Lagunitas Brewing Company wastewater treatment plantview Toray

Application:

Food, beverage and dairy

Toray MBR

About Lagunitas Brewing Company wastewater treatment plant

WATER FOOTPRINT OF BEER

Beer production is a water-intensive process having an average water-to-beer ratio of 4 to 1. About 25 percent of the water goes into the final product, while non-product contact processes such as cleaning, cooling, and packaging consume the remaining majority volume. Breweries without a reclaim water system will send this vast amount of water to the drain or lose it to evaporation[1].

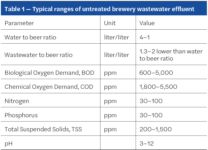

Wastewater generated by beer production is high in organics containing large amounts of protein, fat, fiber, carbohydrates, yeast, hops residue, ethanol, and suspended solids. Table 1 shows the typical parameters of untreated brewery wastewater, as defined by the Brewers Association, characterizing brewery wastewater as 'high-strength'.

The high organic content wastewater may overwhelm operations at municipal treatment plants, whereby the municipalities cannot receive the effluent or receive it at a high surcharge. Such instances will force breweries to haul wastewater to larger treatment facilities, or at worst case, scale back operations.

ON-SITE WASTEWATER TREATMENT

Lagunitas Brewing Company in Petaluma, California, is one brewery that has successfully mitigated these challenges. Before implementing an on-site wastewater treatment plant, Lagunitas transported 50,000 gallons per day of its high-strength wastewater to a wastewater treatment facility located 50 miles away, while also sending its low-strength effluent to a nearby municipality. Fees for wastewater disposal and treatment were estimated to be around $180,000 per month, making up 87 percent of water costs.

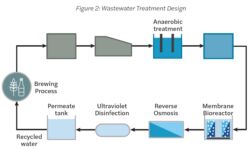

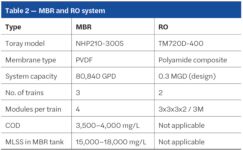

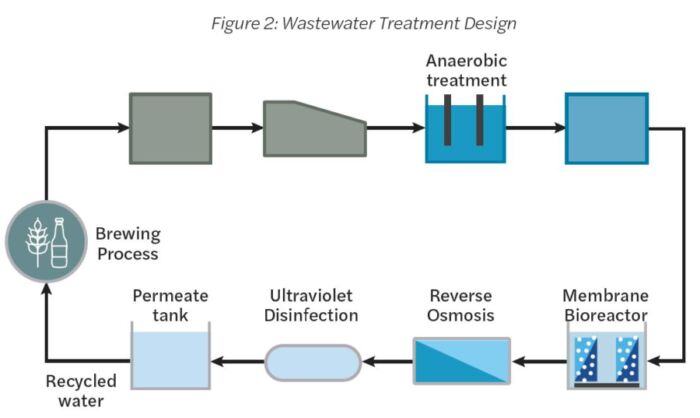

Lagunitas integrated reuse into the wastewater treatment design using Toray's membrane bioreactor (MBR) and reverse osmosis (RO) membrane technologies. Toray's flat-sheet MBR module removes 99% of contaminants sending the filtrate to RO for polishing to exceptionally high standards and creating more reuse opportunities of the reclaimed water within the brewery process. The durable and low-fouling characteristics of Toray's MBR and RO membranes operate reliably under wastewater conditions for longer membrane life, cleaning range, and reduction of overall costs. As a final step, ultraviolet disinfects the RO permeate to eliminate any remaining bacteria.

The on-site treatment scheme recycles approximately 70 percent of the wastewater back into the brewing process.

RESULTS

Lagunitas achieved the following with the use of an advanced membrane treatment system[2]:

- Reduction of water-to-beer ratio from 4:1 to 2.5:1

- Approximately 40% reduction in water usage

- About 70% reduction in wastewater volume.

Lagunitas experienced continued growth in its business and needed to expand its wastewater treatment capacity. In February 2019, the existing TMR140-100S modules were retrofitted with NHP210-300S, Toray's latest MBR technology. Utilizing thinner membrane sheets based on the same durable PVDF membrane technology, the NHP features a 50% higher packing density per module, improved cleaning and fouling resistance, and is 66% lighter to simplify logistics and installation. The existing module diffusers were cleaned and reused with the NHP modules, further saving capital equipment costs.

As breweries seek to reduce their water footprint, reuse strategies employing efficient membrane technologies are proven to be a sustainable choice for water management and quenching the thirst of beer enthusiasts worldwide.

REFERENCES

[1]Brewers Association. "Water and Wastewater: Treatment/ Volume Reduction Manual." October 2016.

[2]Rixey, Eppa. Silver, Matthew. "Water Reuse at Lagunitas Brewing Company." Water Reuse in Beverage Production — Beer & Bubbles. December 2015.

Company summary

About this page

This page was last updated on 22 April 2021

Disclaimer

Information on this page may have been supplied by third parties. You are reminded to contact any third parties to confirm information is accurate, up to date and complete before acting upon it. TheMBRSite.com accepts no liability for information provided by third parties, actions taken on the basis of this information or information held on third-party websites.