MBRs for reclamation and reuse

There are three types of water reuse applications where wastewater is reclaimed for some purpose:

- non-potable reuse (NPR), where the recovered water is used for some purpose other than potable supply (e.g. irrigation, industrial process water, etc),

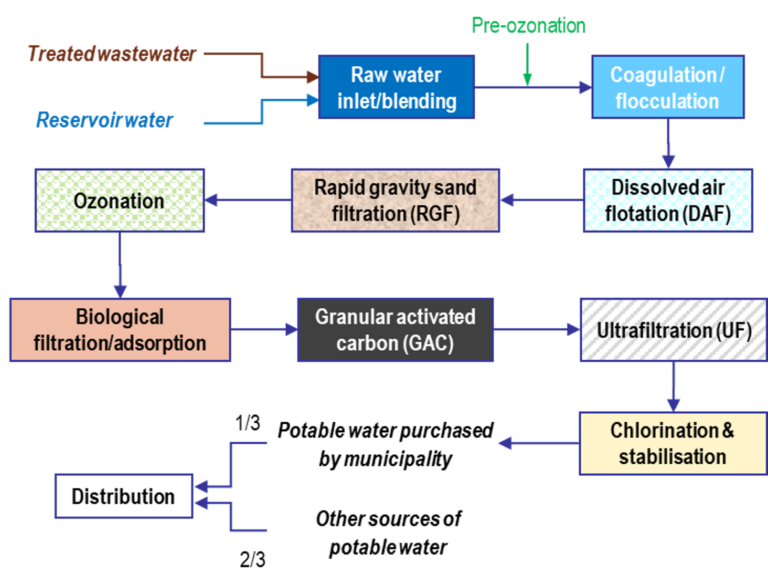

- indirect potable reuse (IPR), where water recovered from municipal wastewater passes through an ‘environmental buffer’ before being used as a supply of potable water, and

- direct potable reuse (DPR), where the recovered municipal wastewater is used for potable supply without an environmental buffer.

The environmental buffer, which may be a lake, river, or a groundwater aquifer, provides additional protection through dilution or removal by filtration (for aquifers), photolysis (for surface waters), or biological degradation. Whilst this performance can be attained by additional unit process technologies for direct reuse, DPR incurs an additional risk from process upsets (e.g. membrane breaching or UV lamp failure) which require addressing through advanced automation and real-time process performance monitoring.

Non-potable reuse, NPR

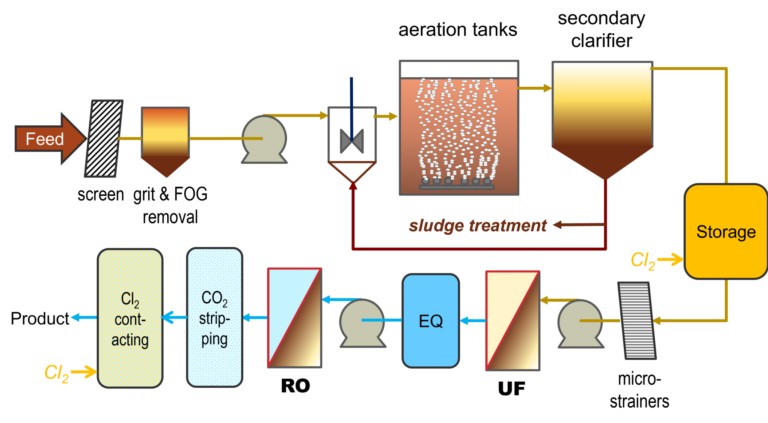

NPR installations have less strict product water quality requirements than those for IPR or DPR. These schemes often employ UF or MBR followed by RO as the main purification technologies, removing both suspended and dissolved impurities. The reclaimed water is frequently used for irrigation, though other potential uses include toilet flushing and laundering (for domestic applications), fire-fighting and industrial cooling or processes.

Feedwater sources for NPR may be either industrial effluent or municipal in origin. Reclaimed industrial effluents are normally reused on site as process waters in place of mains water, in which case the reclaimed water must normally be similar in quality to the mains water it is displacing. Recovered municipal waters may be employed either for industrial process water, irrigation, or other municipal or community applications.

There are a number of large, established NPR plants worldwide where municipal wastewater has been recovered for reuse as irrigation water, particularly in arid regions. This includes the 425 MLD plant at Sulaibiya in Kuwait, commissioned in 2005. As with the majority of reuse schemes, the process at Sulaibiya is based on the polishing of effluent from a conventional activated sludge (CAS) process with ultrafiltration (UF) followed by reverse osmosis (RO), providing 85% recovery overall.

There are additionally a significant number of relatively small reuse systems based on various industrial sites. These are predominantly in the food and beverage sector, and include MBR technologies installed upstream of RO skids whose permeate water displaces part of the mains water supply. Examples include the Kanes Foods site in Worcestershire in the UK and the Gippsland Water Factory in Australia.

Indirect (IPR) and direct (DPR) potable reuse

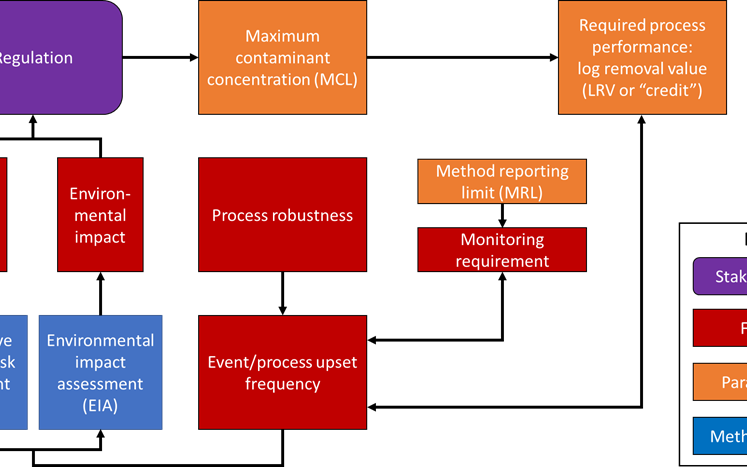

Key parameters in reclaiming wastewater for potable supply comprise:

- the legislated maximum contaminant level (MCL) of chemical pollutants in the treated water, as well as the process performance in terms of pathogen removal expressed as the log removal value (LRV)

- the minimum contaminant concentration measurable (MRL, the method reporting limit)

- the frequency of events (process failure and mitigating factors, including environmental) leading to degradation of treated water quality or some other onerous outcome (such as pollution from residuals), and

- the impact of treated water quality degradation, or possible pollutant release, associated with the above events.

The risk of pathogen breakthrough can be determined by quantitative microbial risk assessment (QMRA), which requires extensive data sets for both the source water pathogen concentrations and the performance of the unit process. In particular, data on the likelihood, nature and impact of process failure (or 'hazard events') on downstream pathogen levels is required.

Environmental impact assessment (EIA) becomes important when:

- the environmental buffer used is uncontained, such as a river or canal, and/or

- waste streams generated, such as reverse osmosis concentrate, are discharged to the environment.

There are a number of installations which reuse municipal wastewater for potable supply, predominantly in the US, though the oldest is a DPR plant installed at Windhoek, Namibia (the Goreangab Water Reclamation Plant). There are additionally multiple installations in Australia, Singapore, and Southern Africa. Nearly all are based on CAS as the biological treatment stage followed by polishing. More than 75% employ at least one membrane technology (MF, UF and/or RO) in the treatment process, with around 75% also using UV irradiation − with half of these employing UV as part of an advanced oxidation process (AOP). Half of all municipal wastewater IPR/DPR installations worldwide use membrane filtration (MF or UF) in combination with downstream RO.

The few planned municipal DPR schemes which encompass MBR technology are the Cloudcroft installation in New Mexico and the very large plant at Tuas in Singapore.