Fundamentals of MBR design

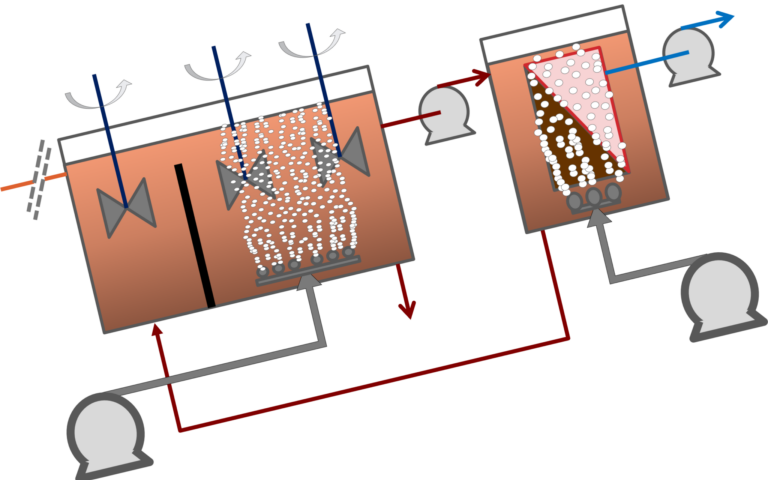

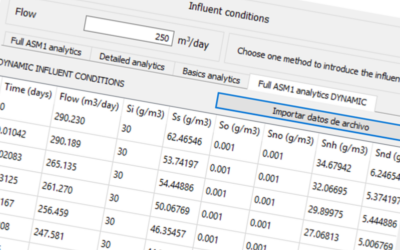

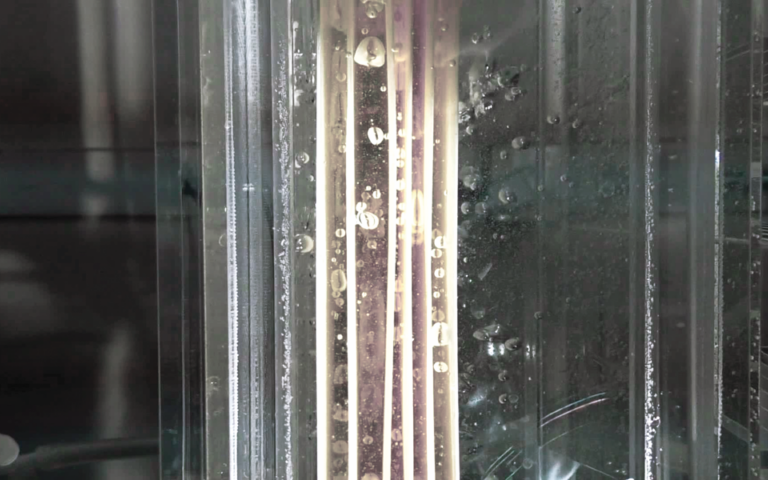

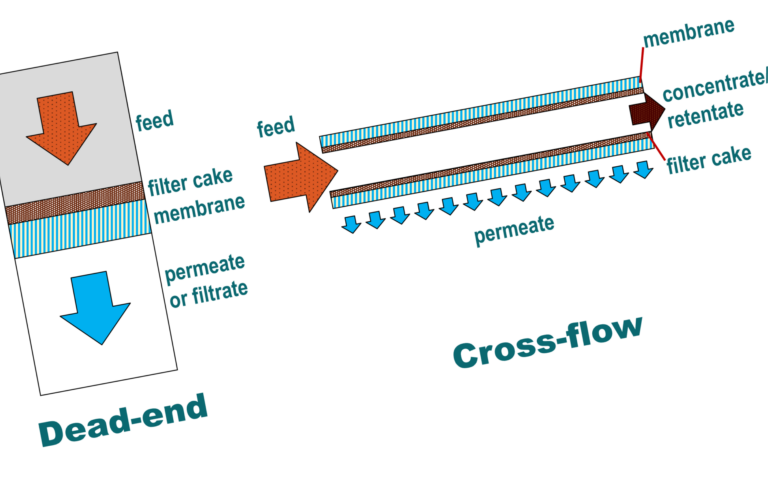

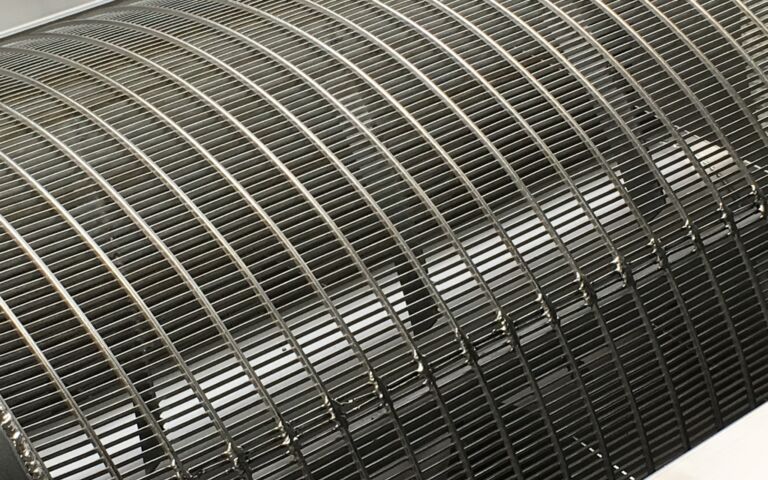

The design of a membrane bioreactor system largely relates to the configuration of the membrane separation process and biotreatment process stages, as well as the membrane configuration (its geometry and the direction of the permeate flow).