Sucking air − are MBRs too expensive, too difficult to operate?

Simon Judd has over 35 years’ post-doctorate experience in all aspects of water and wastewater treatment technology, both in academic and industrial R&D. He has (co-)authored six book titles and over 200 peer-reviewed publications in water and wastewater treatment.

Regardless of the manifest benefits offered by MBR technology with respect to the amazingly high water quality produced, it’s hard to get away from the not-unwarranted perception that they are too expensive to buy, use too much energy, and present a whole host of operational problems.

Our recent survey has once again highlighted the challenge posed by membrane clogging, perceived as being attributable to insufficient screening, as well as over ambitious design fluxes, poor air distribution and, in the case of industrial effluents, membrane fouling and cleaning. Moreover, it’s reasonable to presume these things to be inter-related, as the article suggests.

With the benefit of hindsight, it was perhaps a mistake not to make this year’s survey open-ended, as the original one was. It seems almost certain that, were this to have been the case, at least a few respondents would have mentioned the other 'f' word − foaming.

Indeed, a survey conducted by Aalborg University a few years ago indicated that a large number of MBR installations contained high levels filamentous bacteria, which is hardly likely to ameliorate foaming problems. Given that MBRs are more vigorously aerated than conventional activated sludge processes, foaming is inevitably exacerbated. It is also unfortunate that filamentous bacteria generate a sludge which is more hydrophobic, and thus more highly fouling.

Given the above, and in particular the key issue of energy demand, it is perhaps no surprise that there is increasing interest being shown in anaerobic MBRs, where all aeration distribution and energy demand issues are dismissed at a stroke. Unfortunately, anaerobic flocculant biomass is significantly more fouling in nature than the aerobic stuff, yielding rather modest fluxes.

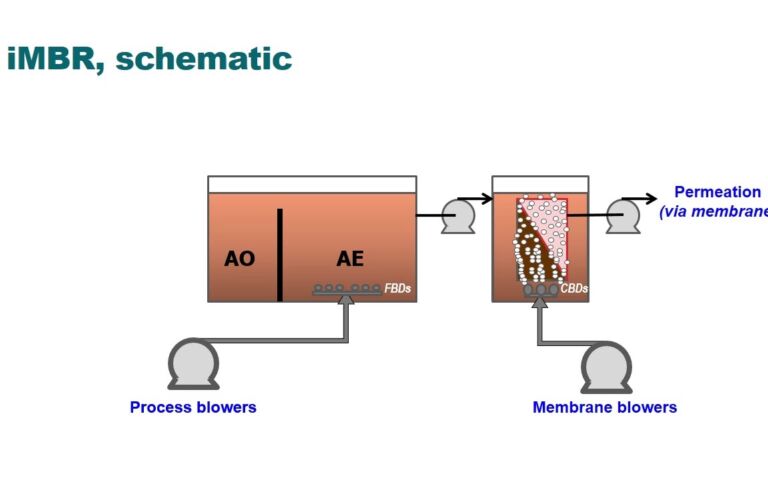

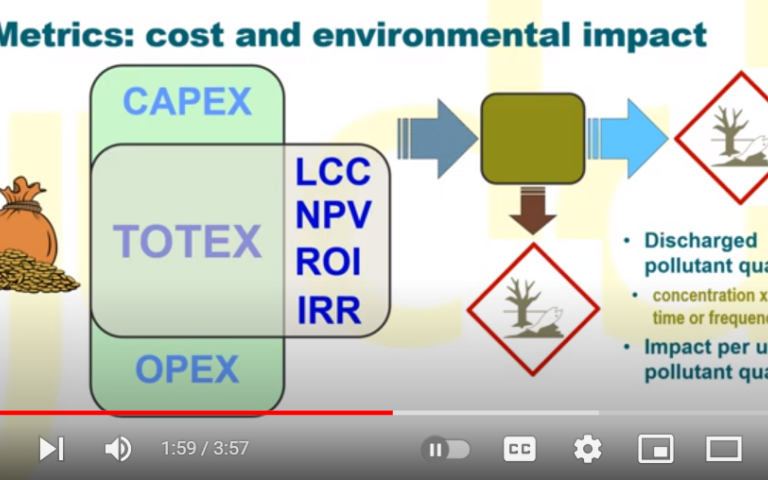

This is great news for the membrane suppliers, since it necessarily increases the membrane area demanded. For the purchaser, the cost benefit of a reduced operational energy demand has to be weighed against the increased capital cost and process complexity. Currently, anaerobic processes are only considered viable at high organic concentrations, and the conventional anaerobic MBRs (anMBRs) are sidestream in configuration with high pumping energies (although, obviously, zero aeration demand). Immersed anMBRs (aniMBRs) potentially offer lower energy demands, but maintaining membrane cleanliness becomes a serious bottleneck if air scouring cannot be used. Nonetheless, a rudimentary cost benefit analysis (Martin et al) suggests that aniMBRs may be cost competitive with conventional aerobic MBRs at COD concentrations above 1100 mg/L.

So, how close are we to a viable aniMBR technology? Such installations already exist for high-strength industrial effluents, though they are far outnumbered by the sidestream-configured MBRs. The challenge of ensuring viability of aniMBRs for comparatively low-strength and low-temperature feedwaters is considerable, and the limitation imposed by fouling is just one of the constraints faced.

It would be brave to predict that aniMBRs will become the municipal wastewater treatment technology of choice in 20 years − when energy costs have presumably hit astronomical levels. Equally, it would be foolish to write them off. I should know: no-one was more fervent in dismissing anMBRs than myself 8−10 years ago.

And, as is so often the case, no-one is more zealous than the converted.