The MBR Site report: Singapore International Water Week, 2021

Singapore International Water Week has become a landmark event in the water and wastewater management conference calendar. This year, the programme ran from 21 June−2 July, a total of ten days of online sessions.

Simon Judd summarises the 27 MBR/MABR presentations

SIWW21 MBR and MABR presentations

The programme of the 2021 Singapore International Water Week included no fewer than 27 MBR presentations, comprising 15 platforms and 12 posters (Table 1). Not surprisingly there was a preponderance of presentations from Singapore. Although there was only one dedicated MBR session, many of the presentations were scattered across the other sessions.

| Title | Affiliation | Presenter or corresponding author |

|---|---|---|

KAUST King Abdullah University of Science and Technology | ||

| Platforms | ||

| The Application Of Computational Fluid Dynamics With Integrated Biokinetics To Accelerate Process Innovation In The Water Industry | AM-TEAM | Wim Audenaert |

| From Validation To Full-Scale Design: Dedicated Zoo Animal Wastewater Treatment And Reuse | Binnies | Sock Hoon Koh |

| Application Of Ultrafiltration Coupling Processes To Tackle Challenges In Industrial Wastewater Treatment | CITIC Envirotech | Jerry Liu |

| Integration Of MBR And Hybrid Constructed Wetland For Enhanced Treatment Of Rural Domestic Sewage | CITIC Envirotech | Jinsong Zhang |

| MBRs: Academic Research vs Practitioner Needs | JWWC | Simon Judd |

| Microbial Ecology Of Anaerobic Membrane Bioreactor (Anmbr) And Its Relevance In Mitigating Membrane Biofouling | KAUST | Peiying Hong |

| Performance Of Newly Developed Intermittent Aerator For Flat-sheet Ceramic Membrane In Industrial MBR System | Meiden | Hiroshi Noguchi |

| Membrane Bioreactor For Indirect And Direct Potable Reuse Applications To Treat Primary Or Non-nitrified Secondary Wastewater Effluent | MWDSC | S Liang |

| The Resource Efficient Integrated Membrane Bioreactor System | PUB | Guihe Tao |

| Demonstrative-scale SIAM Technology Trials In Dairy And Slaughterhouse Factories | Suez | Xavier Bernat |

| MABR – an Innovative Solution for Resilient Wastewater Treatment | Suez | Jeff Peeters |

| Ultralow Energy - No Bubble Deammonification | Suez | Gabriel Kicsi |

| Testing MABR technology at Ejby Mølle | VCS Denmark | Nerea Uri Carreño |

| Maximizing Asset Capacity And Performance Via Process Intensification Using MABR Technology | Water Corporation | Wayne Bagg |

| Simultaneously Anaerobic Digestion and Low-carbon Denitrogenation in Sewage Mainstream by Integrating Anaerobic Membrane Bioreactors With Nitritation-Anammox | Xi'an Univ | Zhen Lei |

| Posters | ||

| Process Intensification By Using Hybrid Integrated Fixed Film - Membrane Bio Reactor (IF-MBR) For Treatment And Reuse Of Refinery Wastewater | AECOM | Sai Kit Chee |

| Integrating MBR Systems To Potable Reuse Treatment Schemes And Associated Pathogen Removal Capabilities | Binnies | Ufuk Erdal |

| Taking MABRs Out Of The Box And Into Practice - BNR Intensification With Bubbleless Aeration | BV | Sandeep Sathyamoorthy |

| Membrane fouling at high MLSS | CITIC Envirotech | Zanguo Peng |

| Review of 100 Commercial MABR Installations in China | Fluence | Gilad Yogev |

| Advanced Nephelometry Coupled with Real Time Membrane Integrating Turbidity Monitoring | Hach | Vishnu Rajasekharan |

| Improvements In Ceramic MBR System For Industrial Used Water To Achieve Higher Operational Stability And Energy Efficiency | Meiden | Hiroshi Noguchi |

| Integrated Anaerobic Fixed-Film MBR-Reverse Osmosis-Chlorination Process: An Environmentally Sustainable Approach For Reclamation Of Municipal Used Water | Nanyang Univ. | Siyu Wang |

| Towards High Recovery In Water Reclamation Processes: High Performance NF-MBR+RO System | Nanyang Univ. | Tzyy Haur Chong |

| Design Features And Initiatives At Tuas Water Reclamation Plant | PUB | Zheng En Lim |

| New Method For Integrity Monitoring Of Membrane Bioreactors | Suez | Stephen Katz |

| Reduction Of Energy Consumption In MBR With New High Performance (NHP) Module | Toray | Kyaing Kyaing Latt |

The subjects covered were nothing if not eclectic – in keeping with the rest of the conference topics. Of these 27 presentations:

- five were devoted to the membrane-aerated biofilm reactor (MABR) technology

- seven related to water reuse generally and indirect potable reuse (IPR) specifically, including two focusing on membrane integrity monitoring

- four provided details of an industrial effluent treatment/reuse application, some of these based on some sort of hybrid process

- four were anaerobic processes, including one of the above industrial effluent demonstration projects, and

- a few concerned miscellaneous topics such as modelling, combination with a polishing process (reverse osmosis or constructed wetlands), and operation under challenging conditions (such as high MLSS).

Quite a few presentations were based on pilot, demonstration or full-scale applications, and it’s rather encouraging to be presented with outcomes of studies conducted under real-world conditions.

Although by no means exhaustive, this report covers some of the key elements of the above.

1. Membrane-aerated biofilm reactors

The MABR presentations predominantly concerned examples of full-scale implementation, including:

- selection of the MABR process over competing technologies for retrofitting at the Beenyup and Subiaco water resource recovery (WRR) plants in Western Australia (Bagg, Water Corporation)

- an account of the start-up of an MABR retrofit (as a sidestream) at the Ejby Mølle WRR facility in Denmark, under low-flow conditions (Carreño, VCS Denmark)

- demonstration of the recovery of the technology − to provide more than 80% of pre-shutdown performance within an hour following a 24h shutdown period − at the Adelaide wastewater site (Peeters, Suez)

- a summary of the outline performance of an MABR technology implemented in China (Yogen, Fluence).

The last of these is perhaps the clearest notice possible of the extent and rapidity of the implementation of the MABR technology. The poster offered performance data from 77 of the Fluence MABR plants operating in China, all apparently installed in the past four years. Data indicated the required levels of nitrification were achieved despite wide fluctuations in nutrient loading rates and operating temperatures.

There was one further paper, from Gabriel Kicsi of Suez, which provided some outline data on a pilot-scale demonstration of the Zeelung technology used for partial nitritation−anammox (PN/A) (i.e. 'nitrite shunt' biochemistry). This is known to save energy through ceasing oxidation at the nitrite step, but requires careful process control to promote the proliferation of anammox (AMX) bacteria. In this one-year trial, the AMX population took ~200 days to accumulate in the biofilm, from an unseeded bioreactor. The process was maintained by feedback control through monitoring of the gas phase oxygen concentration. Once fully acclimatised oxygen transfer efficiencies above 95% were attained with specific energy consumption values of below 0.3 kWh per kg N−NH3, or <0.4 kWh per kgN removed.

2. Water reuse, including indirect potable reuse (IPR)

It has been recognised for some time that MBRs tend to provide better rejection of pathogens, and viruses in particular, than abiotic membrane polishing. It is nonetheless only recently that credits for the process have been proposed – thanks largely to the extensive WaterVal study in Australia.

The conference presentations based around IPR included:

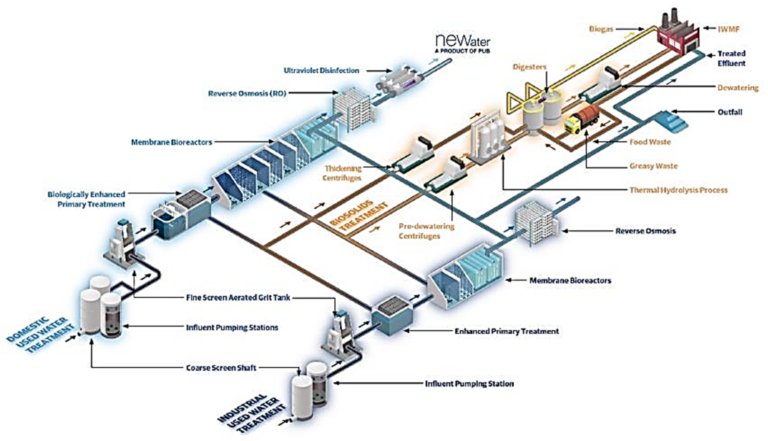

- a summary of the design features of the much-anticipated Water Reuse Plant at Tuas (Fig. 1), which will recover most of the water and resources from 650 and 150 MLD of domestic and industrial wastewater respectively (Zheng, PUB)

- a summary of the outcomes from the Integrated Validation and Demonstration Plant (IVP Demo) pilot study, a demonstration plant for the proposed installation at Tuas (Tao, PUB) – see also our report on the IWA World Water Congress

- a precis of the challenges to implementing MBR technology for direct potable reuse (DPR) in Southern California, which appear to partly hinge on developing analytical methods for detecting microbial and chemical contaminants at very low levels (Liang, Metropolitan Water District of Southern California)

- continuous indirect membrane integrity monitoring through permeate quality measurement, comprising:

- gravimetric measurement of captured solids (Katz, Suez), and

- advanced nephelometric measurement (Rajasekharan, Hach).

3. Industrial effluent treatment

The applications addressed in these presentations included:

- refinery effluent using an IFAS integrated with a downstream MBR, configured as an MLE process with the return sludge from the MBR directed to the anoxic tank upstream of the aerobic tank filled with 50% media (Chee, AECOM)

- zoo effluent treatment for non-potable reuse purposes, based on a pilot trial to establish the attainable water quality with reference to a range of indicator pathogens (Koh, BV)

- dairy and slaughterhouse effluent treatment using a 4m3 demonstration plant comprising an upflow anaerobic sludge blanket clarifier (UASB) integrated with an MBR (Bernat, Suez), the process being denoted SIAM (a Spanish acronym)

- the application of advanced oxidation, based on Fenton’s reagent, both upstream and downstream of an MBR for treating industrial effluent from various sources (Liu, CITIC).

The combination of UASB with a downstream MBR has been previously studied at demonstration scale – in Singapore (naturally). According to the more recent Spanish study, the SIAM process was around 35% higher in capital cost than a conventional activated sludge system, but 44–49% lower in operating costs due to a reduction of the sludge production (over 50%) and the valorisation of the biogas generated. These figures obviously depend on the strength of the wastewater (2600 mg/L for the slaughterhouse effluent, in this instance).

4. Anaerobic processes

Apart from the Spanish demonstration of the UASB–MBR process, there were three further AnMBR studies – all dedicated to municipal wastewater treatment:

- a report of the AnMBR microbial ecology and its relationship to membrane fouling (Hong, KAUST)

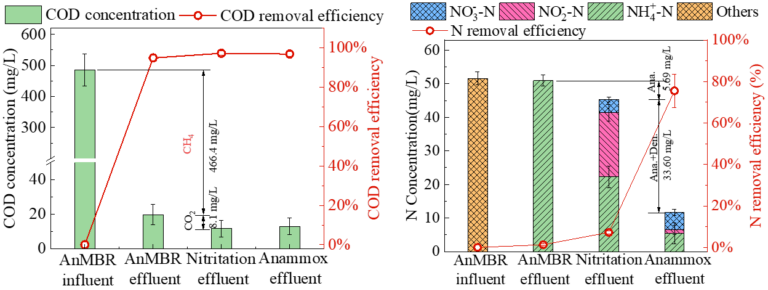

- a bench-scale study of the combination of an AnMBR with a downstream anammox system, comprising an anoxic sequencing batch reactor (SBR) followed by a UASB to remove nitrogen by the nitritation–anammox process (Lei, Xi’an University)

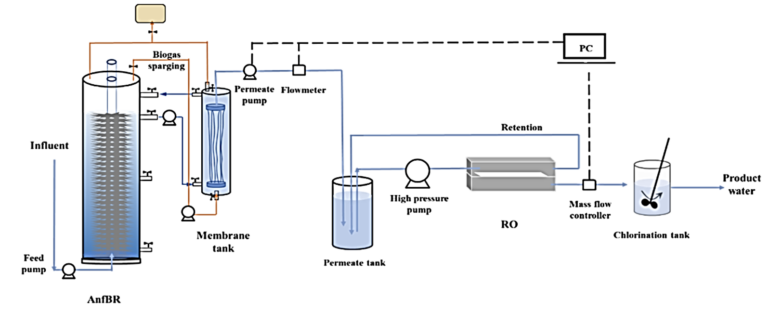

- the integration of an anaerobic fixed-film bioreactor (AnfBR) with membrane separation, with downstream reverse osmosis demineralisation and breakpoint chlorination of the RO permeate (Wang, Nanyang University).

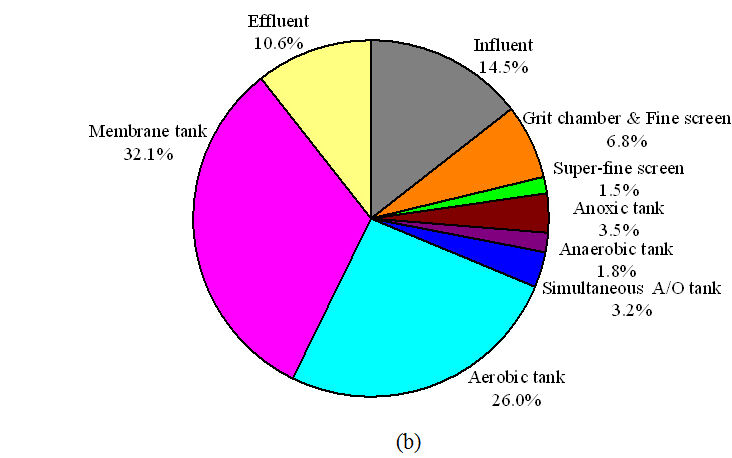

The second of these provided an elegant demonstration of the biochemistry at work at each stage of the An–PN/A process (Fig. 2), with:

- the COD being removed by the anaerobic stage, followed by

- ammonia conversion to nitrite in the partial nitritation stage, and then finally

- nitrite conversion to nitrogen via anammox.

The HRTs of each stage were reduced over the course of the study to establish the optimum value. Values of 12h for the anaerobic stage and 4h for the PN/A stage were reported.

In the case of the Nanyang study (Fig. 3), it was apparently possible to maintain a flux of 20 LMH in the reverse osmosis process downstream of the AnfMBR. Clearly, this sort of approach – as well as that studied at Xi’an University – would need to be demonstrated at a larger scale to establish whether these operating conditions are sustainable outside of the laboratory.

It is interesting to note that, for both the Nanyang and Xi’an studies, as well as the SIAM process piloted for industrial effluent treatment, the membrane is used more as a polishing stage than for filtering the biological sludge, as with a regular MBR. Given the well-recognised high fouling propensity of anaerobic sludge, this would seem to make a lot of sense.

5. Other hybrid/combined processes

In addition to the anaerobic processes, there were a few examples of combinations of the aerobic MBR technology with other unit operations, including:

- polishing of MBR effluent with constructed wetlands (Zhang, CITIC)

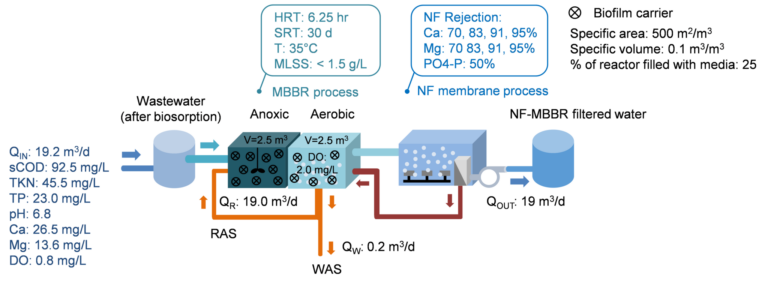

- combination of a bioreactor with a <500 Da hollow fibre nanofiltration (NF) module, followed by downstream polishing by reverse osmosis (Chong, Nanyang University).

Two key challenges to employing NF in place of ultrafiltration/microfiltration for an MBR/MBBR process (Fig. 4) are the accumulation of salinity and sustaining the flux. The Nanyang authors reported an NF flux of 10 LMH from their work at a transmembrane pressure below 2 bar, as well as negligible increase in the mixed liquor salinity.

There were a few other presentations featuring MBRs. These included two by Meiden (Noguchi), the ceramic flat sheet membrane producer, dedicated to OPEX reduction through:

- employing intermittent membrane aeration, producing a potential OPEX saving of over 40%, and

- changes to the module design, and specifically eliminating the permeate extraction tubes, and optimising the chemical cleaning protocol.

The first of these included a CFD (computation fluid dynamics) analysis of the aerated membrane. CFD forms the basis of the work by AM TEAM, some of whose work was presented by Wim Audenaert at the conference and can be found elsewhere on this site.

And finally ..

It would be remiss to round this report off without acknowledging the sterling efforts of the conference organisers, the developers of the online platform, and all the participants – particularly those caught at the wrong end of the time zone shifts to find themselves presenting their work at some ungodly hour in the morning.

The 2021 Singapore International Water Week was meticulously well organised. The whole conference hinged around a portal which allowed delegates to easily click between different sessions, view posters and abstracts, visit the virtual expo, and set up online meetings. Everything ran to schedule – to the nearest second, in fact – and all live platform sessions were recorded from start to finish, and there were 10-minute video presentations of all the posters.

So no excuses for missing out, if you had the time. Over 140 hours of online content was generated by the conference – a marathon viewing session – about the same as watching every episode from all five seasons of The Wire twice over and then doing the same for all the prequels and deleted scenes.