Monteray Shores wastewater treatment plantview Toray

Application:

Municipal

Toray MBR

About Monteray Shores wastewater treatment plant

CHALLENGE

The City of Corolla is a popular beach destination located on the northern end of the Outer Banks in North Carolina, and the Monteray Shores Wastewater Treatment Plant (WWTP) treats wastewater generated in the region. The original WWTP consisted of an extended aeration plant using a circular tank with a central clarifier to handle a maximum hydraulic capacity of 180,000 gpd and remove BOD, TSS and NH3. Due to increased tourism and residential developments, the WWTP faced challenges meeting treatment capacity and new effluent limits for nitrogen and phosphorus, particularly during fluctuations experienced between the different seasons.

Furthermore, existing residential and commercial developments surrounding the WWTP restricted the space required for expansion. However, state regulations allowed for reduced restrictions for implementing treatment systems that produced high-quality reclaimed water, including low levels of total nitrogen (TN) and phosphorus (TP). Evaluations revealed that a membrane bioreactor (MBR) process was the best alternative for meeting all of the plant's requirements of treatment capacity, effluent quality, and system footprint.

The MBR system would increase the capacity by 189% to treat influent flows from 0.18 MGD up to 0.52 MGD during the peak summer months.

MBR PROCESS

The selected MBR process uses Toray's flat-sheet membranes made of a durable PVDF (Polyvinylidene fluoride) material with 0.08 μm pore size, which would purify the wastewater to high-quality standards effectively reducing, BOD, TSS, TN and TP.

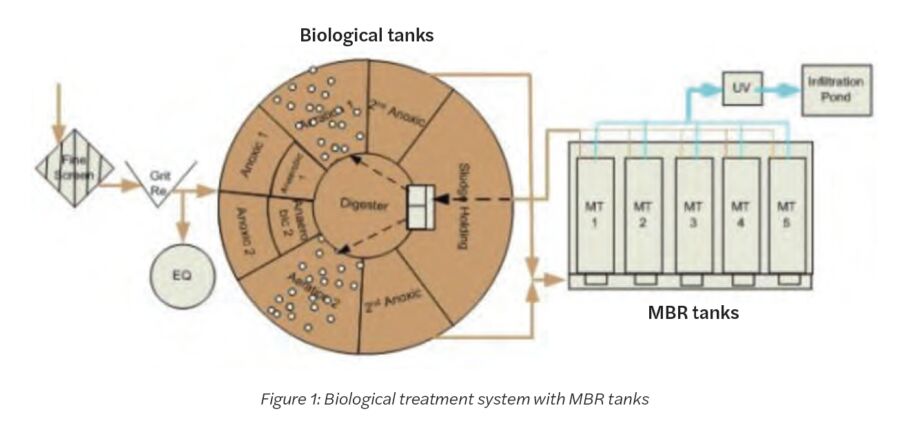

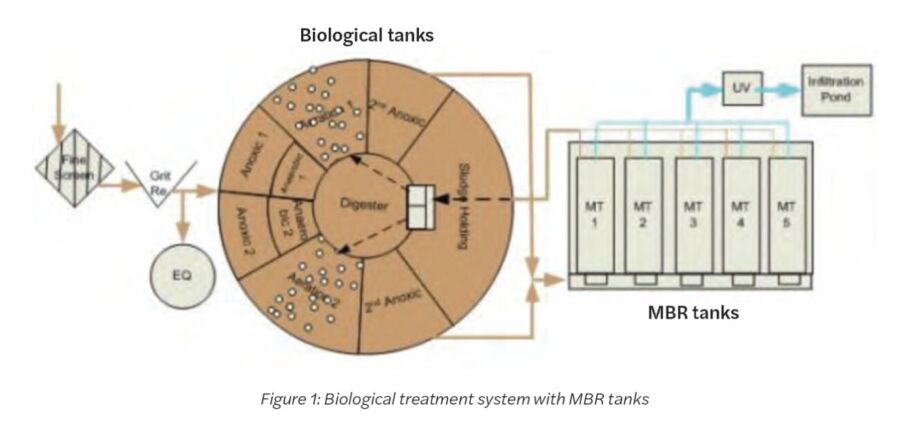

The existing aeration plant was to a four-stage biological treatment process comprising anaerobic, primary anoxic, aeration and secondary anoxic zones, and five MBR tanks were added downstream, significantly reducing system footprint. Each MBR tank is complete with a dedicated permeate pump, scour aeration blower and return activated sludge pump, and space available for a sixth module if needed for expansion.

The MBR system increased the treatment capacity by 189% to treat influent flows of up to 520,000 gpd in summer during the peak tourist months and down to 50,000 gpd during the low flow season in winter.

The new MBR facility came on-line in 2009, and over ten years later, the staff at Monteray Shores WWTP continue to operate this MBR system successfully with minimal impact on the environment and surrounding communities.

Key Benefits

- MBR trains can be taken on and off-line depending on the season to conserve energy and equipment lifetime.

- Reduces TN and TP to less than 4 mg/L and 2 mg/L, respectively, and approved by the state of North Carolina Department of Environment and Natural Resources (DENR).

- Treated effluent is of reclaimed water quality.

Company summary

About this page

This page was last updated on 22 April 2021

Disclaimer

Information on this page may have been supplied by third parties. You are reminded to contact any third parties to confirm information is accurate, up to date and complete before acting upon it. TheMBRSite.com accepts no liability for information provided by third parties, actions taken on the basis of this information or information held on third-party websites.