Containerised/packaged plants

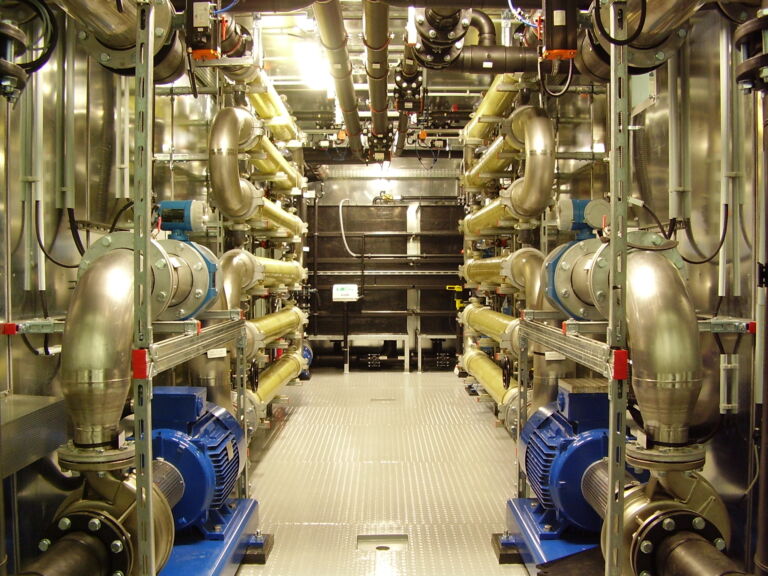

Containerised, or packaged, wastewater treatment plants are systems where all the wastewater equipment is preinstalled within a single transportable container or skid. This includes the instrumentation and control components as well as the unit processes.

Since all the required equipment is preinstalled and factory tested prior to shipping, the onsite installation work demanded is largely limited to:

- preparation of the site (building the base or excavating the hole for the plant, installing the power supply and, if required waste collection and mains water supply), and

- connecting to the influent and treated lines, the electrical supply, and other services.

This degree of simplicity (‘plug-and-play’ or ‘turnkey’), which then permits rapid installation, is one of the attractive features of containerised plants. Also, since they are self-contained all-in-one modules, the required flow capacity can be met by installing further modules – though there reaches a point where this becomes less cost effective than constructing a bespoke plant on site in the conventional manner.

Packaged plants for transporting internationally are necessarily constrained in size by the internal dimensions of a standard ISO shipping container (12 m long x 2.4 m wide x 2.4 m high for a standard 40’ ISO shipping container). This limits the treatment capacity a single container can offer. An MBR housed in a single 40’ container can treat a maximum flow of between 30 and 100 m3/d, or up to 500 population equivalent, depending on the selected membrane technology.

Since the plant is pre-fabricated and tested at the factory, it must be assured that it meets the necessary regional, national and/or international standards which may apply to the product prior to shipping. These generally include the assumed flows and loads (i.e. the feed water quality), materials of construction, compliance with any electrical wiring regulations, security against unauthorised entry on site and robustness to both site climatic conditions and interrupted electrical supply.

There are a number of providers of MBR packaged plants worldwide, predominantly based on the immersed membrane configuration but with some sidestream technology providers offering their skids in containerised form. They can be provided in two containers, with the biological process tank and pre-screening in one and the membrane skid or tank and all ancillary equipment for pumping, aeration, membrane cleaning and process control in another.