Defining MABRs, MBBRs and MBRs − terms and terminology

Simon Judd has over 35 years’ post-doctorate experience in all aspects of water and wastewater treatment technology, both in academic and industrial R&D. He has (co-)authored six book titles and over 200 peer-reviewed publications in water and wastewater treatment.

Years ago, I was in discussion with a very eminent anaerobic treatment researcher who had just leapt onto the MBR research bandwagon. He had decided to abbreviate a submerged anaerobic MBR system to an 'SAMBR'. It was pointed out to him that an 'S' could stand for either 'submerged' or 'sidestream', and an 'A' to either 'aerobic', 'anaerobic' or 'anoxic'.

It was suggested to him that the existing term for such a technology 'AniMBR' (anaerobic immersed MBR) was less ambiguous. Naturally, he did what any other internationally-leading professor would do and ignored all advice and stuck to his own pet term.

Ambiguous abbreviations are one thing − but the confusion caused by abbreviations which look pretty similar but refer to completely different things is yet another matter. This is the case with the MABR, MBBR and MBR technologies. Let’s face it, the acronyms do kind of suggest that they are related. But they are actually quite different, as outlined in the table below.

| Abbreviation | Name | Process category | Purpose |

|---|---|---|---|

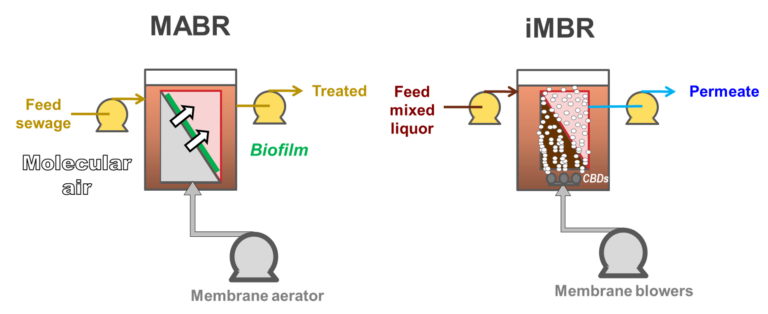

| MABR | Membrane aerated-biofilm reactor | Fixed film | Intensive (low-footprint) biological treatment using a membrane both as the biofilm substrate and for molecular ('bubbleless') aeration |

| MBBR | Moving bed bioreactor | Fixed film | Controllable biological treatment at relatively low energy demand using agitated media as the biofim substrate |

| MBR | Membrane bioreactor | Suspended growth | Intensive (low-footprint) biological treatment using a membrane for clarification and substantial disinfection |

Only two of the processes (the MABR and the MBBR) are fixed-film in configuration, whereas the MBR is a modified activated sludge (or suspended growth) process. Since only the MBR provides membrane separation of the water from the solids, it’s also the only one of the three providing substantial disinfection and pretty much complete clarification. Against this, the MBR is generally higher in energy consumption and more complex in operation because of the requirement to control permeation through the membrane.

So far, so slightly confusing. But, finally, there’s the proliferation of the MBR terms themselves which, like the abbreviations, seem to multiply with the passing of time. 10−15 years ago there was a US committee formed which attempted to formulate a consistent terminology to be used for MBR technology. I remember Dennis Livingston – an erudite, unduly modest and entirely personable man – alerting me to it and our subsequent discussions.

My understanding is that the committee eventually concluded that the task was insuperable, and threw in the towel. So, today the components of the membrane and MBR system are variously described as elements, modules, cartridges, curtains, candles, panels, sheets, tubes, cassettes, skids, units, stacks, loops, sub-modules, sub-units ...

... Sorry, am I boring you?

If you’d like to learn a bit more about the MABR technology, read our selected list of ten abstracts from recent research papers.