Designing and managing wastewater treatment plants using CAE software − the LynxASM1 modelling and simulation tool

Héctor Rey

- Technician in Design and Operation of Wastewater Treatment Plants based on Modelling and Simulation (WEST/LynxASM)

- Process Specialist in the engineering company Prointec

- Lecturer in the Laboratory of Bioindication and WWTP Process Control, Research Institute of Water and Environmental Engineering, Polytechnic University of Valencia, Spain

***UPDATE January 2025***

Since this article was written, unfortunately, the LynxASM1 software is no longer available as a free download. This article has been updated to reflect this. Please note The MBR Site is not responsible for any product or service offered by a third party.

1. Introduction

There was a time, not so long ago, when just about everyone was using spreadsheets as a tool for designing and managing their WWTP. Twenty years ago, the more sophisticated CAE (computer-aided engineering) tools for designing and optimizing wastewater treatment plants were expensive, difficult to use and almost exclusively used by universities and research centres.

Nowadays, however, ever more versatile, sophisticated and accommodating options for designing and managing plants are being developed. So just like the gradual shift from the horse-drawn carriage to the modern motor car, more advanced tools are now increasingly replacing the use of spreadsheets as people begin to appreciate their potential. And as the new tools become more accessible and widespread in their use, the suppliers continue to develop and refine the tools, so the reliability of their predictions increases − promoting further take-up.

So perhaps it’s time to consider putting away that trusty spreadsheet for good and consider CAE methods more closely …

CAE software The MBR Site

2. Alternative computer-aided engineering (CAE) approaches

CAE tools are usually based on one of three different approaches:

- computational fluid dynamics, capable of calculating velocity and pressure fields within the plant facilities. These tools are able to analyze the flow behaviour under different operating regimes or conditions (aeration, treated flow rate, power of the pumps ...)

- multivariate statistical analysis, for example, distance-based lineal models (DISTLM). DISTLM is a routine for analyzing and modelling the relationship between a multivariate data cloud, as described by a resemblance matrix, and one or more predictor variables.

- modelling and simulation, in which the system variables are represented mathematically. This enables the user to compare different design solutions in terms of performance with respect to specific objectives such as effluent quality, investments and operational costs, with a calibrated and validated model.

WWTP ‘modelling and simulation’ is the most widespread and well-known of the above and represents the approach of many commercial CAE packages such as Biowin and WEST. These models are based on the mathematical expression of the common fundamental physical and biochemical processes that form the basis of the secondary treatment stage of a WWTP, and the activated sludge process in particular.

3. Working with ‘modelling and simulation’ CAE packages

The different CAE software simulators available today are generally designed to be user-friendly and demand only a cursory knowledge of fundamental biological process principles, although it is an advantage to know the theory of activated sludge modelling (as originally developed by the University of Cape Town).

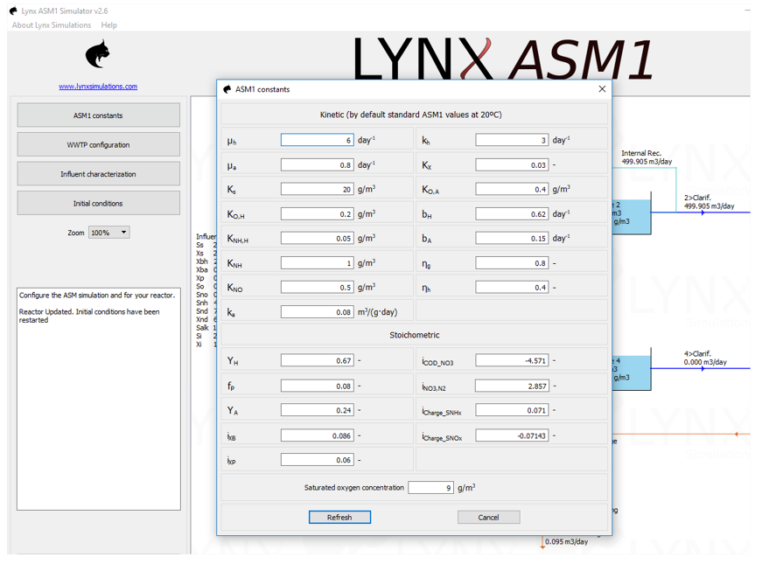

Many of these packages − including LynxASM1 (more of which later) − provide base values for the fundamental biochemical and biokinetic parameters along with those relating to the physical separation component, and these can all be adjusted by the user. Clearly, it is useful to understand the significance of these parameters. The resulting equations based on these parameter values are subsequently solved by numerical methods to provide key outputs such as the treated wastewater quality, aeration demand, recirculation rates and dry solids content.

Although originally developed for the classical activated sludge (CAS) process, modern CAE packages for wastewater treatment can be used in the design and management of many other biological treatment processes, including MBRs and fixed film processes, such as MBBRs (moving bed bioreactors). As with all modelling, the precision and accuracy of the outputs depends on that of the inputs: the well-known ’GIGO‘ principle (‘Garbage In Garbage Out‘) applies here too.

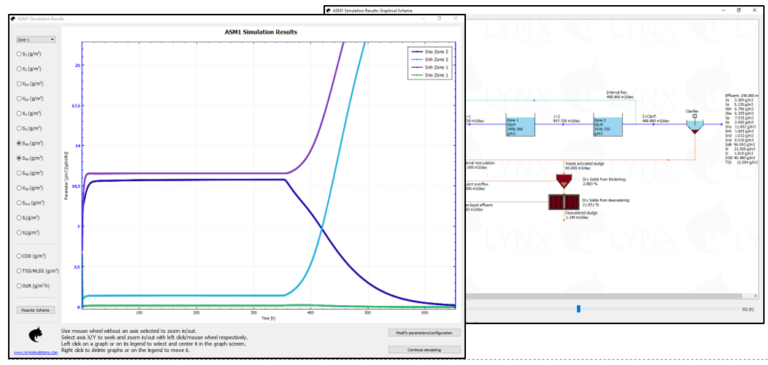

WWTP modelling and simulation software allows users to work with dynamic influent scenarios, as in real life where the feedwater quality may change seasonally, diurnally and/or as a result of ’events‘. A model which has been properly calibrated by reference to real data allows the performance of a specific plant to be properly represented and predicted, differentiating it from other (possibly neighbouring) plants through precise characterization of the influent. It’s also possible to accurately represent the behaviour of the biological reactor, which may differ from that expected according to the technical literature based on normal operation.

The use of historical data to calibrate the model increases the reliability of the predictions made by the model, and therefore reduces the usual safety margins that apply to design based on a standard spreadsheet. This in turn reduces the associated costs for a new-build or retrofit − provided the data used for calibration is appropriately representative.

4. Spreadsheets versus CAE packages: representation of MLSS

Standard spreadsheets can be inflexible and often do not always reflect reality. Your spreadsheet may indicate that an MLSS (mixed liquor suspended solids) of 4,000 ppm MLSS in the reactor can provide an effluent ready for bottling and serving up in a Michelin star restaurant. In reality, it may not be possible to reach more than 1,500 ppm MLSS, due to the nature of the incoming feedwater and the plant operating conditions, leading to incomplete nitrification and an inevitable breach of the nitrogen discharge consent/permit.

The MLSS is usually a key value to be inserted into spreadsheets, of the same significance as operational parameters like ‘recirculation pump flow rate’ or ‘aeration setpoint’. However, the reality is that the MLSS is a consequence of operation and not an imposed control parameter such as a pump speed or the point at which the blower is switched on or off. It is dependent on the biochemistry and biokinetics, which are in turn dependent on factors such as the influent flow and characteristics, the plant operation (and specifically the solids retention time) and temperature.

The value of MLSS is thus a consequence of a host of other factors, some of which can be manipulated by the plant manager, such as the sludge wastage rate, and others which cannot, such as the influent quality and flow rate. However, when using spreadsheets, the value of MLSS is very often necessarily selected by the user to determine the required operating conditions based on average flows and loads. In reality, instantaneous flows and/or loads, or unseasonably extreme temperatures, may render the target treated water quality unobtainable and consequently lead to a breach of the discharge limits. Flow and load variations are in fact a feature of any wastewater treatment plant. Calculations based on spreadsheeting thus always represent a compromise, since either averaged and/or the most challenging conditions are entered on the assumption of steady-state conditions.

5. CAE in practice: The LynxASM1 model

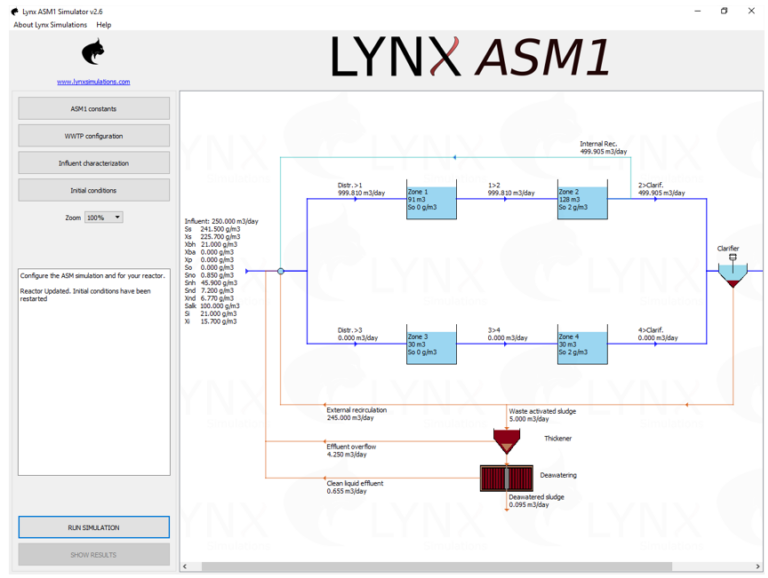

One particular CAE tool, LynxASM1, was developed in a task group by the company Lynx Simulations.

This software was originally developed as a complementary tool to accelerate other Computational Fluid Dynamics (CFD) studies focused on modelling the fluid dynamic and biological processes which take place in WWTP reactors.

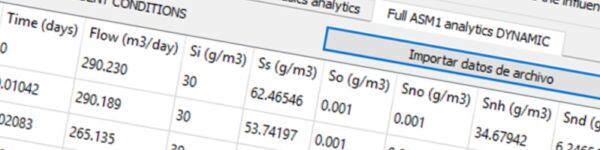

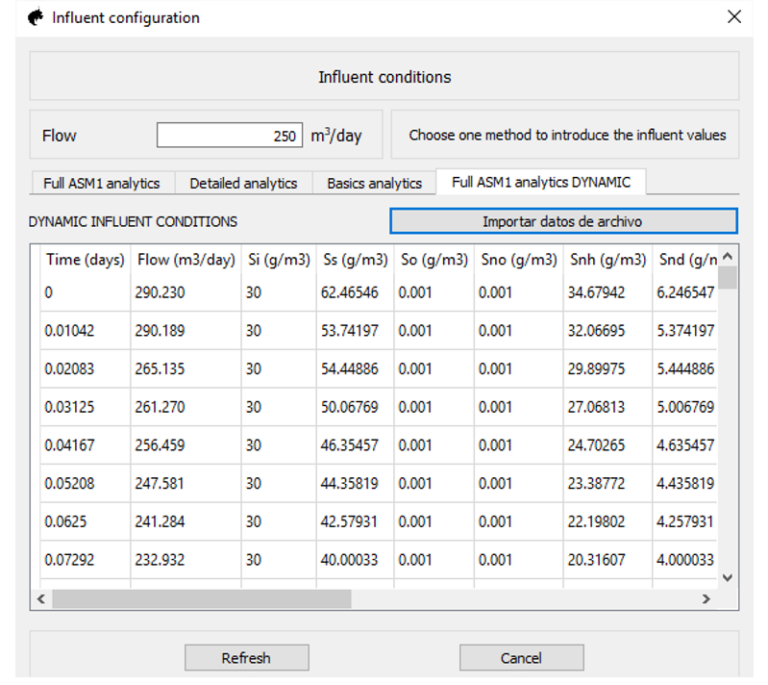

The main aim of developing LynxASM1 was to achieve a program that produces reliable results by simplifying and calibrating actual operating data, rather than just replicating the classical biochemical expressions for the processes of nitrification and denitrification. In the LynxASM1 model, a major advantage is that the user is able to create his or her own specific operating scenario and to optimize it. The LynxASM1 software includes the option of introducing a dynamic influent, and the flows and corresponding substrate concentrations can be entered for specific elapsed time periods (see Fig 4).

6. Summary

CAE software for biological process design is now used widely across the water industry. It has become increasingly accurate, can be applied to a diverse number of processes and integrated with other key design aspects such as costs.

While spreadsheeting is always likely to be used to allow the input of user-determined algorithms – and iterative calculations made possible, for example via the 'goal seek' option in MS Excel − CAE packages are becoming easier to use and are increasing in functionality and accuracy, which means that they are likely to stay around for the foreseeable future.

So, is it finally time to say goodbye to your spreadsheet?