What are MBRs?

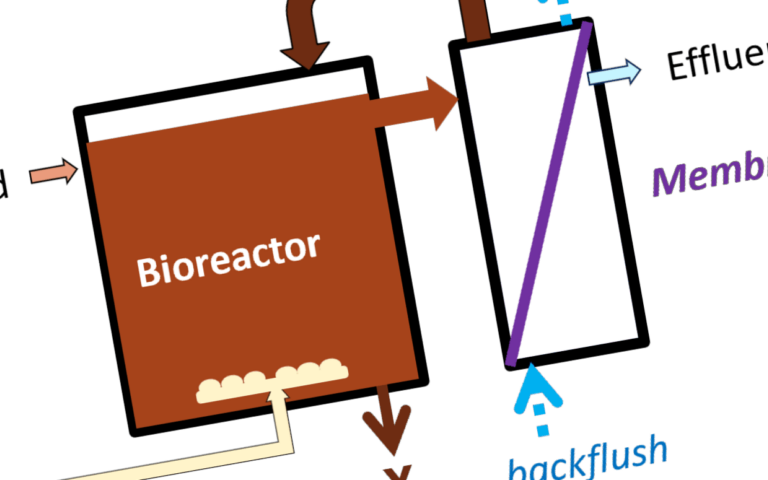

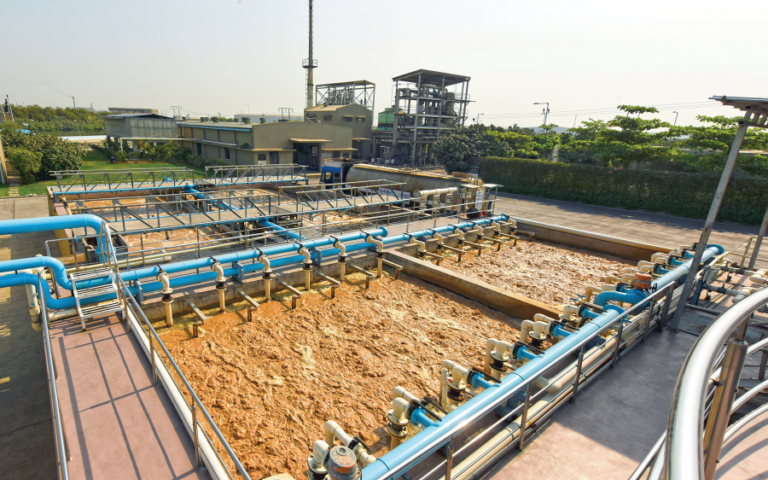

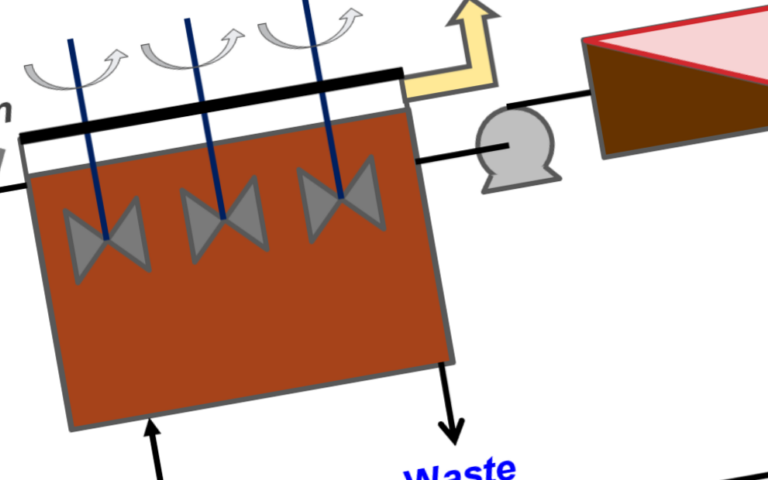

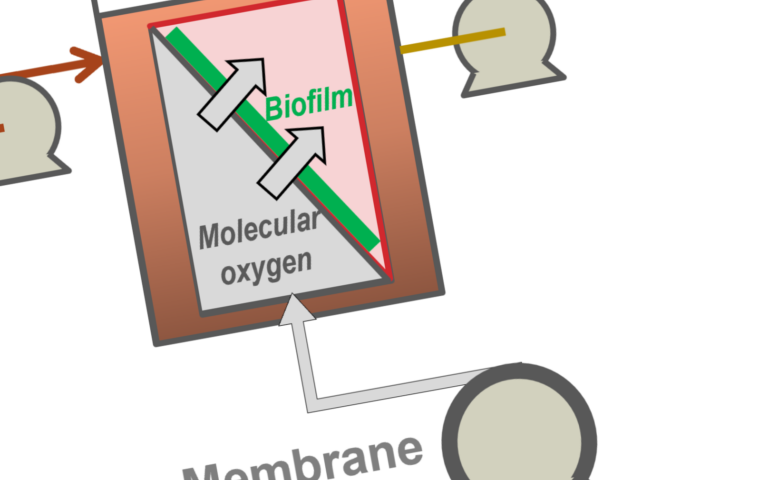

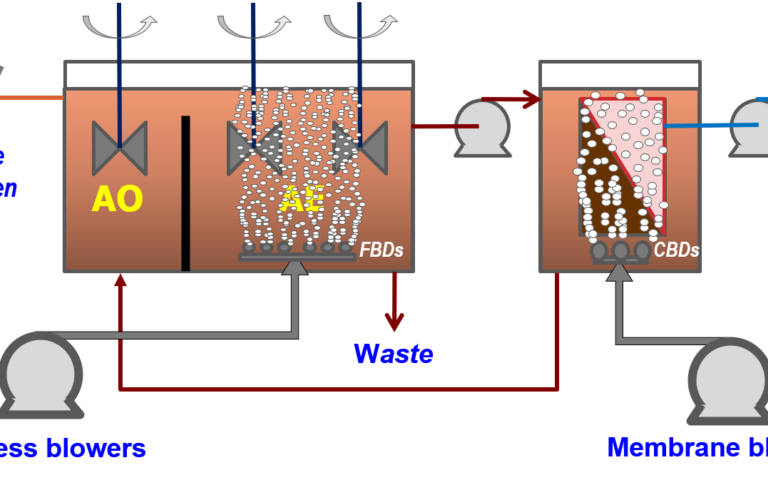

A membrane bioreactor is essentially a version of the conventional activated sludge (CAS) process. While CAS uses a settlement tank for retaining the mixed liquor suspended solids, an MBR uses a membrane for near-complete solids retention.