Membrane cleaning

Cleaning of membranes is necessary to maintain the permeability at a sustainable level, thereby achieving the required permeate production rate and reducing the energy consumption.

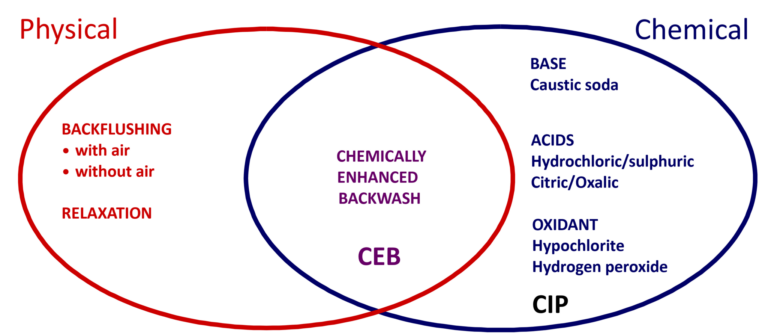

Membrane cleaning can be by physical or chemical means. Generally, the term ‘cleaning’ in membrane technology is taken to mean chemical cleaning.

Physical cleaning is normally achieved either by ‘backflushing’, i.e. reversing the flow back through the membrane, or ‘relaxation’ – ceasing permeation whilst continuing to scour the membrane with air bubbles (for an immersed process) or the crossflow (for the sidestream configuration). These two techniques may be used in combination, and backflushing may be enhanced by combination with air.

Physical cleaning removes gross solids attached to the membrane surface, generally termed ‘reversible’ or ‘temporary’ fouling, whereas chemical cleaning removes more tenacious material often termed ‘irreversible’ or ‘permanent’ fouling. Physical cleaning is less onerous than chemical cleaning in that it is generally more rapid, demands no chemicals, generates no chemical waste and is less likely to degrade the membrane. However, its effectiveness is limited, such that chemical cleaning is always required at some point.

Since the original virgin membrane permeability is never recovered once a membrane is fouled through normal operation, there remains a residual resistance which can be defined as ‘irrecoverable fouling’ which may build up over a number of years and may ultimately determine membrane life, though membrane life can also be determined by integrity failure.

Chemical cleaning usually employs sodium hypochlorite, an oxidative chemical, in combination with mineral or organic acids (most often citric acid). These two chemicals are applied sequentially (i.e. one immediately following the other) with the acid clean often scheduled less frequently than the hypochlorite clean. Cleaning is normally conducted without removing the membrane from the tank or skid (and is hence termed a ‘clean in place’ or CIP). If chemical cleaning is combined with backflushing this is referred to as a ‘chemically-enhanced backflush’ (CEB). CEBs are routinely carried out on a twice-weekly to monthly basis for backflushable membranes (most usually hollow fibres), regardless of the state of the membrane permeability. Such protocols are normally referred to as ‘maintenance’ cleans.

Chemical cleaning employed specifically to recover permeability demands higher reagent concentrations and longer contact times than maintenance cleans. Such ‘recovery cleaning’ is not always effective – normally because the membrane has become clogged with sludge solids, a phenomenon often referred to as ‘sludging’. In municipal wastewater treatment, membranes may sometimes also become clogged with ‘rags’ (or ‘braids’) formed from aggregated filamentous matter (specifically textile fibres such as cotton wool) in the feedwater. This is usually referred to as ‘ragging’ or ‘braiding’.

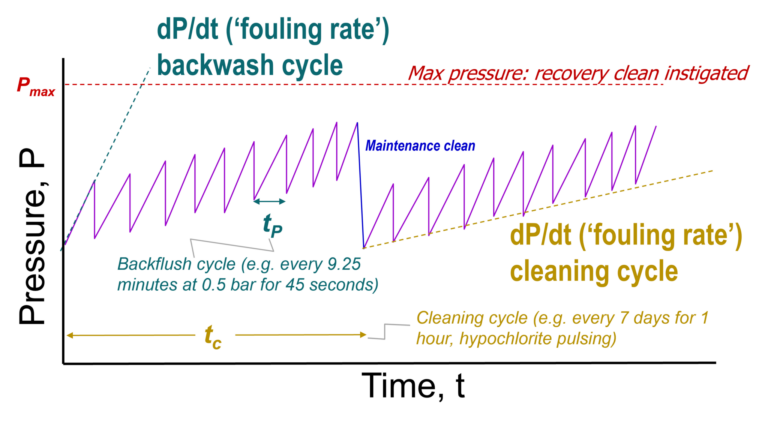

Membrane cleaning is often the only membrane operational parameter which is within the control of the operator. There is normally a maximum TMP (or minimum permeability) beyond which operation is undesirable due to the increased risk of irrecoverable fouling or clogging.

Both physical and chemical cleaning then impact on the production rate, such that the net flux J' is always less than the instantaneous flux J:

where Jb is backflush flux (normally 1−2 times the operating flux), tp and tc are the cycle times for the physical and chemical cleans, and τp and τc are the corresponding cleaning durations (see figure below).

Typically, for an HF iMBR, backflushing of 30−60 s duration (τp) is applied every 10 minutes (tp) and maintenance cleaning (tc) scheduled weekly, and takes roughly two hours in duration (τc). For an iFS membrane, which is generally not backflushable, only chemical cleaning is used.

Neither the routine physical clean nor the chemical clean can be expected to counter clogging, which demands manual intervention (removal of the immersed membrane from the tanks) to remove the agglomerated material. This can be conducted with water jetting if the membrane is sufficiently robust. Clogging is significantly more onerous than fouling, and does not appear to relate to the concentration of recognised foulants such as extracellular polymeric substances or colloidal organic material.