Trickling filters and Rotating biological contactors

Passive aeration fixed film processes

Tricking filters (TFs) and rotating biological contactors (RBCs) are examples of fixed film processes. They employ passive aeration: oxygen from air absorbs into the water without the use of pumping.

Both processes, and TFs in particular (first implemented in the 1890s), are established biological treatment processes in the treatment of municipal wastewaters. As with conventional activated sludge (CAS), they are best employed downstream of primary sedimentation.

Along with constructed wetlands, these processes incur the lowest energy consumption of all wastewater treatment processes. Values range between 0.05 and 0.2 kWh/m3 for either processes, the value depending on the required extent of BOD removal and nitrification/denitrification (Henrich and Marggraff, 2013; Williams, 2012). Energy consumption is thus between 30 and 50% that of the CAS process. Energy is needed primarily for mechanical rotation, either of the sprinkler arms for the TF or the media discs for the RBC, rather than for pumping air.

The processes also tend to produce a more readily dewaterable sludge than CAS, the waste being excess biofilm which sloughs off from the media. They generate little noise, and are robust to changes in loading. However, they can generate nuisance odours, attract flies, demand a permanent power supply, have high investment costs, and the mechanical element necessitates diligent and regular maintenance.

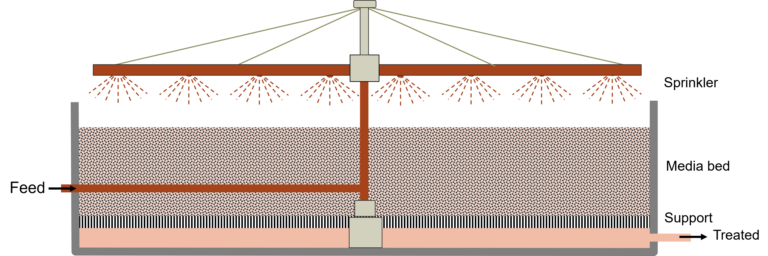

Trickling filters

TF media can be crushed rock, porous ceramic, lightweight expanded clay aggregate (LECA), packed plastic media, 3D structured media, or even wood. These media significantly differ in specific surface area and voidage, ranging from 40−80 m2 per m3 and 50−60% voidage for rock media to 100−250 m2 per m3 and >97% voidage for plastic media.

In a TF, the wastewater 'trickles' through media, packed into a cylindrical vessel, via rotating distributor arms fitted with sprinklers above the bed. The rotating motion can be either hydraulically or electrically driven.

The media is placed onto a porous support through which the treated water flows. Oxygen then enters the system as air through ventilation openings at the base of the filter.

The biological treatment takes place in two stages. In the upper section heterotrophic bacteria dominate, converting the BOD to CO2. Nitrifiers are largely absent in this zone since they are slower-growing. At greater depths, BOD concentrations decrease to a point – roughly 20 mg/L – where heterotrophic biomass growth is reduced enough to allow nitrifiers to proliferate.

The influent BOD load and bed height then determine the extent of nitrification. For stone media the height is 1−2.5 m, whereas the more porous plastic media can have depths greater than 13 m and correspondingly higher loading rates.

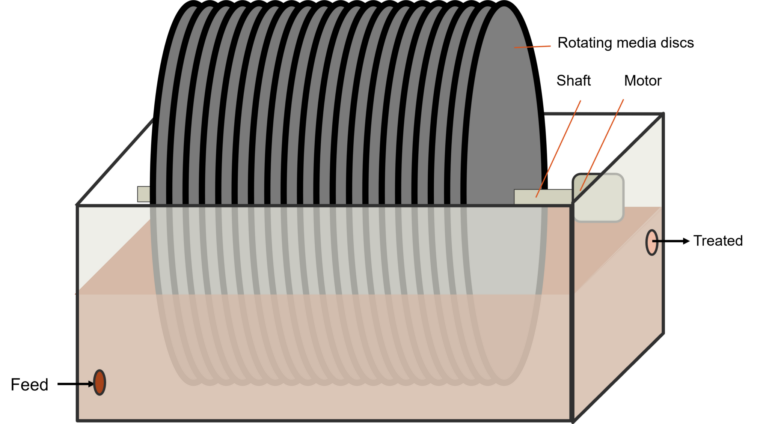

Rotating biological contactors

In rotating biological contactors (RBCs – also called rotating biological filters) the media comprises stacks of 0.6−3 m diameter discs mounted on a horizontal shaft and rotated while partially immersed in a trough through which the wastewater flows. The discs are most commonly made of high-density plastic sheets (e.g. polyethylene, polystyrene or polyvinylchloride) and are usually ridged, corrugated, or lattice-like to increase the specific surface area.

The microbial community growing on the disc media surface is alternately exposed to the atmosphere and the wastewater. This permits both aeration (when the disc is exposed to the air) and assimilation of dissolved organic pollutants and nutrients for their degradation (when immersed in the wastewater) over the course of a single cycle.

The biochemical process is optimised by adjusting the speed of rotation (1−2 RPM) and the depth of submergence – normally between 40 and 80%. In some designs, air is added to the bottom of the tank to provide additional oxygen in case of high-strength influents, which increases the process biochemical efficiency but also the energy consumption.

The degradation process is similar to the one in a TF with a high rate of recirculation. The longer contact time provided by RBCs from the rotating action allows for greater removals of organic matter and more intense nitrification than obtainable by TFs. The disc media can be designed to retain large amounts of biomass, though this can then create issues with clogging.

Units may be installed above or below ground level. Access to all moving parts and controls is required, and proper venting of the units essential, especially when natural ventilation is being used to supply oxygen. The susceptibility of the discs to damage by sunlight, wind and rain can necessitate covering with a housing to protect them, as well as to sustain the temperature.