Cowichan Valley, Vancouver Island MBR systemsview Toray

Application:

Municipal

Toray MBR

About Cowichan Valley, Vancouver Island MBR systems

BACKGROUND

In 2006, Toray began a successful relationship with the Cowichan Valley Regional District (CVRD) in beautiful Vancouver Island, Canada. Two membrane bio-reactor (MBR) systems were commissioned that year at CVRD at the Lambourn Estates and the Sentinel Ridge Sanitary Sewer Systems. Both systems incorporated Toray's TMR140 series MBR modules.

The Lambourn Estates system treats an average daily flow (ADF) of 140 m3/day with a peak daily flow (PDF) of 350 m3/day. The effluent is further treated by ultraviolet (UV) then discharged to the ocean. The ADF at Sentinel Ridge plant is 180 m3/day. CVRD later installed several new MBR plants, including Twin Cedars (137 m3/d ADF) in 2007; Woodland Shores (200 m3/d) in 2008; and Arbutus Ridge (350 m3/d) in 2016.

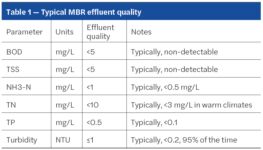

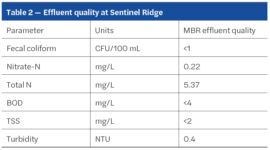

MBR systems are proven to produce a high-quality effluent with a compact footprint, low maintenance, and modular design that makes it easy to upgrade. Table 1 shows the typical MBR effluent quality when treating municipal sewage. An analysis performed in June 2020 at the UV outlet of Sentinel Ridge shows the MBR modules are still producing excellent treated water quality (Table 2).

PERFORMANCE

At Sentinel Ridge, the influent BOD is 350 mg/ L and operates at an MLSS between 9–15 g/L. The only pretreatment includes two equalization tanks that are hydraulically connected and a 2 mm screen. The MBR system operates at an average flux rate of 11 gfd with a transmembrane pressure (TMP) between 1.0 and 1.5 psi and cleaning intervals of once every six months.

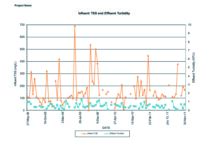

The graph in Figure 4 illustrates the influent and effluent total suspended solids (TSS). Effluent TSS was 1 mg/L on average.

HIGH PACKING DENSITY MBR

In 2016, Toray introduced the 'New High Performance' (NHP) MBR module (Figure 5). The NHP uses the same durable polyvinylidene fluoride (PVDF) flat-sheet membrane of the TMR modules. However, one TMR140-100S module consists of 1,507 ft2 in membrane area, while an NHP210-300S holds 2,260 ft2 in membrane area, giving the NHP module a 50% higher packing density. The additional surface area allows the end-user to treat higher flows or operate at a reduced flux rate. Furthermore, the unique construction of the NHP module has reduced the weight by 70% for easier shipping and handling. TMR modules are easily retrofittable with the NHP.

CVRD installed several of its MBR plants with this latest technology. The MBR system at Arbutus Ridge was able to expand its capacity from 350 m3/d using two rotating biological contractors to 650 m3/d using six NHP210-300S modules. The Twin Cedars plant installed four NHP210- 300S modules by retrofitting the TMR140-100S model and utilizing spare spaces available in the MBR tank. The capacity tripled from 137 m3/d to 450 m3/d. Lambourn Estates also installed four NHP210-300S modules.

- Cowichan Valley, Vancouver Island MBR Systems (PDF 320KB)

Company summary

About this page

This page was last updated on 22 April 2021

Disclaimer

Information on this page may have been supplied by third parties. You are reminded to contact any third parties to confirm information is accurate, up to date and complete before acting upon it. TheMBRSite.com accepts no liability for information provided by third parties, actions taken on the basis of this information or information held on third-party websites.