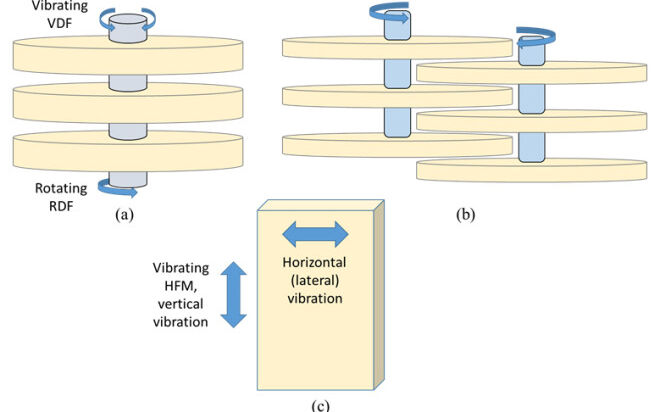

A study carried out by Andrade et al assessed the viability of a two-stage membrane bioreactor−nanofiltration scheme (MBR−NF) for treating dairy wastewater. They assessed quality of the treated water with respect to its potential reuse and overall cost.

Read article