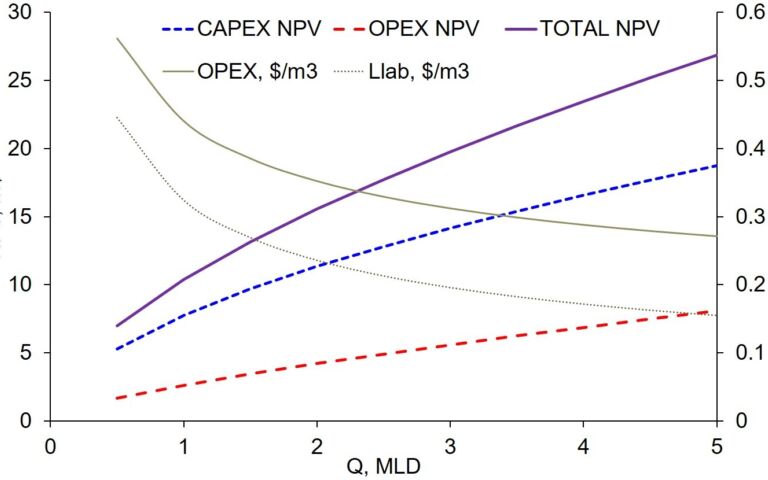

MBR costs − an overview

The key components of OPEX are the energy consumption, staffing requirements, membrane replacement, chemicals consumption, and waste management and disposal. The most significant of these is the energy consumption, primarily from aeration.