Sludge pumping costs in MBRs

Sludge pumping costs in MBRs

Sludge transfer is normally the second most significant contributor to MBR energy demand after aeration.

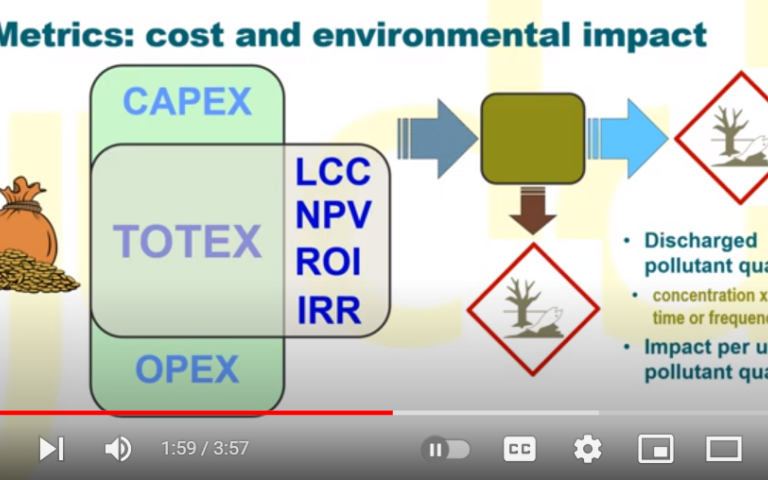

Costs deriving from sludge pumping or transfer from the membrane tank to the process tank, and between different regions within the process (for nutrient removal), are primarily a function of the pumping rate.

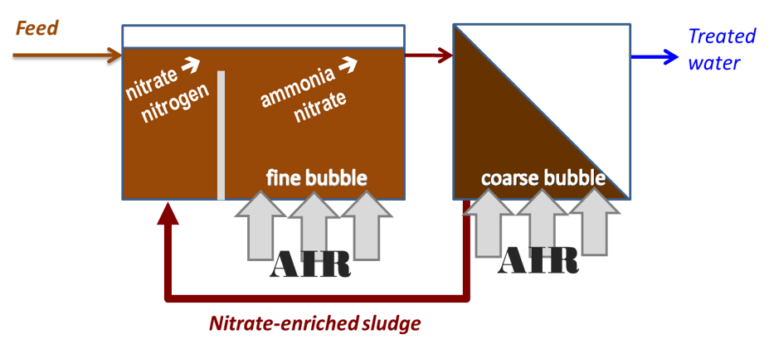

Nutrient removal (nitrate and phosphate, usually abbreviated to N and P respectively) is essentially brought about by pumping the sludge to different tanks or regions of tanks where different oxidation conditions prevail, allowing conversion of nitrate to nitrogen gas ('denitrification'). This modification, known as the ‘Modified Ludzack−Ettinger’ process (MLE), then affects the OPEX in two ways.

Firstly, additional energy is required for transferring sludge between the two regions. Secondly, the oxygen demand is reduced since some of the oxygen required for ammoniacal nitrogen oxidation to nitrate (nitrification) is supplied by the nitrate.

For biological phosphorus (P) removal, further pumping or sludge transfers to anaerobic tanks and/or chemicals addition may be employed. The sludge pumping and chemicals further add to OPEX, and the introduction of further tankage increases the capital costs to some extent.

Other key parameters affecting the rheological properties (see Immersed vs sidestream MBRs − flux and shear) of the sludge (solids concentration and temperature) do not vary significantly across large-scale municipal applications; the sludge solids concentration is normally around 8−12 g/L in the process tank and 10−15 g/L in the membrane tank for an immersed system. For a sidestream system subjected to high loads, the solids concentration may be higher.

Generally speaking, the rate of transfer between the membrane and process tank is 4−5 times the rate of the flow of water through the process (or 4−5 Q (see MBR operation and maintenance − membrane side)). Flows between different process tanks to achieve nutrient removal are somewhat lower.