Crestview Water Reclamation Facilityview Toray

Application:

Municipal

Toray MBR

About Crestview Water Reclamation Facility

BACKGROUND

In January 2010, Toray's flat-plate membrane bio-reactor (MBR) modules began operation at the Bob Sikes Water Reclamation Facility (WRF) in Crestview, Florida. The plant is designed to treat an annual average daily flow (AADF) capacity of 1.0 MGD (3,800 m3/d).

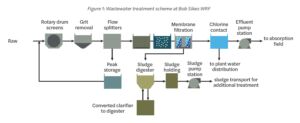

The overall wastewater treatment system consists of the following:

Headworks with screening; Grit removal; Peak flow bypass facilities (flow splitters); Three-train MBR treatment process with anoxic and aeration basins; Chlorine disinfection; Effluent pump station; Aerobic sludge digesters; and Holding tank and pump for sludge transportation for additional treatment. Lastly, the treated effluent is pumped to an absorption field system for reuse.

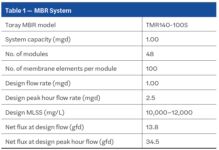

Each MBR train contains two MBR tanks housing eight TMR140-100S modules totalling sixteen modules per train. The total number of MBR modules installed is forty-eight in the three-train MBR filtration system. Details of the MBR system is outlined in Table 1.

The membrane used in Toray MBR modules is a composite structure of Toray's durable PVDF (Polyvinylidene Fluoride) membrane layer as the functional membrane material on a PET (polyester) non-woven support fabric. The robust and flexible composition of the membrane structure gives Toray MBR modules high physical strength and chemical stability.

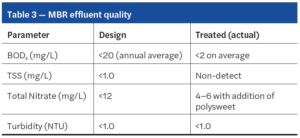

The Bob Sikes WRF facility is authorized to direct reclaimed water for reuse to an absorption field system, based on the treated water quality shown in Table 2.

The designed parameters for the MBR system, compared to actual treated water quality is shown in Table 3.

SUMMARY

The treated water quality far exceeds the permit requirements for reuse with TSS non-detect and BOD less than 2 mg/L on average.

The successful long-term operation was possible at the Bob Sikes WRF in treating 1 MGD of mixed liquor for over ten years due to the facility's competent staff and the high physical strength and chemical stability of Toray MBR membranes.

Company summary

About this page

This page was last updated on 22 April 2021

Disclaimer

Information on this page may have been supplied by third parties. You are reminded to contact any third parties to confirm information is accurate, up to date and complete before acting upon it. TheMBRSite.com accepts no liability for information provided by third parties, actions taken on the basis of this information or information held on third-party websites.