Cleanfil-Ssupplier page

Module product series:

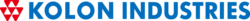

- Cleanfil-S40V

- LENA (Low Energy No Aeration) system

About Cleanfil-S

CleanfilTM-S is a braid-reinforced PVDF hollow fibre membrane which:

- has outstanding tensile and anti-peeling strength

- is free of wetting agent, allowing easy storage & installation without requiring rinsing

- has a high packing density, and so a small footprint

- has a low air consumption.

CleanfilTM-S has been installed at more than 400 sites over 10 countries since 2006. The largest (max. capacity) reference is a 90,000 ㎥/day STP.

The new LENA (Low Energy No Aeration) technology for MBR systems requires no membrane blowers; horizontal reciprocation of the membrane cassettes using a motor and crank generates inertial force of the hollow fibre membranes.

The LENA system prevents sludge accumulation within the fibres more evenly than using an aerator in the membrane cassette, and reduces the energy consumption of conventional air scouring by around 75% compared to a conventional MBR system. It can also achieve a low TN value through increased denitrification efficiency.

Module product series:

- Cleanfil-S40V

- LENA (Low Energy No Aeration) system

†The packing density describes the amount of membrane packed into a given space. It can be defined with reference to both the footprint and the volume: APD - The unitless ratio of the module membrane area to its footprint, where the footprint is defined as the cross-sectional area at the module base; VPD - The membrane area per unit module volume, which has units of m2 per m3 (or m-1) and equates to the APD value divided by the module height.

MBR Case studies and specifications

- Pdf Product Kolon Cleanfil (PDF 3.2MB)

Company summary

About this page

This page was last updated on 04 March 2019

Disclaimer

Information on this page may have been supplied by third parties. You are reminded to contact any third parties to confirm information is accurate, up to date and complete before acting upon it. TheMBRSite.com accepts no liability for information provided by third parties, actions taken on the basis of this information or information held on third-party websites.