Clogging: sludging and ragging (braiding)

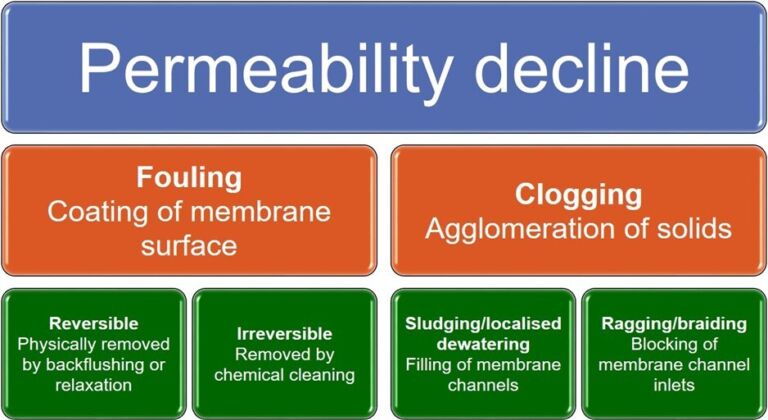

Clogging is the general term used to describe the tendency of the sludge (or mixed liquor) to block the membrane channels, impeding the flow of air and sludge. There are two types of clogging:

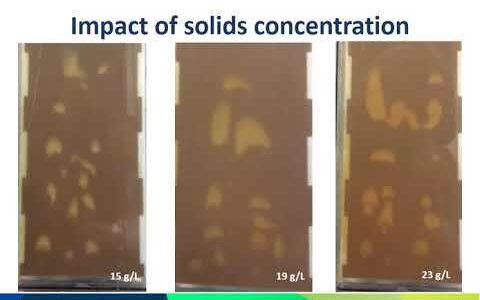

- ‘sludging’, which is the filling of the channels with a semi-solid sludge layer, and

- ‘ragging’ or ‘braiding’, where long rags or braids are formed from fibrous material in the sludge.

Clogging is to be distinguished from ‘fouling’, which is an entirely surface phenomena and is almost always largely removed by the chemical clean. Chemical cleaning has almost no impact on clogging, since the sludged solids or rags are associated with the space between the membranes rather than the membrane surface.

Rags can form from small lengths of textile in the wastewater. These filaments may be no more than a few mm in length, but agglomerate over a period of a few days to form rags which can be almost a metre in length. Once formed these rags cannot be dispersed and, since they are almost neutrally buoyant, cannot be settled out. They instead become entangled with the infrastructure within the membrane tanks, including the membrane aerators (if they are not integrated into the membrane module), as well as blocking the entrance to the membrane channels.

Very little is known about the causes of sludging and braiding. Laboratory tests suggest that sludging relates to filterability and solids concentration, and possibly bulk viscosity, of the sludge. An examination of different textiles indicates that cotton wool has the greatest tendency to form rags. Regardless of the causes, anecdotal evidence suggests that both sludging and ragging can be significantly reduced by selection of an appropriately conservative screen.