WEFTEC 2023 - a report

Simon and Claire Judd

Owners/managers of The MBR Site and SludgeProcessing.com, and Directors of Judd Water & Wastewater Consultants, based in the UK

WEFTEC 2023

WEFTEC 2023 was held in Chicago, Illinois from 30 September to 4 October, with the exhibition component held on three of these days. This was our second visit to the Water Environment Federation's Technical Exhibition and Conference, the first being in New Orleans back in 2018. We only attended the exhibition this year so are unable to comment on the conference, but it was good to get out into the big wide world again post-COVID to meet both familiar and new faces in the areas of water and environmental management.

From our two days at the Exhibition, our overall sense was that the sector is bouncing back from the pandemic. A number of people reported that projects put on hold during lockdown and during the international travel ban now seem to be rising up the agenda again. The general tone was positive and optimistic.

The WEFTEC Exhibition

The exhibition at the McCormick Place Convention Centre in Chicago is massive and mostly fills two large halls with hundreds (more than 800, according to the organisers) of exhibiting companies. It’s obvious from the amount of effort the teams put into marketing their space, and hosting talks and workshops on the floor, that they consider WEFTEC to be an important event - if not the most important - at which to showcase their wares.

On the sludge processing side, there were quite a few gleaming examples of dewatering technologies, most noticeably centrifuges, screw presses and belt presses. As well as the full-scale equipment there was more than one scale model belt press on display in the exhibitor booths - each one probably around one tenth the size of the full-scale plant. In at least one case, the scale model was fully operational – an obvious labour of love and doubtless coveted plaything for any infant water engineer. There were, naturally, also a large number of membrane modules, cassettes and skids on display from the various membrane suppliers.

Of the 35-or-so exhibitors we spoke to, many commented that – encouragingly - footfall this year seemed to be back up to pre-pandemic levels, and that WEFTEC 2023 had been a crucial opportunity to link in with existing and potential clients.

Product launches

Perhaps understandably, there did not appear to be a large number of new product launches, and only a few noteworthy adaptations of existing products, that we came across during our wanderings (though we only visited around 35 booths in total). A few examples of new developments are listed below.

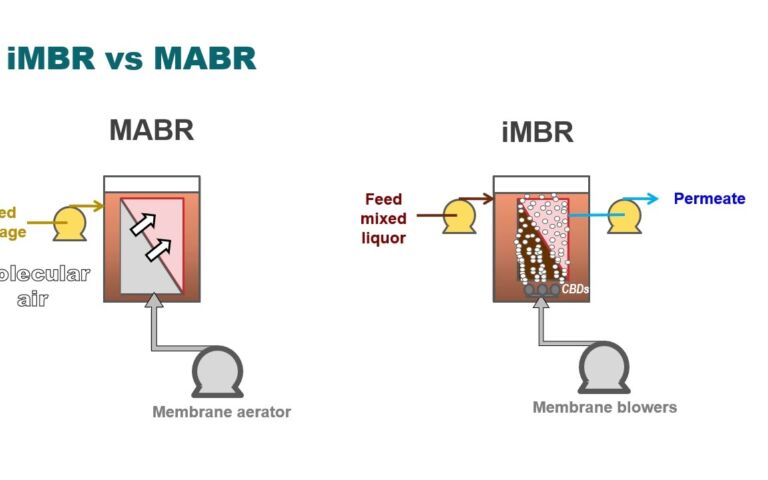

- The new ZW500EV module from Veolia, which offers a 19% increased module area and a similar decrease in normalised air scour demand (in Nm3/h per m2 membrane area) compared with the ZW500D. The EV cassette contains some mechanical modifications to improve air scour efficiency by directing more of the air into the fibre bundle. Veolia have also introduced a hydrocyclone step to their MABR process for selectively recovering the active cells for returning to the biological stage (zeeDENSE).

- The Du Pont B50N module, which at 50 m2 per module (25% more than the B40N) implies a total membrane area of 800 m2 for a 16-module rack and, if our maths is right, just shy of 790 m2 per m2 rack floor area.

- The Ovivo electrochemical oxidation technology for PFAS, which actually mineralises the PFAS to the constituent carbon dioxide, fluoride and water. The oxidation step is applied to either the eluate from an adsorption media or the retentate of an RO separation step used to pre-concentrate the PFAS to increase the percentage removal and energy efficiency of the destruction step. The technology was developed over the past two years in collaboration with e2metrix, who have produced the ECOTHOR® platform for electrochemical oxidation, disinfection and coagulation. The product was launched at a separate Ovivo customer event at the very picturesque Navy Pier region of Chicago.

Emerging themes

From conversations with exhibitors, a few general themes arose which probably merit a mention:

PFAS legislation. Almost inevitably, given the pronouncement from the EU legislators earlier this year, the prospective classification of PVDF as PFAS was discussed by a number of suppliers of PVDF membranes. Apparently, several companies have already submitted individual cases for derogation or exclusion from the legislation. The stakeholder consultation was scheduled to end on 25 September, so presumably all such relevant submissions should have been made by now.

US government funding for US-produced engineering and technology. The ‘Made in America’ initiative is designed to increase the robustness of domestic supply chains in the US and reduce the need to import goods from overseas. A few suppliers seem to have taken advantage of the available funding to help bring new products to the market.

Importance of degritting. An interesting point was made about grit removal, or rather the downstream consequences of failing to remove it (abrasion of pumps and flow channels, filling of aeration channels and AD with inerts, and possible damage to membranes). The economic impact of this is a topic which has featured on The MBR Site previously, and it’s encouraging to learn that some of the more advanced vortex separation devices seem able to resolve ever smaller grit particles from the more neutrally buoyant suspended organics needed to sustain the process biology.

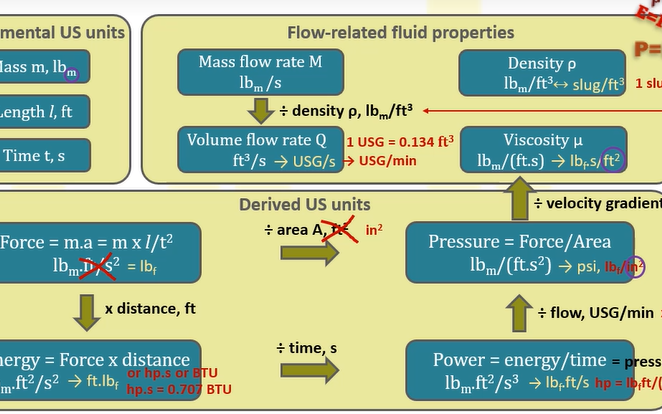

Emphasis on training. More than one of the exhibitors bemoaned the lack of training - or possibly education generally - within the sector. It seems that, whilst process technicians and operators are able to demonstrate commendable specialist knowledge of the installations for which they are responsible, this does not necessarily mean that they have grasped the process technology principles and the interdependency of the unit processes in the treatment train. The most obvious manifestation is in the logging, calculation and interpretation of key process performance determinants - such as SVI, SRT, F:M ratio, EPS levels and filament index. These things are fundamentally important in determining the process efficacy, but not often comprehensively monitored and perhaps not widely understood.

The MBR membrane replacement market. There appear to be quite a few examples of the replacement of an existing immersed membrane technology with an alternative one - including replacing hollow fibre (HF) technologies with flat sheet (FS) ones and vice versa. This suggests that, whilst the footprint incurred by these two immersed systems would be expected to differ based on the module specifications for the main FS and HF products, this does not seem to preclude interchangeability in practice. There are also plenty of instances of upgrading of rigid panel FS products with composite ones. Examples include the Cowichan Valley Regional District of Canada where four sites have changed out the Toray rigid TMR membranes ("flat plates") to the same suppliers’ NHP composites ("flat sheets") to provide increased treatment capacity.

Global view. A couple of suppliers mentioned that they were starting to lift their gaze above solely the US market to take a more global outlook. The Asia Pacific MBR market is estimated by some market analysts to already exceed that of the US market, with this difference likely to expand in the future.

Exhibitors visited

From our two full days pounding the trade show floor, we chatted with exhibitors from over 35 companies purveying MBR technologies and/or sludge processing equipment, including (and with profuse apologies to anyone we've inadvertently omitted):

- Alfa Laval

- Anaergia

- Andritz

- BDP Industries

- Berghof

- bioprocessH2O

- Bright Technologies

- CAMBI

- CCI Bioenergy

- Cerafiltec

- Centrisys cnp

- Charter Machine Company

- CWT Clean Water Technology

- Dongjin Industrial Machinery

- Du Pont Water Solutions

- Elode

- Fibracast

- Fluence

- GEA Group

- H2O Innovation

- Hifilm Inc

- Huber

- Innovatreat

- Komline-Sanderson

- Kubota

- Lystek

- MANN+HUMMEL

- Merrell Bros

- Nijhuis Saur Industries

- Ovivo

- Schwing Bioset

- Smith & Loveless

- Toray

- Unisol Membrane Technology

- Veolia Water Technologies

- Vogelsang

It was a pleasure to meet everyone, whether at a booth or off-piste in the café (most notably Transcend and MMBR). Many thanks to all for the earnest and honest discussions; it’s always an education. Happily, we also bumped into two alumni of Simon’s former stomping ground at Cranfield University Water Sciences - Divya Inna and Diego Ayala (respectively of BlueTech Research and Kubota Membranes) – to whom thanks are also due for the further insights provided.

Wrapping-up

WEFTEC 2023 appeared to be very well and enthusiastically attended - unsurprisingly given the constraints on such events imposed over the preceding three years. As with pretty much every other sector, there has been a collective sigh of relief within the water industry at the release from the shackles of lockdown, allowing major international events such as WEFTEC to go ahead on the conventional pre-pandemic basis. Online communication tools may have become very sophisticated and ergonomic, but there’s really no substitute for shaking someone’s hand and commenting on their displayed goods, corporate identity and/or dress sense.