What can go wrong in an MBR?

MBR challenges

There are many advantages to membrane bioreactors over other wastewater technologies, but they can also be more challenging. The key disadvantage of MBR technology, which directly or indirectly impacts on their cost, relates to their design and operation.

As with most other wastewater treatment processes, a design which is not conservative enough will normally impair the routine operation of the plant. This may result in a number of generally recognised technical challenges (see Operation and maintenance − MBR fouling, clogging and cleaning):

- membrane surface fouling

- membrane channel clogging

- membrane chemical cleaning

- membrane aeration.

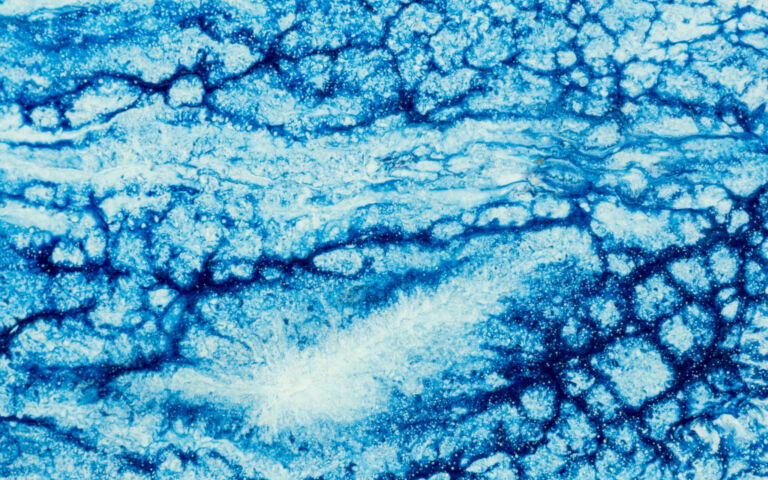

Fouling and clogging

Fouling and clogging may be associated with an overly ambitious design flux. Clogging may also be associated with under-specification of the screens, the screens being part of the preliminary treatment and offering the main barrier to coarse solids. Because additional fine screening− down to 1 mm or less in some cases − is required to protect the membrane separation process, the amount of waste (screenings) generated by the preliminary treatment can be significant.

Chemical cleaning

Effective chemical cleaning of the membrane means that it is necessary to identify the appropriate combination and concentration of cleaning chemicals. Cleaning is normally accomplished through application of hypochlorite and citric/mineral acid, either individually or sequentially.

The precise, most effective cleaning protocol is often arrived at through trial-and-error, and is influenced by process operational factors such as the flux and the sludge/mixed liquor quality. This complexity makes identifying the optimum cleaning protocol somewhat challenging.

Membrane aeration

Air scouring of the membrane is pivotal in maintaining the cleanliness of the membrane. Uneven aeration of the membrane modules can lead to rapid fouling and clogging of those areas not receiving sufficient air scouring. The aerators must therefore be either cleanable or designed so as not to clog.

Other challenges

Other challenges to MBRs include automation/process control and operator knowledge. The operational complexity of the process compared to a CAS implies more extensive automation and control.

The complex nature of the process is often beyond the knowledge base of the operators in regions where MBR technology is newly introduced, so appropriate training is essential.