Foaming in membrane bioreactors

Chemical and biological foam

Foaming in activated sludge plants is sometimes described as 'floating biomass' and has been attributed to the combination of:

- anthropogenic surfactants (detergents)

- biosurfactants (formed from micro-organisms) and/or

- filamentous bacteria.

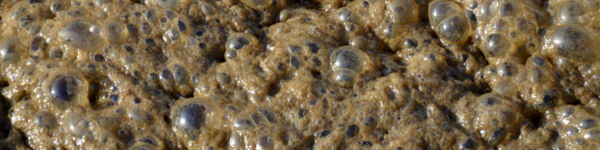

There are essentially two types of foam: chemical and biological. Chemical or biochemical foams are fragile and readily dispersed. They are attributable to the surfactant content of the sludge and can be reduced by dosing with surface active chemicals which destabilise the foam directly. Biological foams have a significant micro-organism content, and are more stable and onerous than purely chemical foams.

Biological foam in conventional activated sludge (CAS) plants is regarded as a three-phase matrix, comprising gas bubbles, liquid (wastewater) and solid particles (the filamentous bacteria). Filamentous micro-organisms are those whose cells are not separated following cell division and so tend to grow in the form of ‘filaments’. They are hydrophobic in nature, such that they tend to become attached to the air bubbles introduced by the aerators and float to the top of the tank to form a stable foam.

Foaming in CAS plants is a well-known problem, causing loss of biomass when the foam builds to the point that it overtops the tank walls. It can only be countered once the filamentous micro-organisms responsible have been identified, since different organisms require different strategies for their control. Nocardia, for example can be removed by surface spraying with hypochlorite, whereas Microthrix parvicella can be countered by alum dosing. There are also proprietary chemicals available which are claimed to tackle biological foams.

The degree of foaming is reported as being related to the protein EPS concentrations (see Foaming in MBRs: measurement and evaluation). In MBRs, foaming sludges appear to yield lower membrane permeabilities, attributed to the higher hydrophobicity of foaming activated sludge.