How is membrane filtration technology used in wastewater treatment?

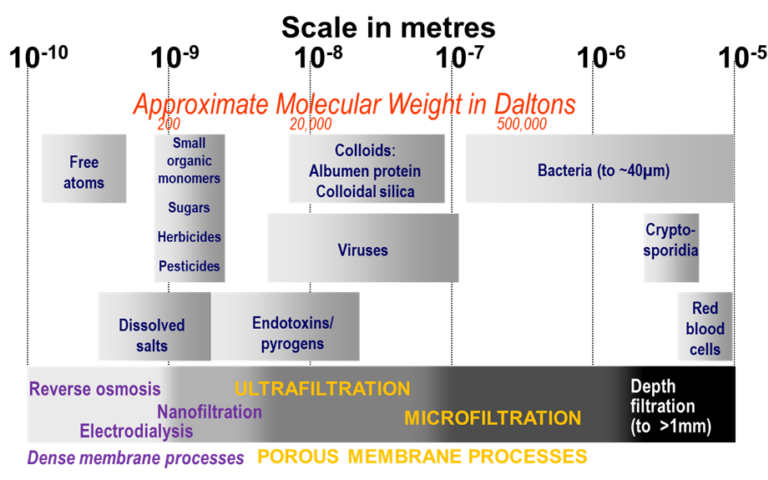

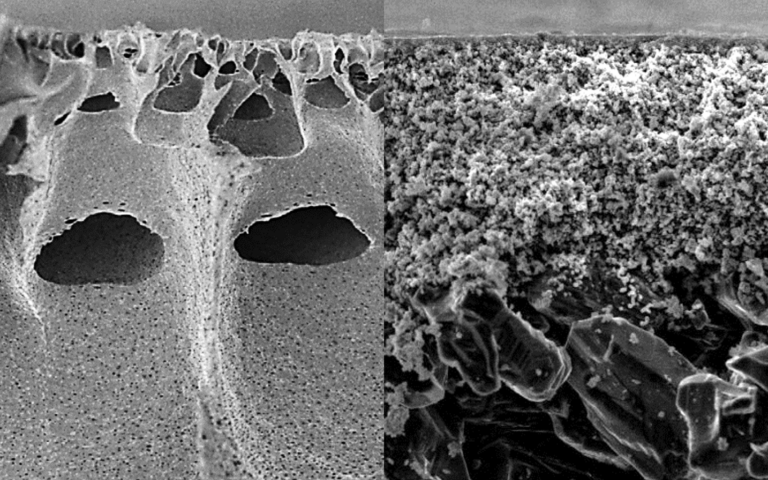

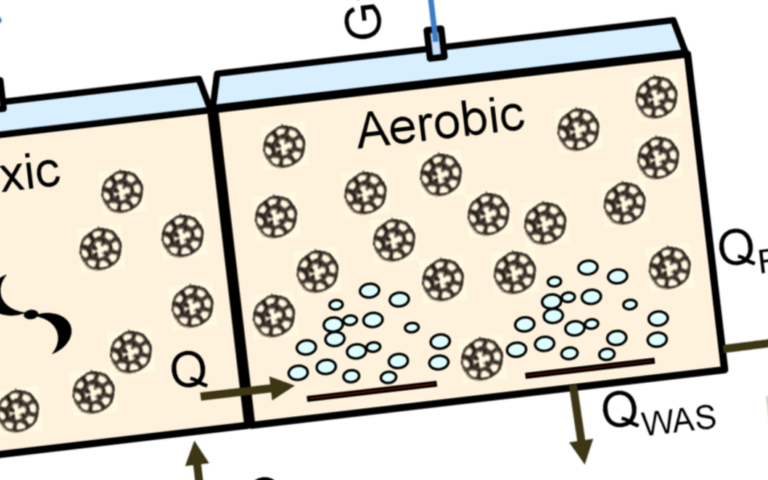

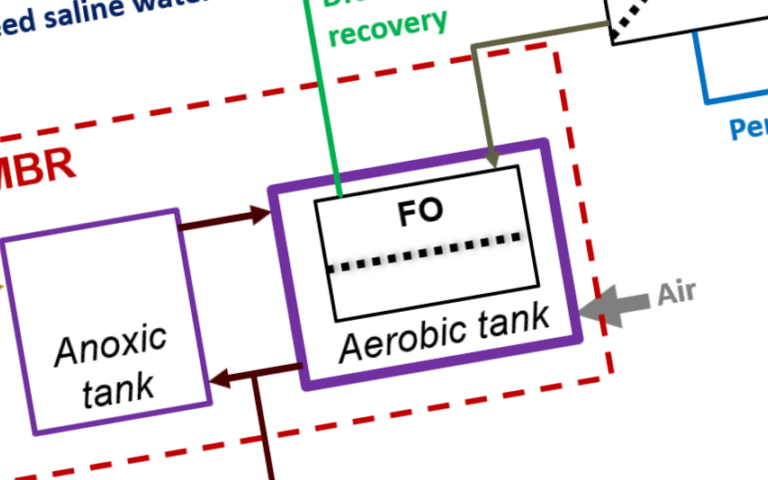

Membrane technology used for removing solids in wastewater treatment is usually based on ultrafiltration or microfiltration. The membranes can be introduced either as a separate unit operation downstream of the biological step, or integrated into a biological process as an MBR.