MBR operation and maintenance

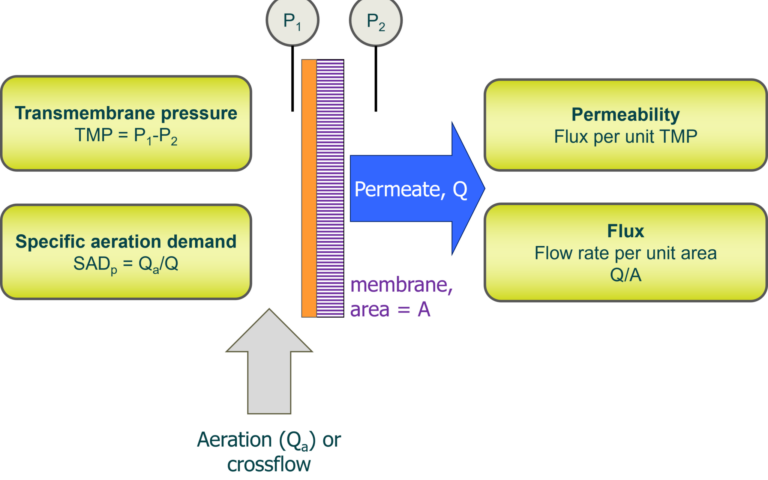

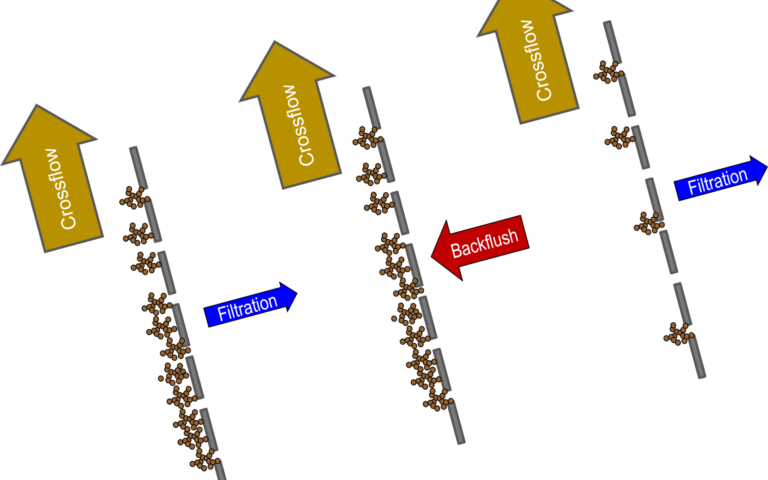

The principal MBR design parameter on the membrane side is the permeate flux. The flux required will then determine the various operating parameters and protocols for maintaining the membrane permeability.

On the biological side, O&M parameters mainly comprise the hydraulic and solids retention times, and sludge recycle rate. These parameters, in combination with the feedwater characteristics and load, determine the sludge yield and food to micro-organism ratio.