Ragging in MBRs − how do rags form?

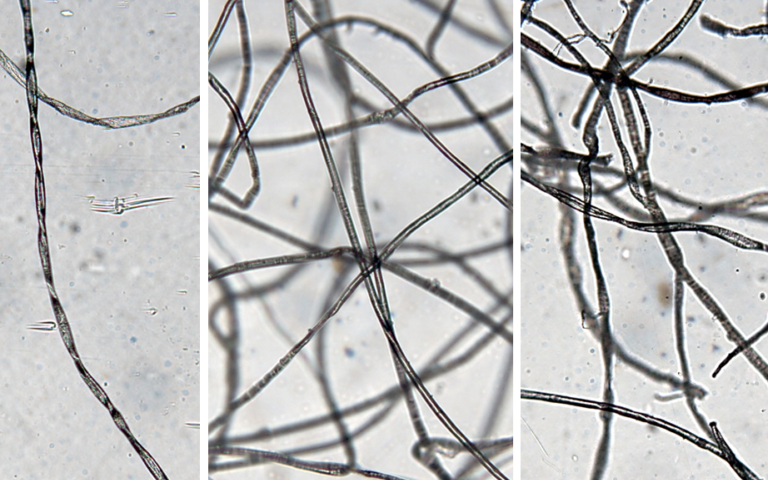

Ragging is a type of clogging, where clogging relates to agglomeration of solids in the membrane tank. In the case of ragging, filament solids from textile materials join together to form long braids which are mechanically stable in the mixed liquor.

Read article