Emerging membrane technologies

1. Forward osmosis

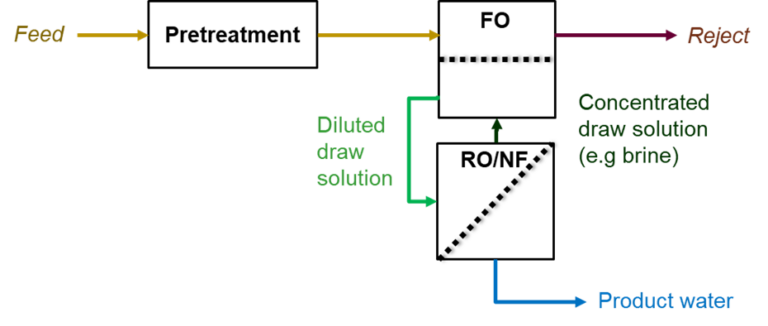

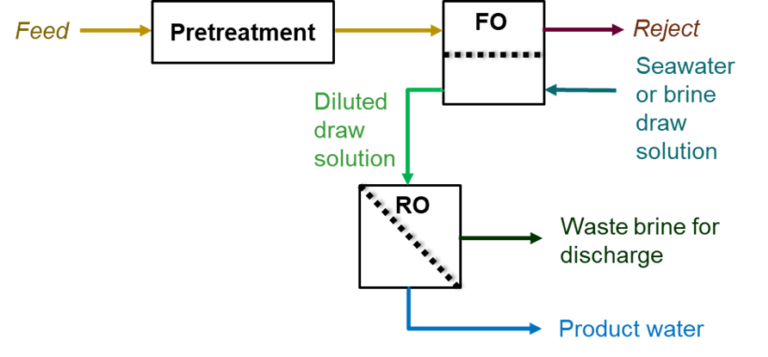

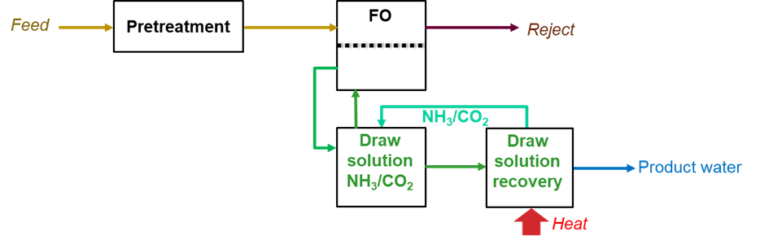

Forward osmosis (FO) is an emerging technology based on the principle of the naturally-occurring phenomenon of osmosis, whereby diffusion of water through a semi-permeable membrane is driven by the osmotic gradient across the membrane. To achieve this transport of water a highly concentrated solute, called the ‘draw solution’ (DS) is placed on the permeate side of the membrane to draw the pure water from the feed to the concentrated side.

As the DS circulates through the membrane surface, more water is extracted which dilutes the draw solution. A regeneration/replacement step is therefore required to simultaneously recover the water and re-concentrate the DS. FO is therefore a two-step process:

- the osmotic transfer of water from the feed into the DS, and

- the separation of the permeated water from the DS, and the simultaneous recovery of the latter.

The first of these steps is an inherently low-energy process, incurring only a fraction of the energy consumption associated with classical reverse osmosis (RO). Because permeation is non-pressurised, membrane fouling is not significant. Extensive pre-treatment of the feed water is thus not normally required, and membrane cleaning less aggressive than for RO or nanofiltration (NF).

Recovery of the DS, however, is technically challenging and essentially a high energy process. Because of this, FO is sometimes envisaged as being more viable for ‘open-loop’ systems where no recovery of the DS is required.

DS recovery is often based on RO or NF to separate the electrolyte used for the DS from the pure water product. However, this then incurs a similar energy demand to that of conventional RO/NF application to the original feedwater.

An alternative draw solution which can be recovered without using dense membrane (RO or NF) separation is ammonium carbonate (NH4)2CO3. This electrolyte dissolves in water to produce the ammonium cation (NH4+) and the carbonate anion (CO32-), generating the required osmotic pressure for the DS. On heating the solution to ~60°C the solution disproportionates to generate ammonia (NH3) and carbon dioxide (CO2) which can be degassed from the solution and leave the pure water product behind. The gases can then be re-dissolved in to generate the DS for use in the FO separation process.

Despite the significant research interest in FO, up until the end of 2020 there have been very few installations based on the process. A 2019 review of the status of implementation (Awad et al, 2019) suggests that issues remain with DS recovery, low sustainable fluxes (for seawater desalination in particular) and product water purity. As of January 2022, there were <10 suppliers of FO technologies worldwide, with little evidence of implementation.

2. Membrane distillation

Membrane distillation (MD) employs a micro-porous hydrophobic membrane as a semi-permeable barrier between two solutions at different temperatures, creating a trans-membrane thermal driving force. Since the membrane is hydrophobic, with pore size in the UF−MF size region, only vapour can pass through it, driven by the temperature gradient which creates a corresponding vapour pressure difference.

The volatile constituents of the heated feedwater, which may include water itself if the feed temperature and vapour pressure difference are sufficiently high, evaporate through the pores to the lower-vapour pressure permeate side where they are condensed. If the volatile matter content in the feed is low and only water is permeated then the permeate generated is demineralised water.

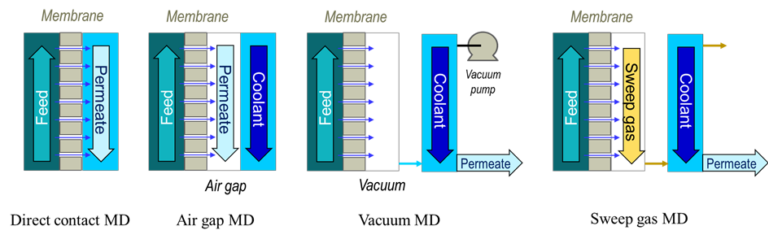

Different module configurations exist for generating the vapour pressure difference:

- Direct contact membrane distillation (DCMD), where the permeate-side condensate (or clean water, if no volatile species are present) is in direct contact with the membrane

- Air gap membrane distillation (AGMD), where the condensate surface is separated from the membrane by an air gap and the permeate vapour condenses at the coolant−air gap interface

- Vacuum membrane distillation (VMD), where the permeate vapour is extracted using a vacuum and subsequently condensed, and

- Sweep gas membrane distillation (SGMD), where a gas is used to sweep the permeate vapour to the condenser.

For VMD and SGMD the permeate vapour is condensed outside of the membrane module.

The viability of MD compared with conventional RO desalination is constrained by the attainable flux, which is lower than that associated with RO, and the relatively high cost of the membranes themselves. MD also relies on a low-cost heat source to be economically viable. As of January 2022, there were <10 suppliers of MD technologies worldwide, with little evidence of implementation.