Sequential anaerobic and microalgal membrane bioreactor for water, energy and nutrient recovery from wastewater

Minh T. Vua, Hang P. Vua, Luong N. Nguyena*, Galilee U. Semblanteb, Md Abu Hasan Johira and Long D. Nghiema,c

a Centre for Technology in Water and Wastewater, School of Civil and Environmental Engineering, University of Technology Sydney, Sydney, NSW 2007, Australia

b Technical Services, Western Sydney University, Kingswood, NSW 2747, Australia

c NTT Institute of Hi-Technology, Nguyen Tat Thanh University, Ho Chi Minh City, Vietnam

*Corresponding author: Luong N. Nguyen: Centre for Technology in Water and Wastewater, School of Civil and Environmental Engineering, University of Technology Sydney, NSW 2007, Australia

E-mail: [email protected]

1. Resource recovery from wastewater

There is increasing interest in the more extensive recovery of resources from wastewater, including its latent energy and nutrient content, alongside the water itself. Wastewater reuse has been implemented for more than two decades, in Singapore in particular where there are currently five full-scale plants in operation meeting up to 40% of the country’s industrial water demand.

Recovery of latent energy as biogas (predominantly methane) is generally limited to anaerobic digestion (AD) of the sludge waste stream, whose primary purpose is to stabilise the sludge solids. The sludge stream provides the necessarily high organic load to make energy recovery by AD economically viable.

Anaerobic membrane bioreactor (AnMBR) technology for treating wastewater directly has formed the focus of research for many years and has been implemented for high-strength industrial wastewaters since the early 1990s. On the other hand, as with AD, it provides only limited nutrient removal.

However, the nutrient content of the AnMBR effluent can be used to feed microalgae – a biomass from which energy (biofuel) can potentially be produced by hydrothermal liquefaction. The algae have been shown to assimilate nutrients from wastewater, providing the dual benefit of wastewater purification and the generation of a useful biomass.

The study we have undertaken aims to evaluate a treatment scheme comprising an AnMBR with a downstream algal membrane photobioreactor (MPBR). The AnMBR performance was assessed in terms of its organic carbon removal and biogas generation.

The nutrient-rich AnMBR effluent was fed directly into the MPBR and the generated algae (Chlorella vulgaris, C. vulgaris) harvested and agglomerated. The MPBR efficacy was assessed in terms of the removal of nitrogen (N) and phosphorus (P).

2. Methodology

2.1 AnMBR

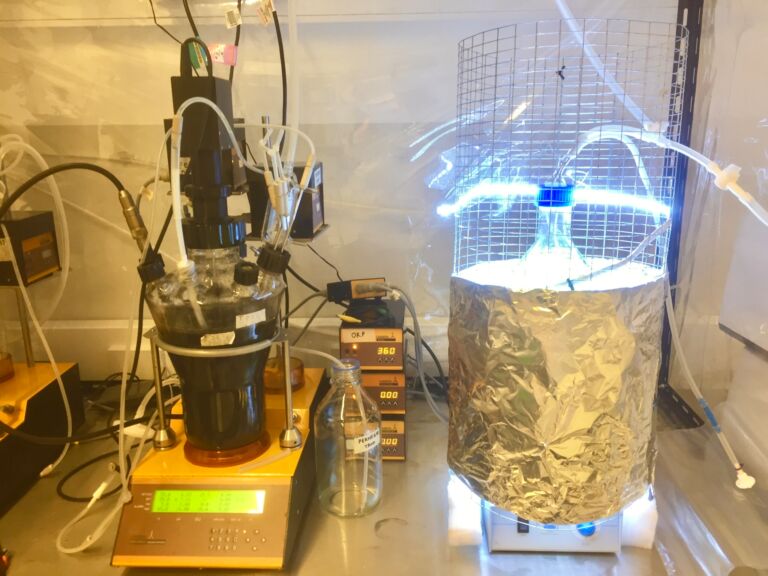

The AnMBR comprised a 3 L glass fermenter containing an immersed hollow fibre (iHF) PVDF membrane of 0.02 m2 membrane area (Fig. 1). It was seeded with AD sludge from a nearby wastewater treatment works and fed with a synthetic municipal wastewater containing 7500, 164 and 66 mg/L COD, NH4+ and PO43- respectively.

Hydraulic and solids retention times of ~24 h HRT and ~80 d SRT respectively were employed, giving an organic loading rate (OLR) of 5.1 kgCOD/m3/day. The mixed liquor suspended solids was in the range 10–14 g L-1, sustained by a net membrane flux of 4.2 L m-2h-1 from operation on a 9 min filtration : 1 min relaxation cycle. The reactor was kept at 35°C, and the biogas generated continuously collected. The biogas volume and content were recorded, specifically the CH4, CO2 and H2 concentrations.

The energy recovery was determined assuming a biogas calorific value of 22 MJ per m3 (or 6.1 kWh per m3) and an electrical conversion efficiency of 35%.

2.2 MPBR

The C. vulgaris was cultivated in the AnMBR effluent in a 1 L vessel, aerated at 1.5 L min-1, held at ~20 °C and irradiated at ~100 µmol photons m-2 s-1 light intensity in a 20:4 h light:dark cycle. This was to allow the algae to adapt to the anaerobic effluent.

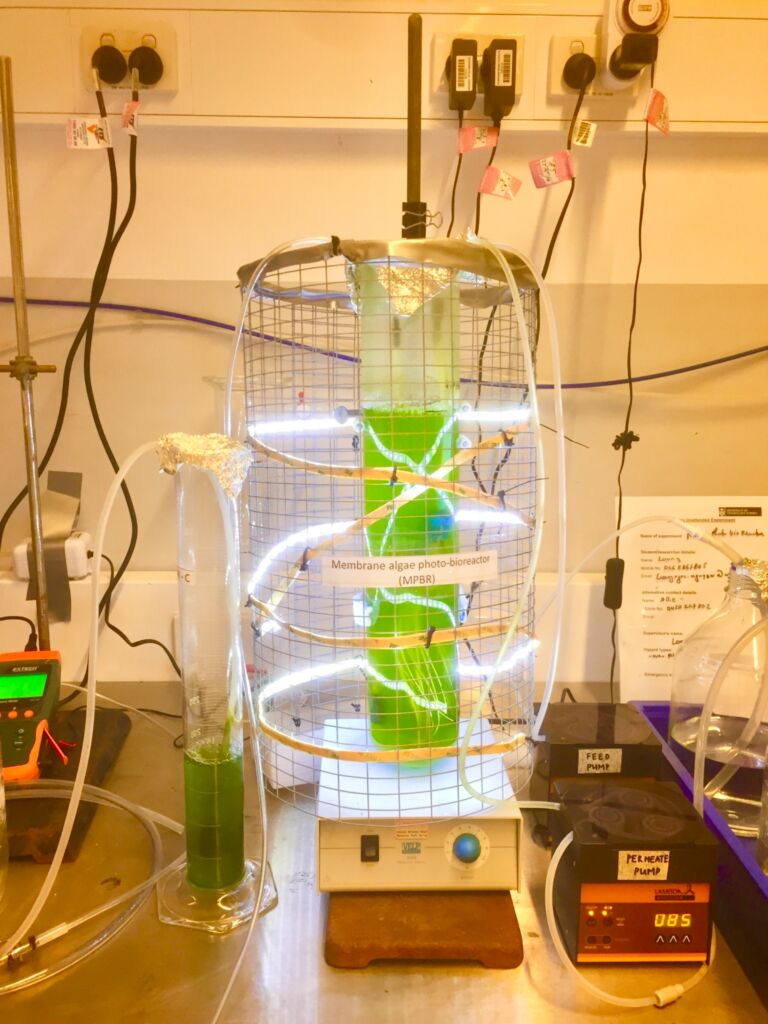

The MPBR comprised a 1.5 L cylindrical glass vessel (Fig. 1) with a second iHF membrane operated at a net flux of 3.15 L m-2 h-1 using the same cyclic operation as the AnMBR, aerated at the rate of 100 L min-1 with filtered air and kept at a temperature of 22–23°C. The initial biomass concentration was 300 mg/L, obtained by 1:50 dilution with the AnMBR effluent, and the reactor sustained by the same illumination protocol as for the cultivation stage.

The AnMBR effluent was continuously fed to the MPBR at a rate of 1.5 mL-1, giving an HRT of 24 h and an OLR of around 0.16 kgCOD/m3/day, and operated at an SRT of 30 d. The MPBR was operated for duplicate periods of 13 d.

The harvested algal biomass was dosed with polyacrylamide polymer to allow the flocculated algal solids to be collected by sedimentation.

3. Results and discussion

3.1 AnMBR

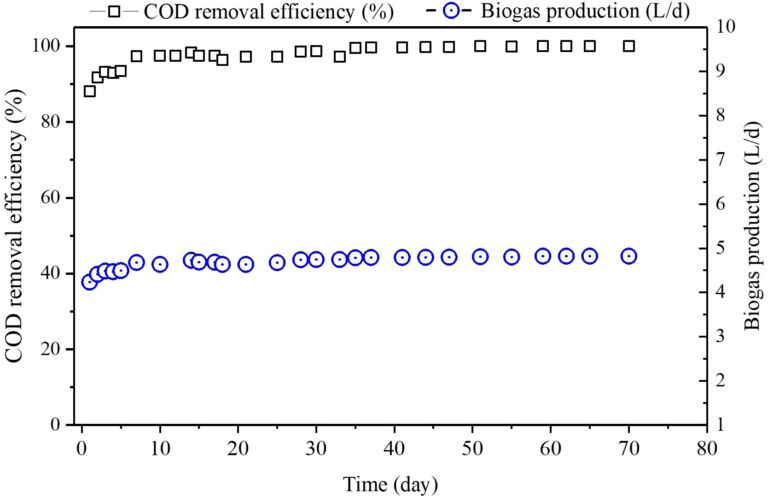

The AnMBR removed >97% of the feedwater COD whilst generating 4.7±0.15 L/d of biogas on average with a 64% methane content (Fig. 2). This equates to 0.3–0.5 L biogas and an average of 0.19 L methane per g COD removed – just over half the theoretical maximum potential of 0.35 L CH4/g COD.

The methane production value is somewhat higher than that expected from anaerobic digestion of primary or mixed primary and secondary sludge because of the high readily biodegradable organic carbon content of the synthetic wastewater. The figure equates to an energy production rate of 2.4 kWh/kg COD per day.

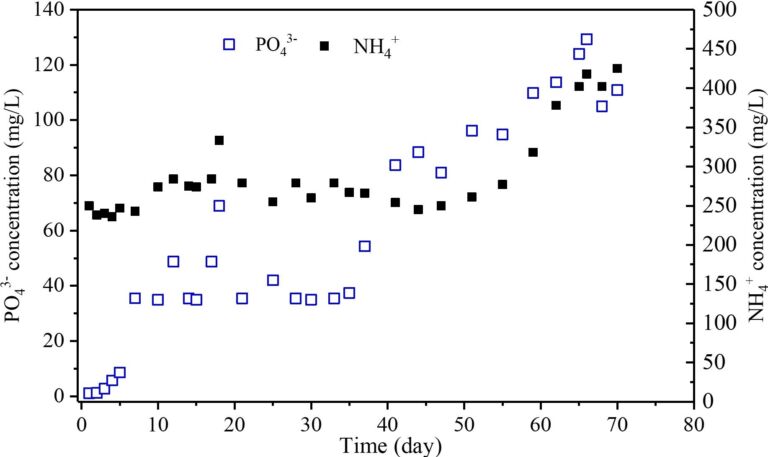

The AnMBR produced effluent containing NH4+ and PO43− concentrations which were respectively 1.9 and 1.4 times those of the influent. The concentrations gradually increased with time (Fig. 3), reflecting the relatively slow prevailing anaerobic biochemistry.

3.2 MPBR

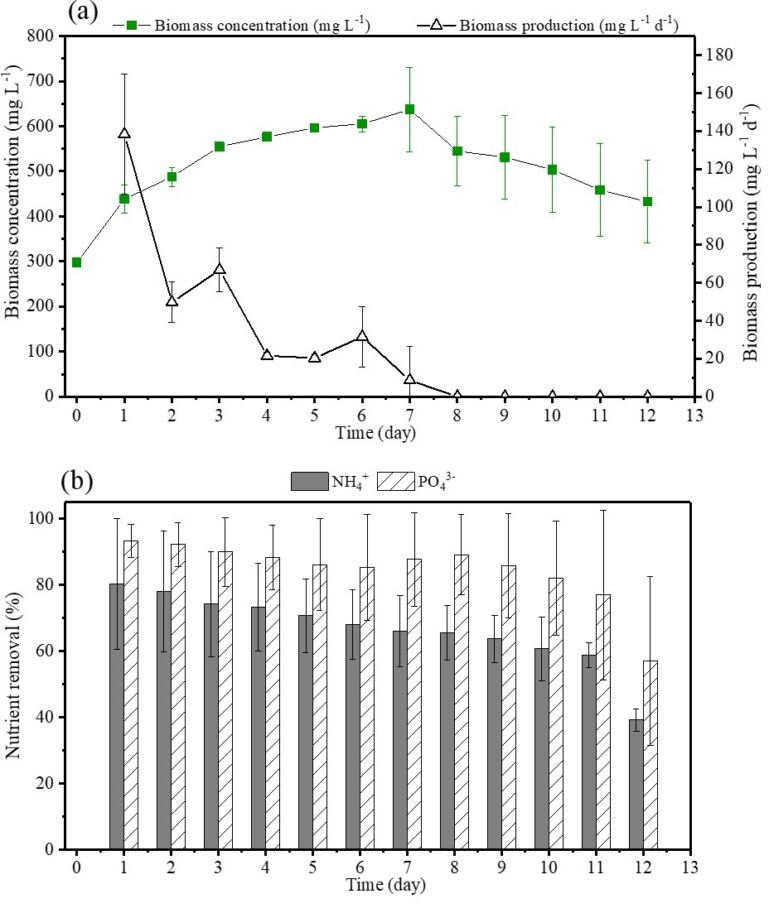

Algal biomass concentration ranged from 450 to 700 mg/L over the 12 days of operation, steadily increasing over the first six days before declining thereafter (Fig. 4a). The production rate decreased from an initial value of ~140 mg/L/d to zero after 8 days.

This continual decline in productivity is most likely to be due to the low HRT of 24h employed for the MPBR. Previous studies of the same algal species indicate retention times in excess of two days. It is also the case that, as with regular wastewater treatment, effective removal requires nutrient balancing, i.e. an appropriate C:N:P ratio.

It is possible that balancing with carbon could be achieved by directing the biogas from the AnMBR stage to the MPBR since this stream is rich in CO2. However, this causes acidification of the algal biomass and partial loss of the methane, which is partly solubilised.

The decline in productivity was reflected in the nutrient removal data (Fig. 4b), for the ammonia in particular. Whilst P removal was sustained at above 80% for the first 11 days, N removal steadily declined from ~80 to ~65% over the same period. For both nutrients there was a significant decline in removal on Day 12.

The nutrient removal data would appear to indicate continued nutrient update by the algal biomass through bioaccumulation without bioassimilation, since the latter would be expected to sustain growth.

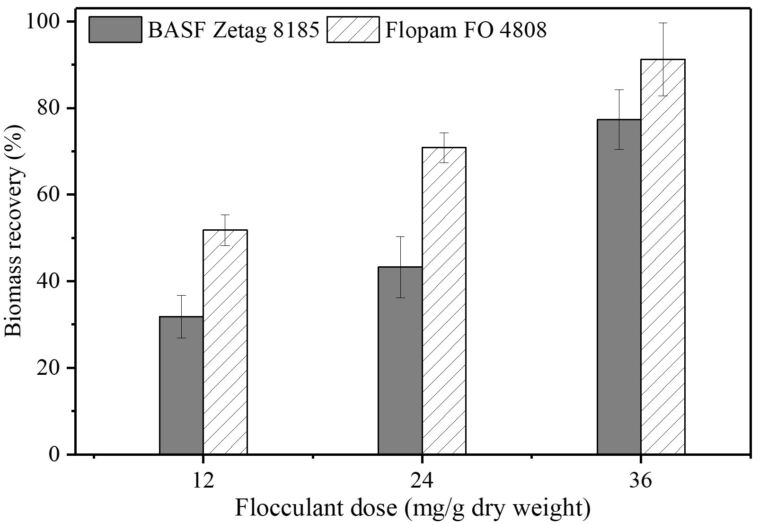

The microalgal biomass was effectively harvested from the reactor by dosing with 36 mg/g dry weight of commercially-available cationic polymer (Fig. 5). Dosing at this concentration recovered 80–90% of the biomass as rapidly settleable solids – the video below demonstrates polymer dosing for recovery of algal solids from biomass.

Algae harvesting

4. Conclusions

This study is still in the early stages, but the initial results suggest that:

- an anaerobic immersed membrane bioreactor (AniMBR) can effectively harness the latent energy of a high-strength wastewater, achieving a specific energy production of 2.4 kWh kg-1 COD(feed) d-1;

- the AniMBR can consistently remove 97% of the feed COD concentration for a wastewater containing readily biodegradable organic carbon;

- the high levels of nutrient in the AniMBR effluent, resulting from anaerobic metabolism, can potentially be used for microalgal culture in a downstream membrane photobioreactor (MPBR), but optimisation of the operating conditions is required to ensure the process is sustainable over an extended period;

- the algal biomass can be effectively harvested, recovering 90% of the biomass on average, using commercial cationic polymers.

Further work on the treatment scheme is ongoing, with the focus on optimising the MPBR to create a viable two-step process for water, energy and nutrient recovery.